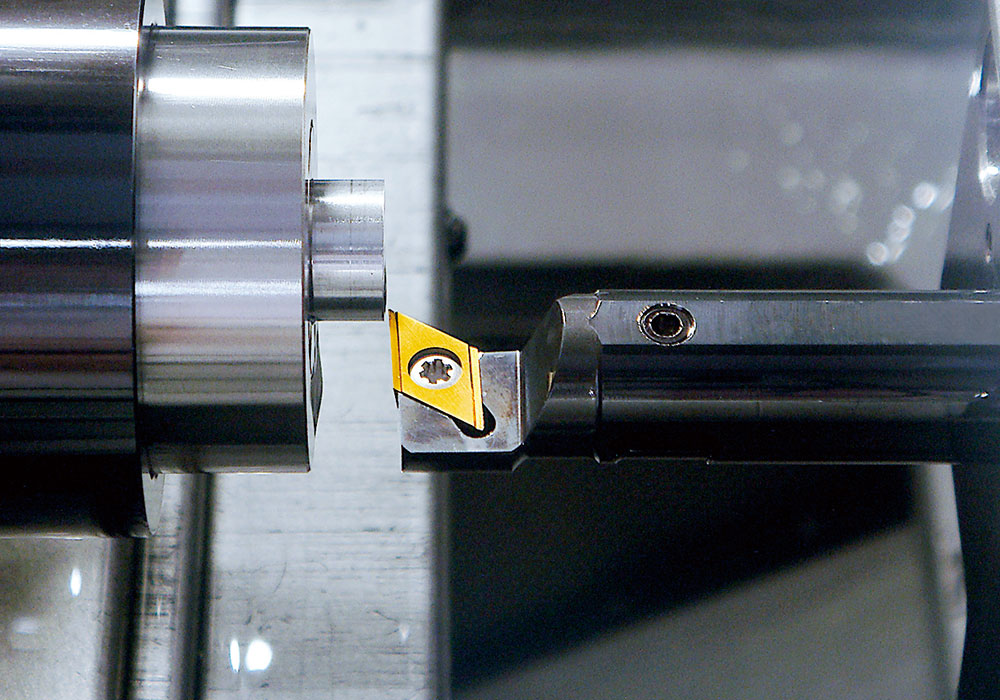

For front turning operations | Swiss CNC Lathes

For front turning operations

Capable of using Inverted toolholder

[ Cutting conditions ]

SUS304

304SS

Material :

SUS304

304SS

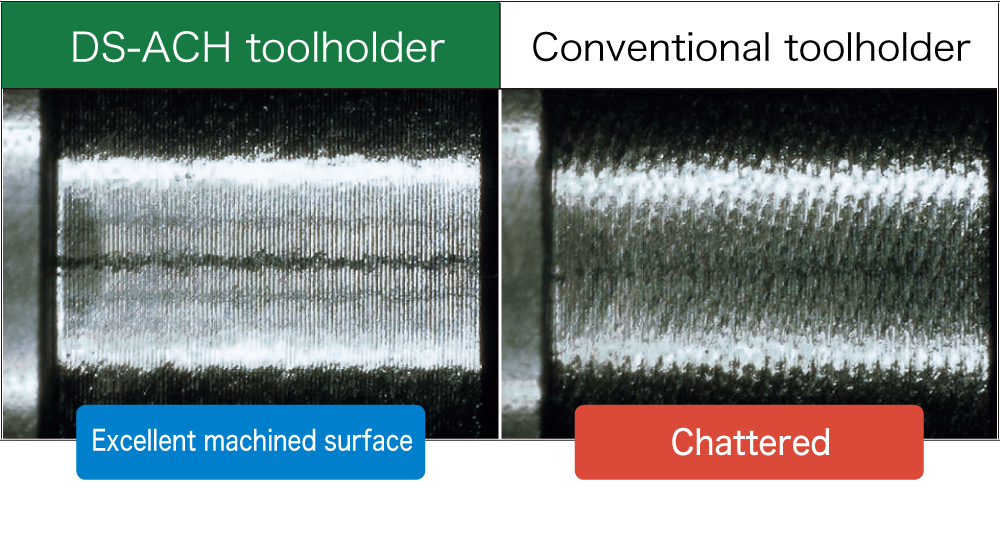

Holder : DS-SDUL19-11-ACH

Insert :

