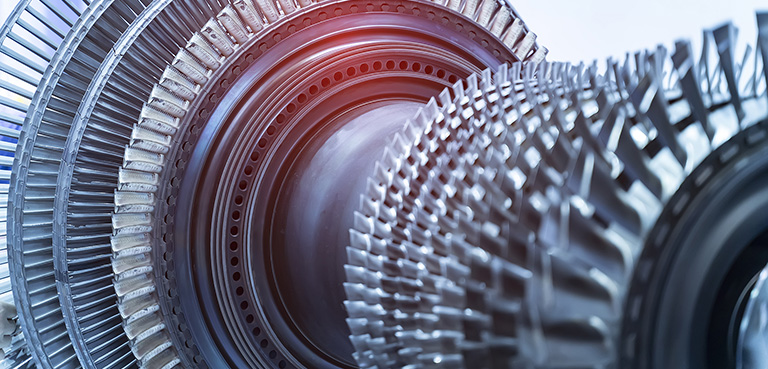

Metal additive manufacturing work processingRoughing with metal additive manufacturing work | Sialon ceramic

Grade for metal additive manufacturing workpiece processing

Achieving speedy rough cutting of metal additive manufacturing workpieces (nickel-based alloys)

Capable of high-speed machining about 10 times faster than carbide tools

Product machining video

Assumed machining work

Scroll the table →

Features

- Additively shaped nickel-based alloys can be machined with high efficiency

- Uses a ceramic material that emphasizes chipping resistance

Achieves high-speed and stable machining - Lineup of tools for milling and end milling

Tooling application

Additively manufactured workpieces using nickel-based alloys

Milling / End milling: roughing operations

Grade characteristics

Cutting conditions

Scroll the table →

| Grade | Material | Operation type | Machining | Cutting speed (m/min) | Feed (mm/t) | DOC (mm) | Coolant |

|---|---|---|---|---|---|---|---|

| SX3 / SX9 | Additive manufacturing workpiece (Nickel-based alloy) | Milling | Roughing | 450 - 1,000 | 0.07 - 0.12 | - | DRY |

| SX9 | End milling | 300 - 1,000 | 0.03 | - |

End milling

Milling

Workpiece comparison before and after cutting ①

Machining that takes about 8 minutes with a carbide tool can be shortened to about 1 minute with a ceramic tool.

Workpiece comparison before and after cutting ②

Achieves high-efficiency machining approximately 20 times that of carbide tools.

Tool lineup

Please check product catalog for tooling lineup

Other recommended products

-

JRF CutterFor machining heat-resistant alloys | Ceramic

NTK's newly designed small-diameter milling cutter for machining heat-resistant alloys

-

SX3Roughing & semi-finishing heat resistant alloys | Sialon ceramic

First recommendation for heat resistant alloys machining

-

SX7Roughing (no scale) to semi-finishing heat resistant alloys | Sialon ceramic

Wear resistant Sialon ceramic material

-

SX9Machines through scale on heat resistant alloys | Sialon ceramic

Excellent notch and flank wear resistant ceramic

Useful information

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕 Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕 Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics

Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics How to Make Ceramic Cutting Tools from Scratch

How to Make Ceramic Cutting Tools from Scratch