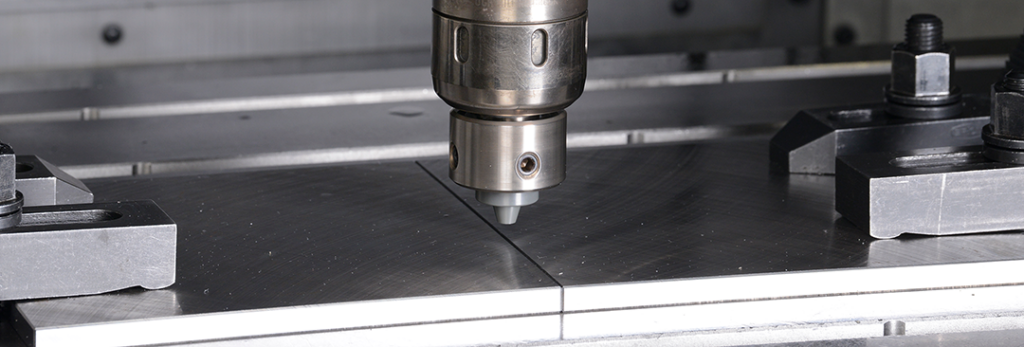

Friction stir welding (FSW) is a solid-state joining process, meaning it occurs without melting the workpiece material. It uses a specialized tool to generate frictional heat, which softens the material and allows it to be mixed and joined. The FSW tool is a crucial component, and its design and material properties significantly influence the quality and efficiency of the weld.

Applications of Friction Stir Welding

FSW has found applications across various industries due to its ability to produce high-quality welds in difficult-to-join materials. Key applications include:

- Aerospace: FSW is extensively used in the aerospace industry for joining aluminum alloys in aircraft structures. It provides superior mechanical properties and eliminates issues like porosity and cracking commonly associated with traditional welding methods.

- Automotive: The automotive industry utilizes FSW for joining lightweight materials such as aluminum and magnesium, which are increasingly used to reduce vehicle weight and improve fuel efficiency. Components like Battery case of EV and Chassis are commonly welded using FSW.

- Shipbuilding: FSW is employed in the shipbuilding industry for welding large panels and sections of aluminum ships and boats. It ensures strong, defect-free joints that are critical for the integrity of marine vessels.

- Railway: The railway sector uses FSW to manufacture components like high-speed train bodies and freight wagons. The process provides durable and reliable joints that can withstand the mechanical stresses encountered during service.

- Electronics: FSW is also used in the electronics industry for joining heat sinks and casings made of aluminum, ensuring efficient thermal management and structural integrity.

Advantages of Friction Stir Welding

FSW offers several advantages over traditional welding methods:

- High-Quality Welds: FSW produces welds with superior mechanical properties, including higher strength and better fatigue resistance. This is due to the absence of melting and solidification, which minimizes defects like porosity and cracking.

- Environmental Benefits: The process is environmentally friendly, as it does not require filler materials, fluxes, or shielding gases. This reduces emissions and waste, making it a greener alternative to conventional welding.

- Energy Efficiency: FSW is an energy-efficient process since it operates at lower temperatures than fusion welding. This reduces energy consumption and minimizes thermal distortion in the workpiece.

- Versatility: FSW can join a wide range of materials, including aluminum, magnesium, copper, and even some steels. It is also capable of welding dissimilar materials, which is often challenging for traditional welding techniques.

- Automation Potential: The FSW process is highly amenable to automation, making it suitable for high-volume production environments. Automated FSW systems ensure consistent weld quality and reduce labor costs.

NTK Solutions in Friction Stir Welding

NTK Cutting Tools, a leading provider of advanced tooling solutions, offers a range of innovative ceramic tools specifically designed for FSW. NTK’s ceramic tools bring unique benefits to the welding process, enhancing performance and efficiency.

Ceramic tools in friction stir welding (FSW) offer several benefits, particularly in demanding applications where traditional tool materials may not suffice. The main advantages of using ceramic tools in FSW include:

High-Temperature Resistance

Ceramic materials, such as silicon nitride, can withstand significantly higher temperatures than conventional tool steels and tungsten alloys. This property is crucial for welding high-melting-point materials like steel, stainless steel, titanium, and nickel-based alloys, where the frictional heat generated can exceed the capabilities of traditional tools.

Improved Wear Resistance

Ceramic tools exhibit excellent wear resistance, maintaining their integrity and performance over extended periods of use. This reduces tool wear and extends tool life, leading to cost savings in the long term due to fewer tool replacements and lower maintenance requirements.

Enhanced Tool Stability

Ceramic tools provide greater thermal stability during the FSW process. Their low thermal conductivity helps maintain a consistent temperature at the welding interface, resulting in more stable and uniform welds. This stability is particularly beneficial when welding materials that are sensitive to thermal fluctuations.

Reduced Contamination

Ceramic tools are less likely to introduce contaminants into the weld zone compared to metallic tools. This is particularly important in industries like aerospace and electronics, where material purity and integrity are paramount.

Cost Efficiency in High-Volume Production

While ceramic tools can be more expensive initially, their extended lifespan and reduced cycle time and maintenance needs can lead to cost efficiencies in high-volume production environments. The longer tool life means less downtime for tool changes and fewer interruptions in the manufacturing process.

In summary, NTK’s ceramic tools in friction stir welding offer significant benefits, particularly in high-temperature, high-melting-point material applications. Their durability, resistance to wear, and ability to maintain integrity under extreme conditions make them an excellent choice for advanced manufacturing processes, helping industries achieve superior weld quality and performance.