TM4 DCGT11T302MCL

DCGT32.508MCL TM4

Cutting conditions :

Vc = 75 m/min 、f = 0.05 mm/rev、ap = 2.0 mm

250 SFM .002 IPR .079” DOC

WET

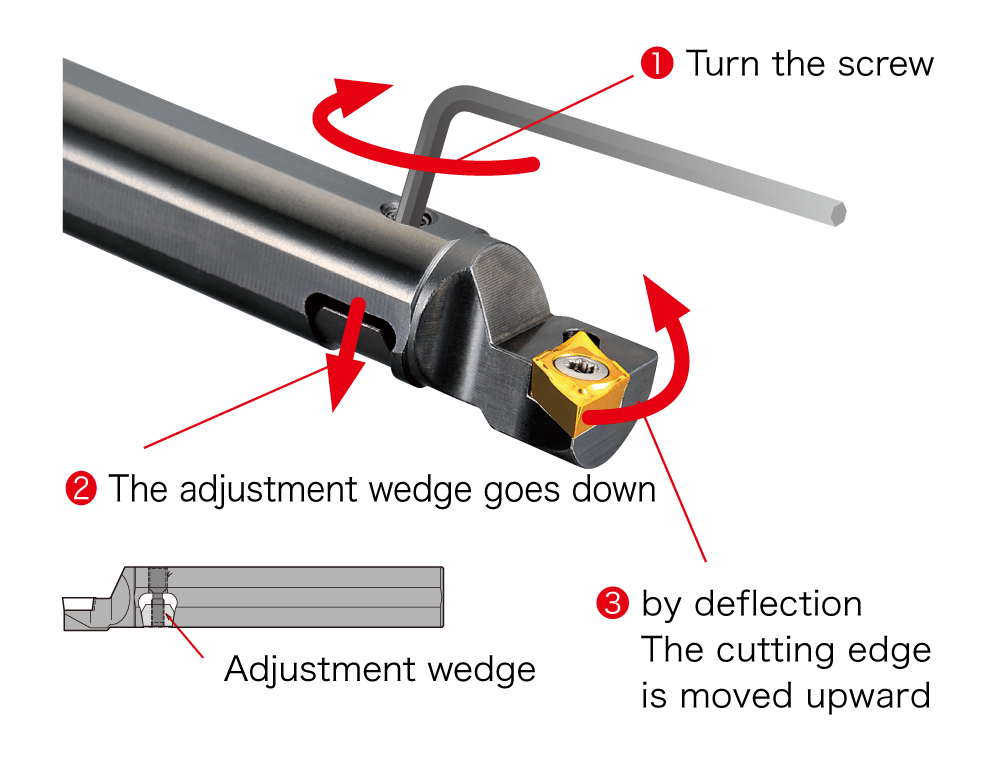

