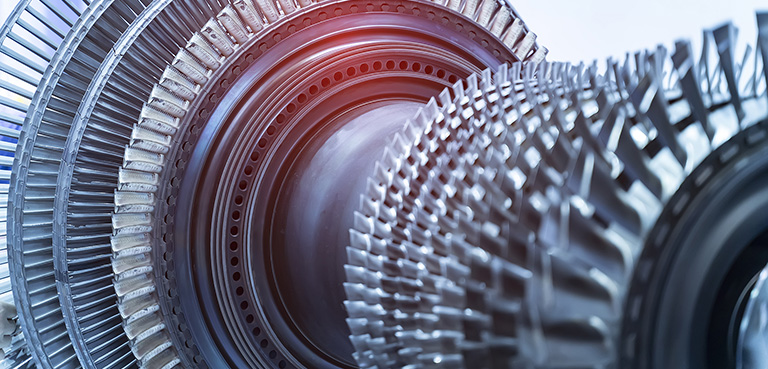

CutterFor machining heat-resistant alloys | Ceramic

CutterFor machining heat-resistant alloys | Ceramic

NTK's newly designed small-diameter milling cutter

for machining heat-resistant alloys

New innovation in small-diameter milling cutters for ceramic inserts

3 negative inserts on φ16 cutter body.

The negative insert, which can be used on both sides and has high cutting edge strength, and the high efficiency of the 3-flute insert contribute to reduced tool cost, stable machining, and improved productivity.

Features

- Higher number of inserts for even higher efficiency

- Negative inserts with higher cutting edge strength for more stable machining

- Economical negative insert that can be used on both sides

Tooling application

Milling

For Aerospace, Power Generation

Higher number of inserts for even higher efficiency

3 negative inserts on φ16 cutter body

Increased clamping force prevents insert rotation during machining

New clamp system (φ16)

Parts installation procedure video

Economical negative insert that can be used on both sides

Increased clamping force prevents insert rotation during machining

🟡 Available corners

Negative inserts with higher cutting edge strength for more stable machining

| Cutter body dia.: φ16 (Bottom machining Dia.: φ9.65) | |

| Work material | Inconel718 |

| Cutting speed (m/min) | 606(20000rpm) |

| Feed( mm/t) | 0.1 |

| DOC (mm) | 1.0 |

| Removal volume per tooth (cc) | 16.66 |

※Since the new NTK cutter has three inserts, the total volume removed is 1.5 times that of competitor's.

Life extension breaker

A step breaker with the cutting edge lowered from the clamping surface suppresses flaking.

Recommended Cutting conditions

Scroll the table →

| Grade | Material | Operation type | Cutting speed (m/min) | Feed (mm/t) | DOC (mm) | Coolant |

|---|---|---|---|---|---|---|

| SX3 / SX9 | Heat resistant alloys | Milling | 400 - 700 ‒ 1000 | 0.08 - 0.10 - 0.12 | - 1.0 | DRY |

Allowable rotation speed

| Cutter Item number | Cutting edge dia | Tooth | Allowable rotation speed (min-1) |

|---|---|---|---|

| JRFMH016E160R03 | 16 | 3 | 20,000 |

| JRFIH0625E0625R03 | 15.875 | ||

| JRFMH020E200R03 | 20 | 17,500 | |

| JRFIH075E075R03 | 19.05 | ||

| JRFMH025E250R04 | 25 | 4 | 15,000 |

| JRFIH100E100R04 | 25.4 | ||

| JRFMH032E320R05 | 32 | 5 | 15,000 |

| JRFIH125E125R05 | 31.75 | ||

| JRFMH025E250R03 | 25 | 3 | 12,500 |

| JRFIH100E100R03 | 25.4 | ||

| JRFMH032E320R04 | 32 | 4 | 12,500 |

| JRFIH125E125R04 | 31.75 | ||

| JRFMH032E320R03 | 32 | 3 | 12,500 |

| JRFIH125E125R03 | 31.75 |

Case study

| Waspaloy(Combustion case) | ||

|---|---|---|

| JRF Cutter | Competitor's | |

| Grade | SX9 | SX9 (RP) |

| Tooth | 5 (Φ32) | 3 (Φ32) |

| Vc (m/min) | 564 | 564 |

| Fz (mm/t) | 0.05 | 0.05 |

| F (mm/min) | 2000 | 1200 |

| DOC ap (mm) | 1.0 | 1.0 |

| Tool life | 2 Pass | 1 Pass |

| Corner | 8 | 5 |

|

|

| Cost Productivity | |

| NTK | 68% ← |

|---|---|

| Competitor's | 100% |

32% cost reduction!

Insert unit price ÷ Number of corners used (life) x Number of teeth

Lineup

Scroll the table →

| Cutter Item number | Cutting edge dia | Tooth | Insert Item number | IC | Thickness | Cap screw | Wedge screw | Wrench (sold separately) |

|---|---|---|---|---|---|---|---|---|

| JRFMH016E160R03 | 16 | 3 | -SX3RNGF060300E-HNF -SX9RNGF060300E-HNF |

6.35 | 3.18 | HCS3P050 | HWS3P050 | DL-025-08-JRF |

| JRFIH0625E0625R03 | 15.875 | |||||||

| JRFMH020E200R03 | 20 | -SX3RNGF060400E-HNF -SX9RNGF060400E-HNF |

4.76 | |||||

| JRFIH075E075R03 | 19.05 | |||||||

| JRFMH025E250R04 | 25 | 4 | DL-025-20-JRF | |||||

| JRFIH100E100R04 | 25.4 | |||||||

| JRFMH032E320R05 | 32 | 5 | -SX3RNGF090400E-HNF -SX9RNGF090400E-HNF |

9.525 | ||||

| JRFIH125E125R05 | 31.75 | |||||||

| JRFMH025E250R03 | 25 | 3 | HCS5P080 | HWS5P080 | DL-040-20-JRF | |||

| JRFIH100E100R03 | 25.4 | |||||||

| JRFMH032E320R04 | 32 | 4 | ||||||

| JRFIH125E125R04 | 31.75 | |||||||

| JRFMH032E320R03 | 32 | 3 | -SX3RNGF120400E-HNF | 12.7 | ||||

| JRFIH125E125R03 | 31.75 |

Product video

Catalog

Contact

Other recommended products

-

SX3Roughing & semi-finishing heat resistant alloys | Sialon ceramic

First recommendation for heat resistant alloys machining

-

SX9Machines through scale on heat resistant alloys | Sialon ceramic

Excellent notch and flank wear resistant ceramic

-

SX5Machine heavy scale & interruptions on heat resistant alloys| Sialon ceramic

Toughest SiAlON ceramic on the market

-

SX7Roughing (no scale) to semi-finishing heat resistant alloys | Sialon ceramic

Wear resistant Sialon ceramic material

Useful information

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕 Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕 Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics

Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics How to Make Ceramic Cutting Tools from Scratch

How to Make Ceramic Cutting Tools from Scratch