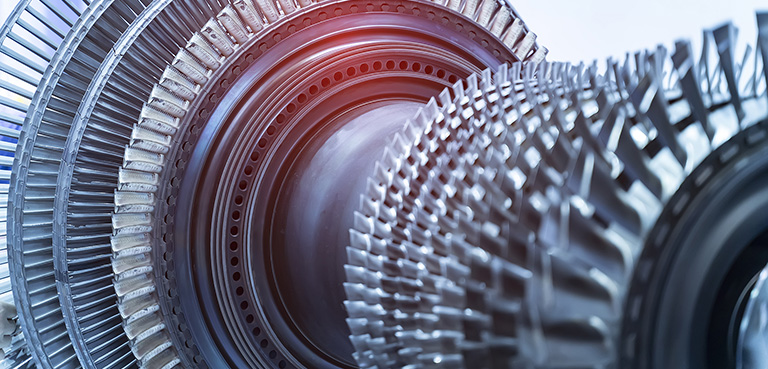

Ceramic and CBN for steel mill applicationsTools for mill roll turning| Ceramic and CBN inserts

High speed performance, longer tool life, and better part surface finish compared to carbide tools

Ceramic inserts effectively perform at high speed ranges

The best selection of Ceramic and CBN grades to successfully machine the application.

Light to heavy edge preparations to handle any cutting conditions.

Features

Ceramic insert advantage

- Harder material than carbide for high-speed machining

- A lack of metal in its composition allows it to minimize tool damage from heat

- Improved part surface finishes due to stable performance of alumina TiC ceramic.

- Cost effective alternative to CBN

CBN grades:

- High CBN content increases impact resistance

- Increased wear resistance machining abrasive materials

- B30 & B99 are ideal for carbide rolls

Tooling application

Turning mill roll materials

Features of insert grades

Insert grade selection

Scroll the table →

| Roll material | Application | Grade | Cutting speed (m/min) | Feed(mm/rev) | DOC(mm) | DRY | WET |

|---|---|---|---|---|---|---|---|

| High speed steel (HHS) roll | Rough to semi-finishing | Whisker ceramic WA1/WA5 | ~ 40 | 0.3 - 0.5 | * 5-15% of insert diameter (approximate) | ● | - |

| Finishing | CBN B22/B36 | ||||||

| Hardened steel roll | Semi-finish to finishing | Alumina ceramic HC2/HC7 | 80 - 200 | 0.5 - 0.8 | ● | - | |

| Finishing | CBN B22/B36 | ||||||

| Cast iron roll Chilled iron roll |

Semi-finish to finishing | Alumina ceramic HC2/HC7 | 40 - 80 | 0.3 - 0.5 | ● | - | |

| Finishing | CBN B22/B36 | ||||||

| Cast iron roll Ductile cast iron rolls CPM rolls (ex. Powdered metal) Carbide rolls |

Rough to semi-finishing | Silicon nitride ceramic SX9 | 40 - 120 | 0.5 - 0.8 | ● | - | |

| Finishing | CBN B22/B36 | ||||||

| Carbide rolls | Rough to semi-finishing | Whisker ceramic WA1/WA5 | ~ 40 | 0.3 - 0.5 | ● | - | |

| Finishing | CBN B22/B36 |

Ceramic insert application guideline:

① shape characteristic

Edge strength increases as the insert geometry angle increases.

Note that as the insert strength increases so do cutting forces.

Ceramic insert application guideline :

② edge preparations

Insert damage can be reduced by increasing the edge preparation.

Insert machining stability will be improved during roughing.

Ceramic insert application guideline :

③ Minimize overhang

By minimizing the toolholder overhang the setup is more rigid and eliminates chatter. (a main cause of insert chipping)

Industry specific tools

NTK provides specialized tools with industry specific insert geometries and coordinated holders.

Case study

| Forming roll | |

|---|---|

|

|

|

|

|

|

|

|

|

HC7 | 2 pcs/ corner |

| Competitor's black ceramic | 1 pcs/ corner |

HC7 performed with 2 times longer tool life compared to competitor's black ceramic.

| Bending roll | |

|---|---|

|

|

|

|

|

|

|

|

|

WA1 | 2 pcs(6,000L)/ corner |

| Competitor's black ceramic | 1 pcs(3,000L)/ corner |

WA1 achieved twice the tool life compared to competitor's black ceramic.

Customer: "I had always used the same black ceramic product, but now I see the performance difference between products."

Tool lineup

Please check product catalog for tooling lineup

Useful information

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕 Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕 Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics

Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics How to Make Ceramic Cutting Tools from Scratch

How to Make Ceramic Cutting Tools from Scratch