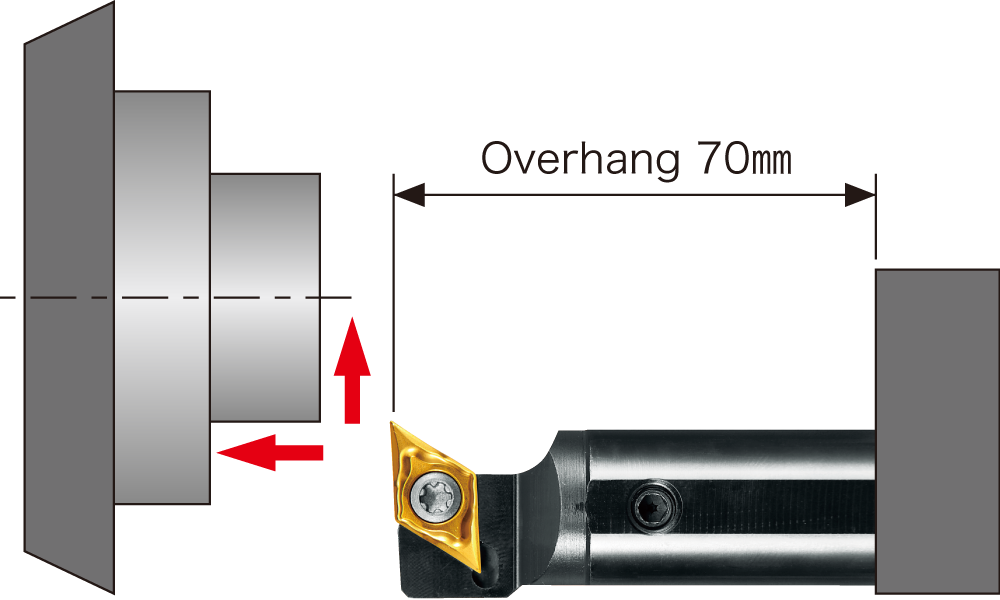

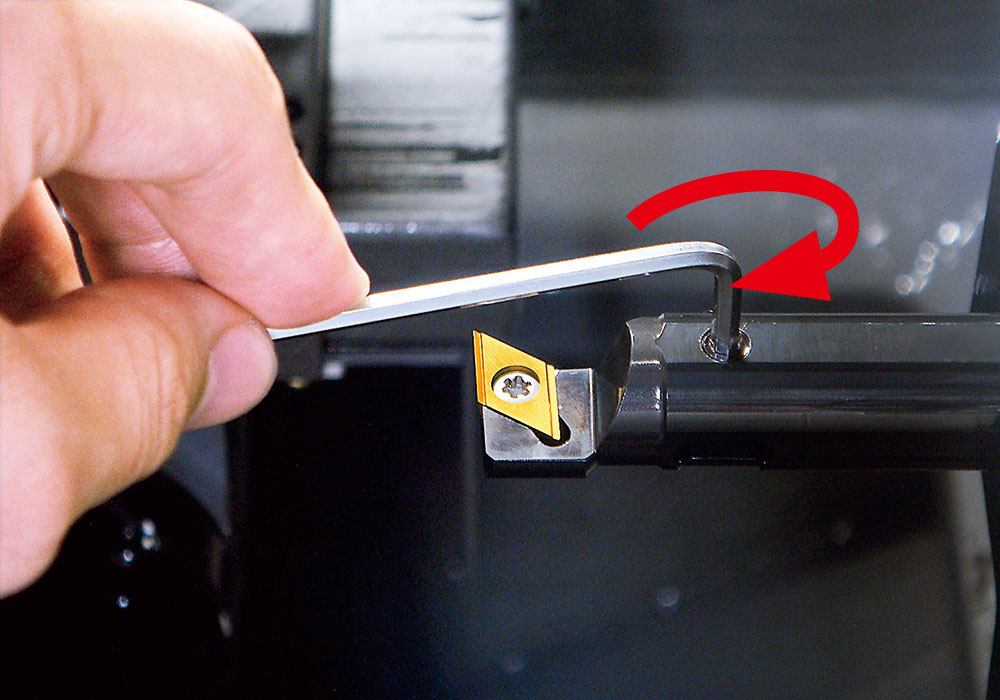

① Install the holder slightly below centerline.

Then take a facing test cut. (be sure to loosen the wedge screw)

