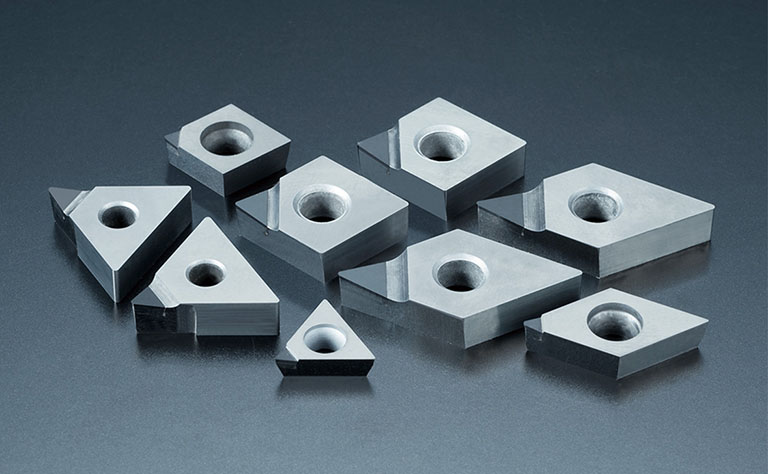

Non-ferrous material machining | Carbide grade for Swiss CNC lathes

Non-ferrous material machining | Carbide grade for Swiss CNC lathes

Tool cost advantages over PCD inserts

Perfect match for non-ferrous materials such as aluminum, brass, and plastics

Achieves excellent machined surface by suppressing the built-up edge

The overwhelming sharpness solves the problem of rough machined surface

Features

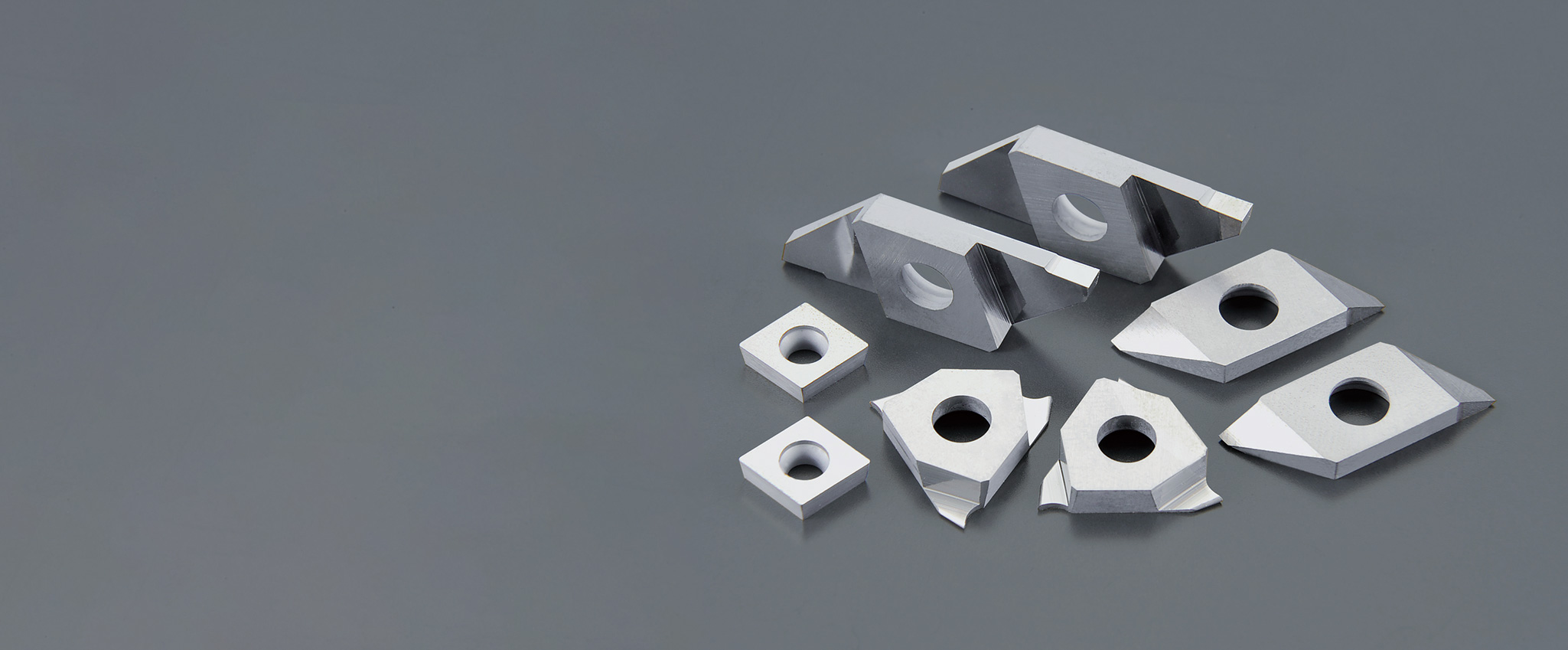

- Uncoated fine grain carbide precision ground and extremely sharp edge

- Polished mirror finish which eliminates built up edge

Stable workpiece dimensions and smooth machined surface

Tooling application

Non-ferrous materials such as aluminum, brass, copper, and plastics

Front turning / Back turning / Grooving / Cut off / Threading

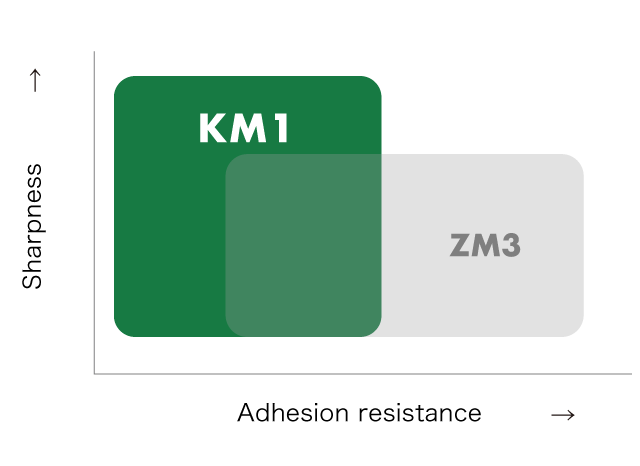

KM1 comparison chart

Up sharp edges and mirror finish

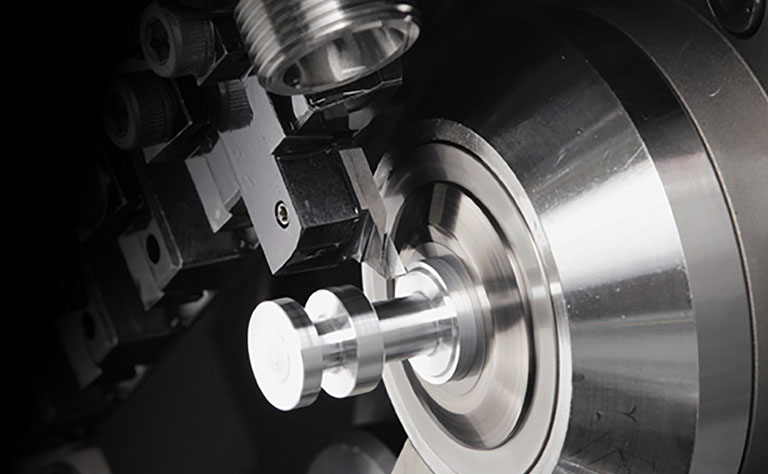

Case study

| Spool | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| KM1 | 300 pcs and more |

| Competitor’s PVD coated carbide | 200 pcs |

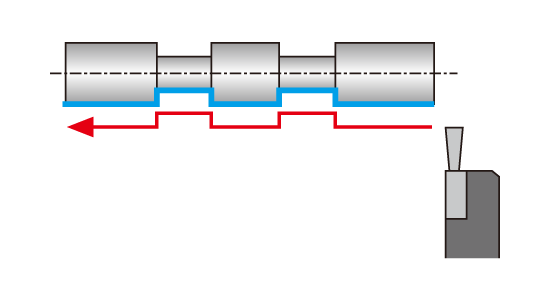

Competitor's product performed 3 rough grooving passes and 1 finishing pass but inserts were chipped and worn.

The total cycle time took over 3 minutes. KM1 performed operation in 1 pass with a cycle time of 1 minute and 50 seconds.

Tool lineup

Please check product catalog for tooling lineup

Other recommended products

-

GTPAMultifuntioning tool for machining non-ferrous material| Swiss CNC Lathes

Best tool for machining aluminum valve spool parts

-

PD1/PD2Non-ferrous material machining | PCD grades for Swiss CNC lathes

High speed, high efficiency machining

-

SPLASH seriesCoolant through toolholders | Swiss CNC Lathes

Extensive selection of styles and sizes

-

Y-axis holder seriesSelection for Front turning, back turning, grooving, Multi-functional groover (application-spool parts) | For Swiss CNC lathes (vertical gang style)

Uses gravity to direct chips downward away from part

Useful information

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining

The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining

Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining "Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab

"Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab