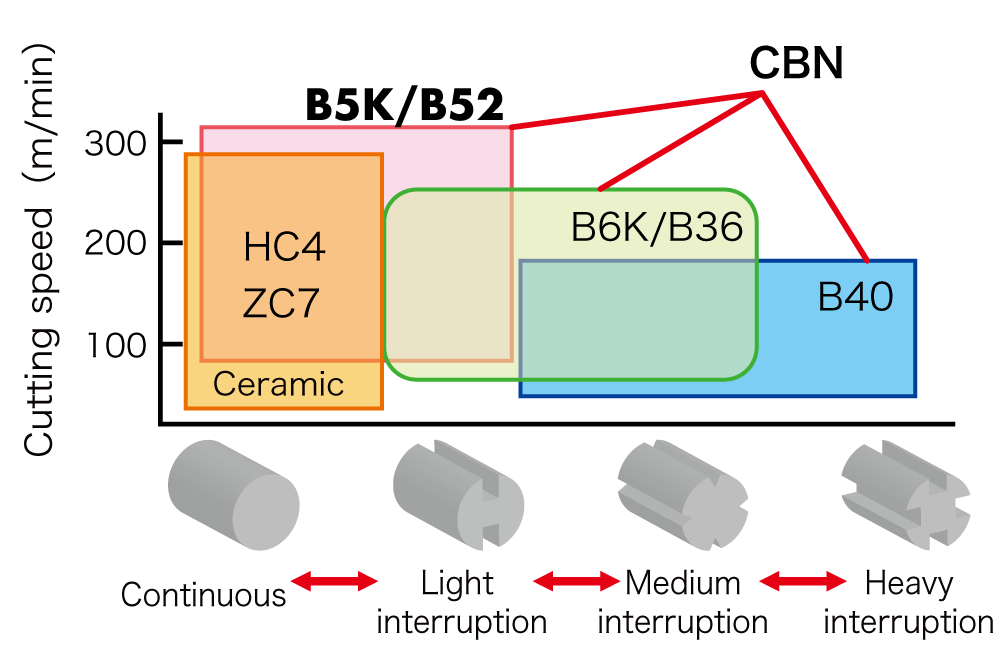

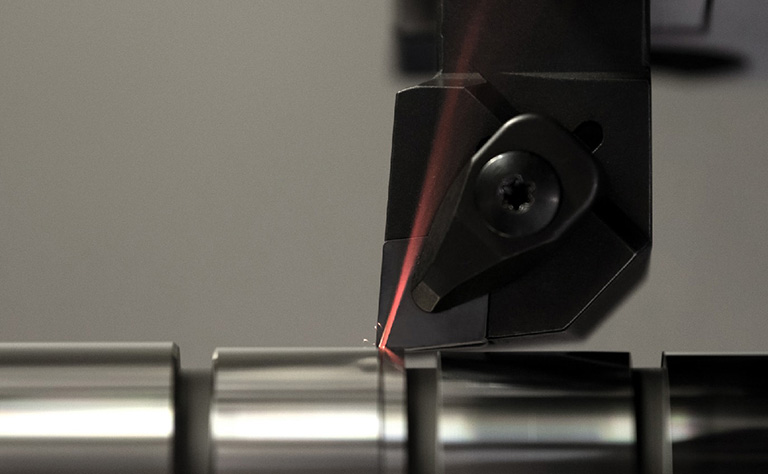

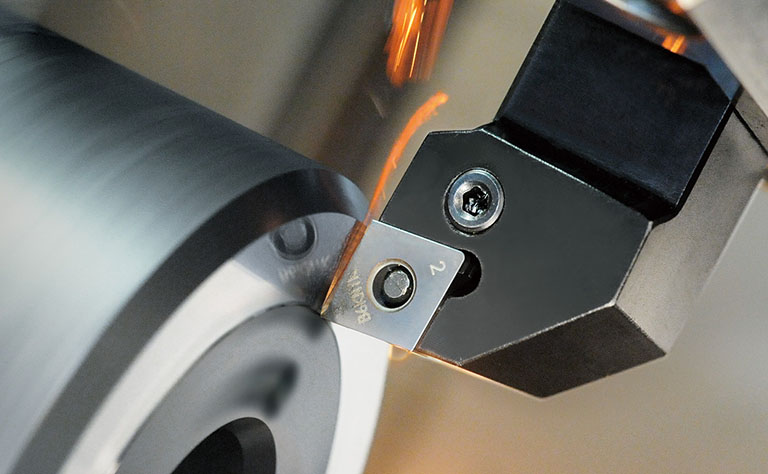

For continuous-light interruption machining | CBN for machining hardened material

For continuous-light interruption machining | CBN for machining hardened material

High performance, low cost, versatile CBN

CBN grades ideal for high-precision machining

Roughing to finishing continuous cut operations

Ideal for hardened materials of HRC 55 or higher

Product video

Features

- Excellent wear resistance due to optimum CBN content and special TiC binders

- Continuous to light interrupted machining

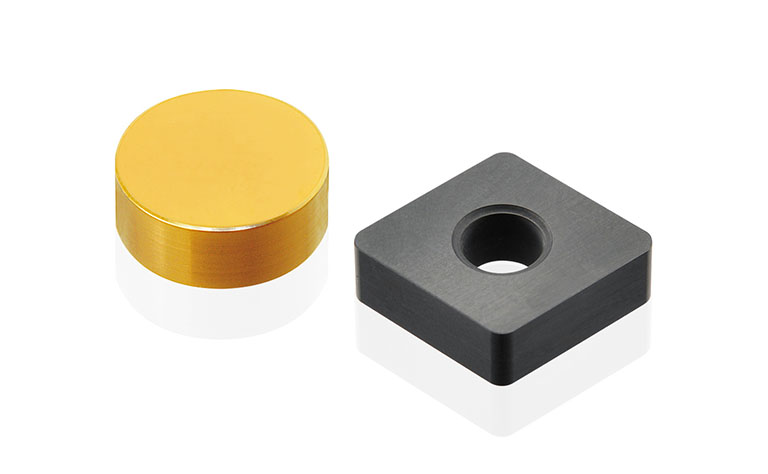

- B5K - coated CBN grade:

Ideal for machining the hardened material layer and the inner lower hardened layer. A special hard TiCN layer prevents a chemical reaction between the CBN and the iron in the work piece during material removal.

B52 - uncoated CBN grade:

Ideal for machining the hardened material layer.

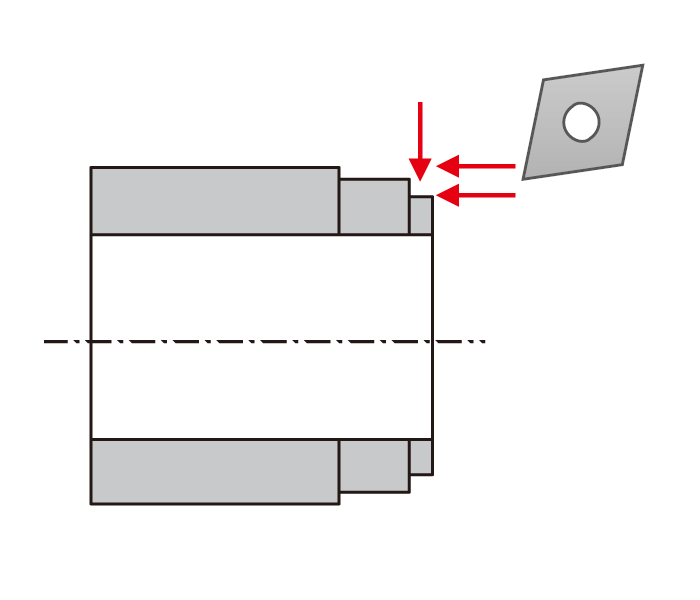

Tooling application

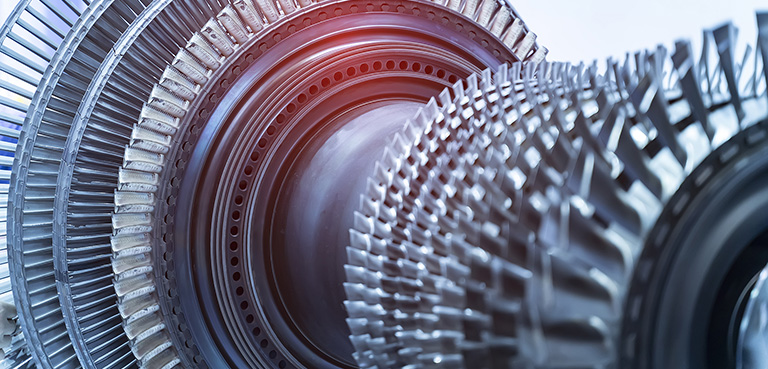

Continuous operations for hardened material at HRC55 or above

Grade application chart

Cutting conditions

Scroll the table →

| ●1st Recommendation 〇2nd Recommendation |

||||||||

| Grade | Material | Operation type | Machining | Cutting speed (m/min) | Feed(mm/rev) | DOC(mm) | DRY | WET |

|---|---|---|---|---|---|---|---|---|

| B5K/B52 | Hardened material (HRC55 or above) | Turning Continuous machining | Finishing | 100 - 300 | ~ 0.2 | 0.1 - 1.0 | 〇 | ● |

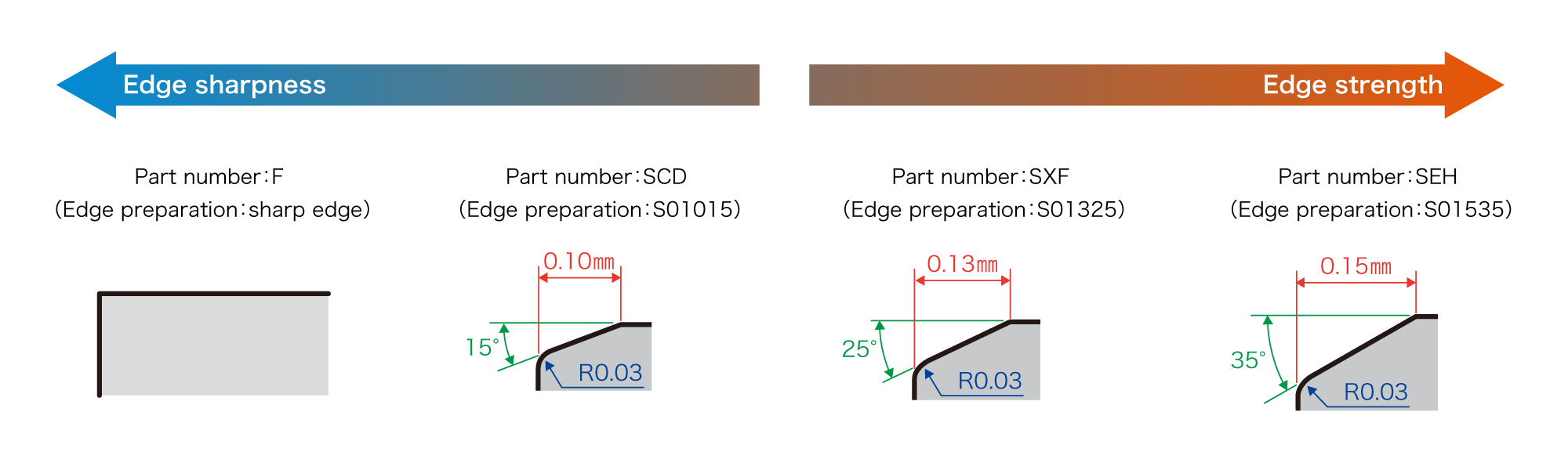

Edge preparations

Scroll the table →

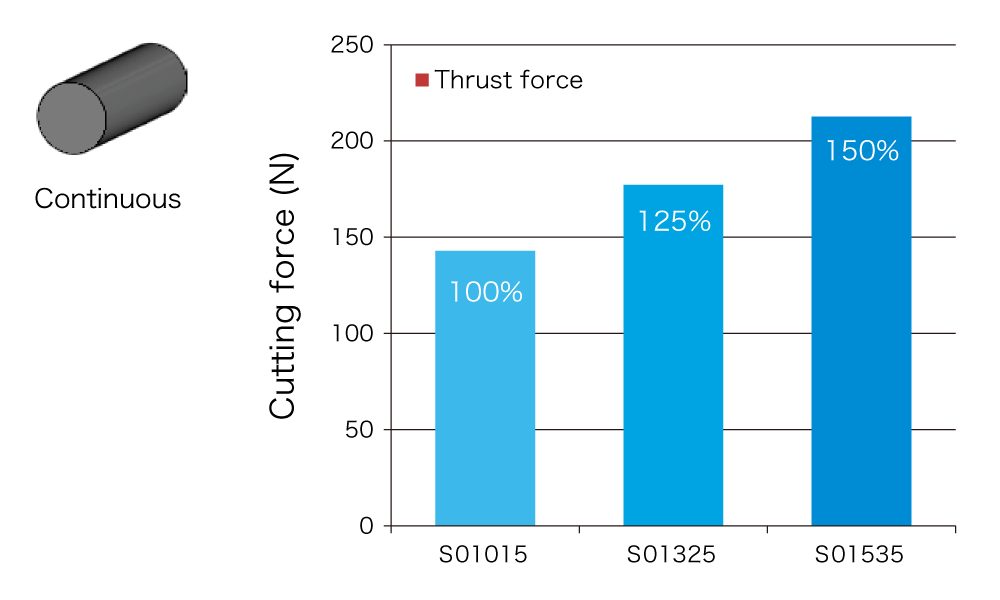

Performance comparison by edge preparation

- As the edge preparation increases the tool pressure on the insert increases.

- [ Cutting conditions ]

- SCM415(HRC63-65) vc=200m/min f=0.1mm/rev ap=0.2mm, DRY

- [ Insert ]

- TNGA160408

- There is a direct correlation between an increase in the edge preparation and improvement of insert fracture resistance.

- [ Cutting conditions ]

- SCM415(HRC63-65) vc=75m/min f=0.1mm/rev ap=0.3mm DRY

- [ Insert ]

- TNGA160408

Case study

| OD Turning of shaft parts | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| B5K | 6 pcs / corner |

|

| Competitor's coated CBN | 3 pcs / corner |

|

- B5K achieved 2 times longer tool life.

Due to dimensional changes and deterioration of the machined surface the competitor's coated CBN needed to be changed.

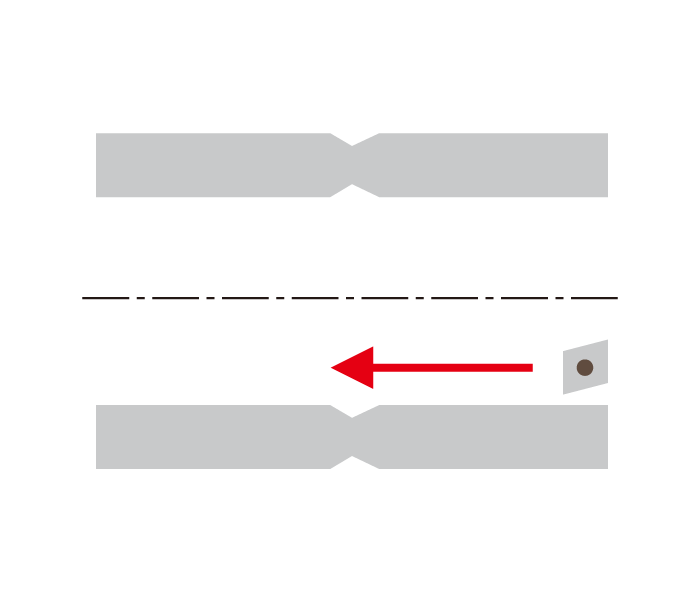

| ID boing of automotive parts | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| B52 | 240 pcs / corner |

|

| Competitor's coated CBN | 200 pcs / corner |

|

- B52 insert achieved 1.2 times higher tool life than the competitor's coated CBN insert.

Tool lineup

Please check product catalog for tooling lineup

Other recommended products

-

NTK450For continuous machining | NTK CeramiX

The ultimate ceramic grade for finishing hardened materials -" NTK CeramiX "

-

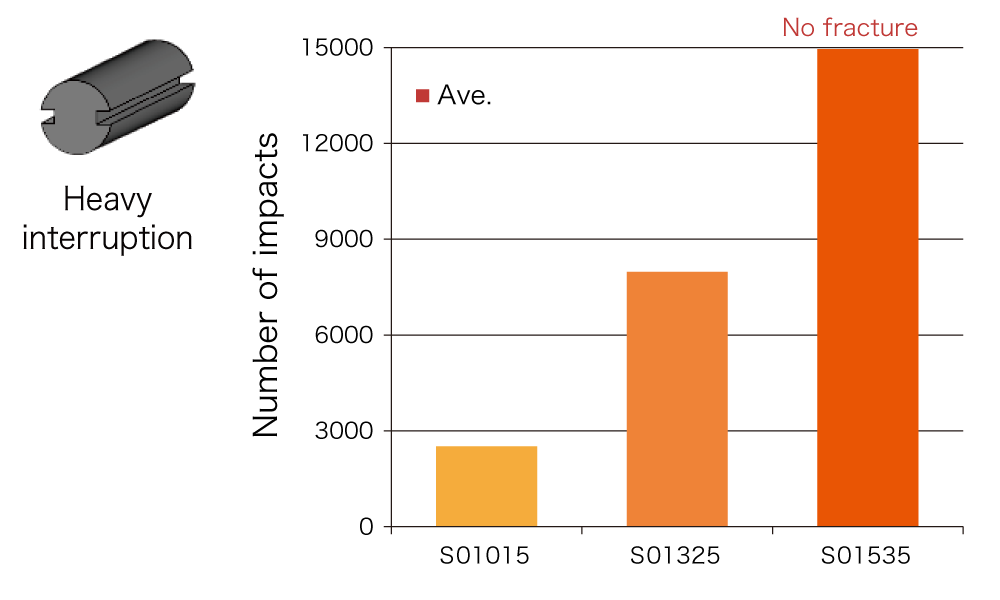

B6K/B36For light to medium interrupted machining | CBN for machining hardened material

High performance, low cost CBN

-

B40For heavy interrupted machining | CBN for machining hardened material

High performance, low cost CBN

-

ZC7/HC4For continuous machining | Ceramic for machining materials 30 - 70 HRC

Significant cost savings for high hardness materials

Useful information

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕 Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕 Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics

Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics How to Make Ceramic Cutting Tools from Scratch

How to Make Ceramic Cutting Tools from Scratch