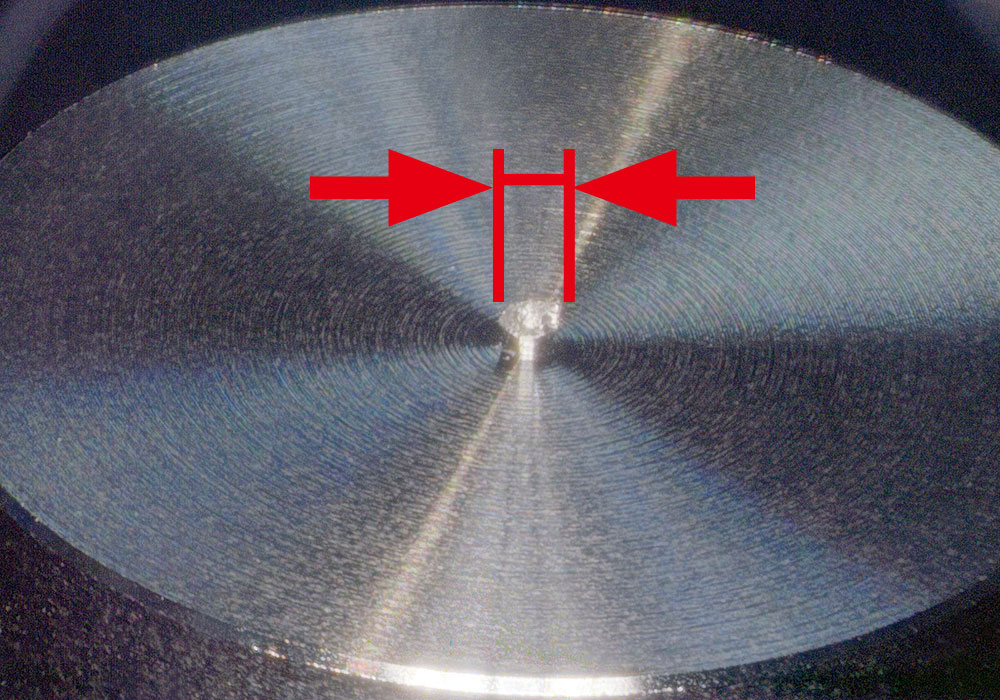

② Measure the diameter of the center boss.

③ Raise the center height by one half of the diameter of the boss.

Adjustment instruction sheet is supplied in the toolholder case.

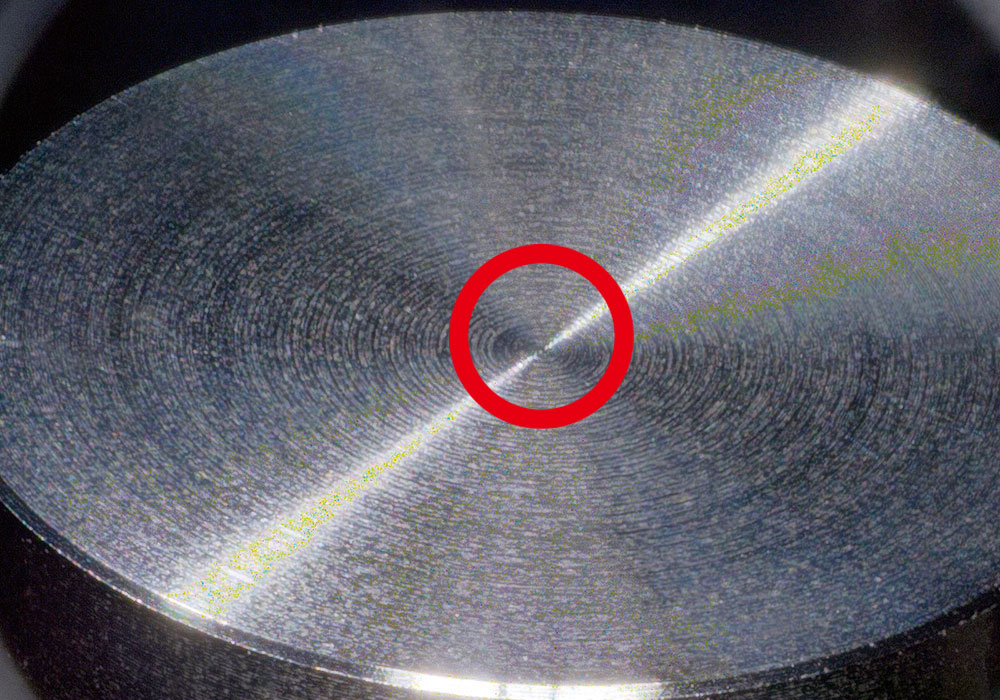

④ Re-machine the end face.

For more information about this product, visit our online e-catalog, or download the catalog/product report

Other recommend products