Machining Heat-Resistant Super Alloys (HRSA) such as Inconel, Waspaloy, and other nickel-based alloys are one of the toughest challenges in modern manufacturing. These materials are essential in Aerospace and Energy industries because of their ability to withstand extreme temperatures and stress.

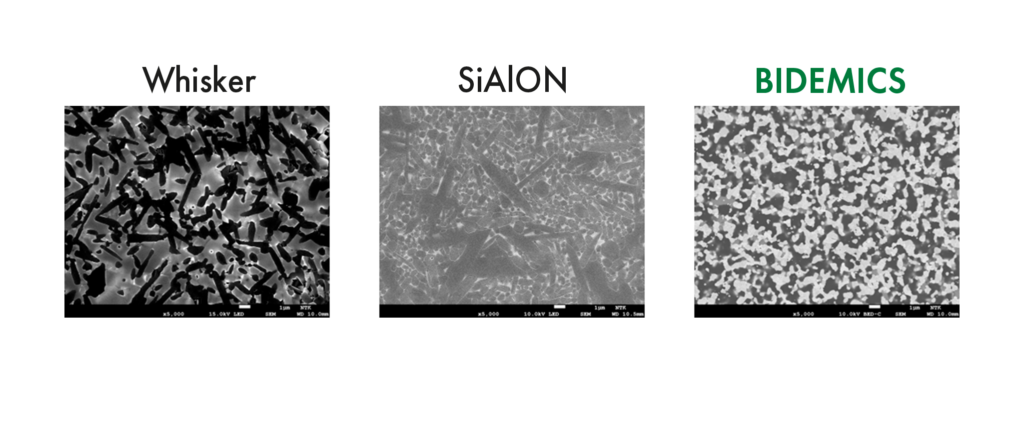

For tool manufacturers, HRSA represents a constant struggle: low cutting speeds, rapid tool wear, and inconsistent surface quality. Traditional carbide, SiAlON, or whisker ceramic tools often force compromises between productivity, tool life, and finish.

What is BIDEMICS?

BIDEMICS is NTK’s advanced ceramic–carbide composite cutting tool material, specifically engineered for HRSA machining. Unlike conventional whisker ceramics, BIDEMICS integrates fine alumina ceramic grains with tungsten carbide particles. This structure not only provides very high strength and hardness, but also helps disperse cutting heat effectively, enabling stable performance at ultra-high speeds.

Key physical properties:

- Hardness: ~HRA 95.5

- Bending strength: ~2100 MPa (≈ 2× whisker ceramics)

- Thermal conductivity: ~45 W/m·K (≈ 2× higher than whiskers/SiAlON)

This combination makes BIDEMICS both more wear-resistant and more heat-stable than conventional ceramic grades, explaining why it can run at cutting speeds up to 500 m/min where whiskers typically fail.

BIDEMICS is available in several grades to match different applications:

- JX1 (non-coated) – Optimized for ultra-high-speed turning and grooving of HRSA.

- JX3 (non-coated) – Improved toughness for turning and grooving with heavy loads.

- JP2 (TiN-coated)– Reliable finish turning, especially for Aerospace components with complex geometries.

Best Practices for Success

To unlock the full potential of BIDEMICS, NTK recommends:

- Using stable machines and toolholders to handle high cutting speeds.

- Applying the correct grade (JX1 for speed, JX3 for toughness, JP2 for finish).

- Optimizing cutting conditions according to depth of cut, feed rate and component geometry.

Long-Term Economic Advantage

BIDEMICS is a premium solution, and its initial cost is higher than whisker ceramics or other Ceramic grades. However, when applied under the correct machining conditions, BIDEMICS consistently delivers:

- Higher cutting speeds

- Longer tool life

- Reduced tool changes and downtime

In turbine disk turning, JX1 achieved twice the tool life of whisker ceramics at 240 m/min, and proved capable of increasing cutting speed up to 360–480 m/min while maintaining a similar tool life.

In next-generation alloys such as Rene104, JX1 demonstrated up to four times longer tool life compared to whisker ceramics, proving its capability to sustain both speed and durability under extreme conditions.

For finishing Turning, JP2 provides outstanding performance, achieving 3–5× higher productivity than whisker or SiAlON ceramics while maintaining a consistent surface finish (Ra < 0.5 µm) and predictable tool wear.

These results translate directly into lower cost per part and improved overall productivity. In practice, this means that even with a higher initial price, BIDEMICS provides a more economical solution in the long term for manufacturers facing the challenges of HRSA machining.

Real-World Success Stories

The strength of BIDEMICS is not only in lab testing, but proven in the field through customer applications and NTK’s Test Success Reports (TSRs).

- Heavy Face Turning of Valve Components (JX1 – more info)

In demanding heavy-duty valve machining, BIDEMICS JX1 achieved significantly longer tool life compared to whisker ceramics, even under heavy interruptions. The result: reduced tool changes and stable machining under aggressive conditions. - Aerospace Snubber Machining (JX1 – more info)

Aerospace snubbers, made from tough HRSA materials, require both accuracy and consistency. With BIDEMICS JX1, tool life increased and surface finish quality improved, reducing the risk of part rejection. - Internal Turning of Aerospace Sectors (JP2 – more info)

In a critical aerospace sector operation, JP2 demonstrated stable internal turning performance with superior finish and resistance to chatter, even with tool overhang challenges. - Aerospace Casings (JP2 – more info)

When applied to aerospace casings, JP2 consistently delivered improved wear resistance and surface finish, proving reliability across multiple real-world tests

Conclusion

With BIDEMICS, NTK is redefining what’s possible in HRSA Turning and Grooving. By combining ultra-high speeds, longer tool life, superior surface finish, and long-term economic advantages, BIDEMICS empowers manufacturers to meet the toughest demands of aerospace and energy industries.

Proven in real test cases and backed by strong technical performance data, BIDEMICS is more than just a new cutting tool material; it is the future of HRSA machining.