In the world of miniature machining, precision is key. Every operation, no matter how minute, carries the potential to affect the outcome of the final product. Front turning, a common operation in producing small parts, presents its own set of challenges. Whether it’s machining components for electronics, automotive, or medical industries, finding the right balance between speed, quality, and chip control is critical.

Two primary strategies are typically employed when it comes to front turning: multi-pass operations (light depth of cut and normal feed rate) and single-pass operations (large depth of cut and low feed rate). While both have their advantages, they also come with significant challenges. However, a new solution from NTK, called the Front Max (TFX), is changing the game by addressing many of these issues head-on.

The Dilemma of Multi-Pass vs. Single-Pass Machining

Multi-pass machining is often chosen for its conservative approach. By taking lighter cuts at normal feed rates, operators aim to maintain control over chip formation and surface finish. However, this method often results in longer cycle times, reducing overall productivity. Additionally, seams can appear on the surface due to multiple passes, and there’s always the risk that chips might clog the guide bushing, especially in Swiss-type lathes.

On the other hand, single-pass machining aims to improve efficiency by removing more material in one go, using a larger depth of cut (DOC) and a slower feed rate. The upside of this strategy is clear: shorter cycle times and no seam lines. However, it brings challenges such as increased cutting forces, potential tool chatter, poor surface finish, and unpredictable chip control. As many machinists will attest, these drawbacks often make single-pass operations difficult to maintain without compromising quality.

NTK’s Solution: The Front Max (TFX)

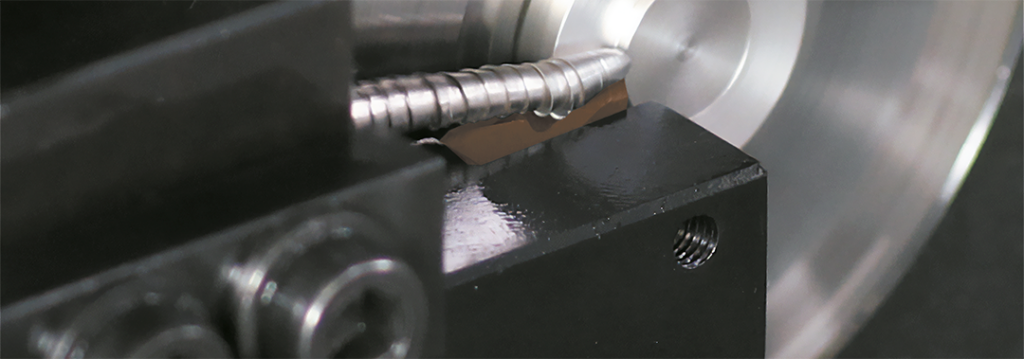

To tackle the shortcomings of single-pass machining, NTK has introduced the Front Max (TFX). This innovative cutting tool is specifically designed for large DOC operations and provides superior performance compared to traditional inserts. The TFX addresses key problems such as poor surface finish and inconsistent chip control by incorporating several unique features:

- Advanced Chipbreaker Design: The specially designed chipbreaker ensures excellent chip control in all cutting conditions, minimizing the risk of chips affecting the guide bushing or workpiece.

- High Rake Angle: By reducing cutting resistance, the high rake angle allows the tool to take deeper cuts while maintaining stability, which helps in preventing tool chatter and improving surface finish.

- Tangential Clamping System: This system provides high rigidity during large DOC operations, further enhancing the tool’s stability and contributing to a smoother surface finish.

- Wiper Inserts: TFX wiper inserts help to prevent chipping on the nose radius and are particularly effective in improving the surface finish, even in interrupted cuts.

The Front Max is available in NTK’s DM4 and ST4 Carbide grades. DM4 is ideal for stainless steels, as it reduces build-up edges and enhances machined surfaces. ST4 is a versatile choice across multiple material groups and excels in high-temperature machining due to its outstanding oxidation resistance

Benefits of Front Max in Single-Pass Operations

The TFX shines in single-pass operations where large DOC is required. It not only improves surface finish but also extends tool life and increases productivity. By reducing cycle time, the Front Max allows manufacturers to achieve better efficiency without sacrificing quality. The tool also handles difficult-to-machine materials such as stainless steel and high-temperature alloys, making it versatile across various industries

In a case study involving a spool valve, NTK’s TFX insert was compared to a traditional competitor insert in a single-pass operation. The result was significant: a reduction in cycle time from 18 seconds to just 6 seconds. Additionally, the TFX tripled tool life, further emphasizing its superiority in terms of cost savings and productivity.

Conclusion

As industries increasingly demand higher productivity and better surface quality, choosing the right machining strategy becomes crucial. While multi-pass operations offer control, their longer cycle times can hinder efficiency. Single-pass operations, though faster, often face quality and chip control challenges. NTK’s Front Max (TFX) solves these issues, offering superior chip control, enhanced rigidity, and optimized design for large DOC. By incorporating the Front Max, manufacturers can overcome the common challenges of front turning, achieving higher efficiency and improved results. It’s time to consider the benefits of NTK’s innovative solution.