The medical parts manufacturing industry, particularly in the machining of bone screws, presents unique challenges due to the precision and quality required for critical implants. Bone screws, used in orthopedic and dental applications, demand superior machining processes to ensure strength, accuracy, and biocompatibility. With the increasing complexity of medical devices and the growing use of challenging materials such as titanium and stainless steel, manufacturers need tools and techniques that enhance productivity while maintaining the highest quality standards.

In response to these demands, NTK Cutting Tools offers a range of advanced solutions designed to address the specific needs of bone screw machining. This article will explore the current challenges in the industry, highlight key trends, and showcase NTK’s innovative tools, such as The Front Max (TFX), Thread Whirling (TW), and the NTK650 grade, that are engineered to optimize machining processes and improve overall productivity.

Current Challenges and Trends

Bone screw manufacturing faces a number of challenges. The need for high precision, flawless surface finishes, and tight tolerances is paramount. Medical parts like bone screws must meet stringent regulations, and machining these parts involves working with difficult-to-machine materials like titanium, stainless steel, and cobalt-chromium alloys. The rise of minimally invasive surgeries has further increased demand for smaller, more complex screws, adding complexity to the manufacturing process.

Current trends in the medical machining industry include:

- Increased Use of Titanium and Nickel-Based Alloys: These materials are biocompatible but notoriously difficult to machine due to their toughness and tendency to generate heat.

- Demand for Higher Productivity: Manufacturers seek to reduce cycle times while maintaining or improving tool life and part quality.

- Precision and Surface Finish Requirements: Bone screws must be free from defects, with smooth surfaces to ensure proper function in medical applications.

- Miniaturization of Components: As implants become smaller, the need for tools that can handle tiny parts with high precision has surged.

NTK Cutting Tools Solutions

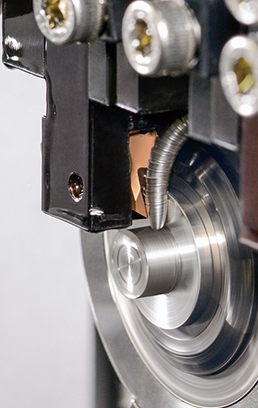

The Front Max (TFX) is designed for large depth-of-cut (DOC) operations with superior chip control and surface finish quality. It is particularly effective in machining operations requiring high stability and precision, such as bone screw production.

.

- Tangential Clamping System: Provides excellent stability, allowing for large DOC turning without chatter.

- Advanced Chipbreaker Design: Ensures efficient chip control, even in difficult cutting conditions.

- Increased Productivity: The tool’s ability to handle large DOC in a single pass significantly reduces cycle times.

- Coolant Through Tool Holders: Provides direct coolant supply to the cutting edge, enhancing tool life and surface finish.

The TFX is particularly well-suited for bone screws where high-quality surface finishes and precision are critical.

Thread Whirling (TW) is a highly efficient tool for threading applications, allowing manufacturers to produce bone screws with high accuracy in a single pass. This method is ideal for the long screws used in orthopedic and dental implants, offering substantial improvements in productivity over traditional threading techniques.

- One-Pass Machining: TW enables threading to be completed in a single pass, drastically reducing cycle times compared to conventional multi-pass methods.

- Optimal Chip Control: Special design technology ensures superior chip evacuation, which is critical when working with materials like titanium and stainless steel.

- High Precision: TW is designed for high-accuracy machining of long, multi-lead screws.

The unique design of NTK’s Thread Whirling system not only boosts productivity but also extends tool life, making it a cost-effective solution for high-value medical components.

NTK650 is a specialized PVD grade designed to tackle the most challenging materials in bone screw machining, including nickel-based alloys and titanium.

- HiPIMS Coating Technology: The High Power Impulse Magnetron Sputtering (HiPIMS) coating ensures a smooth surface and enhances the wear resistance of the tool.

- Prevents Coating Peeling: The smooth coating reduces imperfections and prevents built-up edges, common issues in medical part machining.

- Superior Heat and Wear Resistance: NTK650 is designed to withstand the high temperatures generated during the machining of tough materials.

- Extended Tool Life: Compared to competing grades, NTK650 provides longer tool life, particularly in materials like Inconel and Hastelloy, which are commonly used in medical components.

With NTK650, manufacturers can expect significant improvements in both productivity and part quality, especially when working with demanding materials.

Conclusion

As the demand for high-quality medical components like bone screws continues to rise, manufacturers face increasing pressure to improve productivity while maintaining precision and surface finish standards. NTK Cutting Tools offers a suite of advanced solutions tailored to meet these challenges. With The Front Max (TFX) for large DOC operations, Thread Whirling (TW) for efficient threading, and the NTK650 grade for machining tough materials, NTK provides the tools necessary for success in today’s medical machining landscape.

By embracing these innovations, manufacturers can stay ahead of the competition, producing bone screws with the accuracy and efficiency required by the medical industry.