[ Made to order ]Machine heavy scale & interruptions on heat resistant alloys| Sialon ceramic

[ Made to order ]Machine heavy scale & interruptions on heat resistant alloys| Sialon ceramic

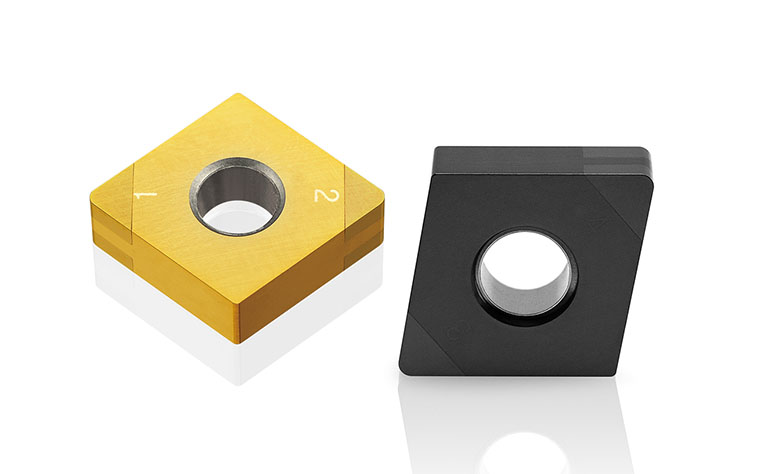

Toughest SiAlON ceramic on the market

First recommendation for machining through scale

Excellent notch wear resistance ideal for machining scale

Features

- Ceramic with the highest fracture resistance

- Best for machining where scale or interruptions exist

- Best grade for roughing Waspaloy with scale

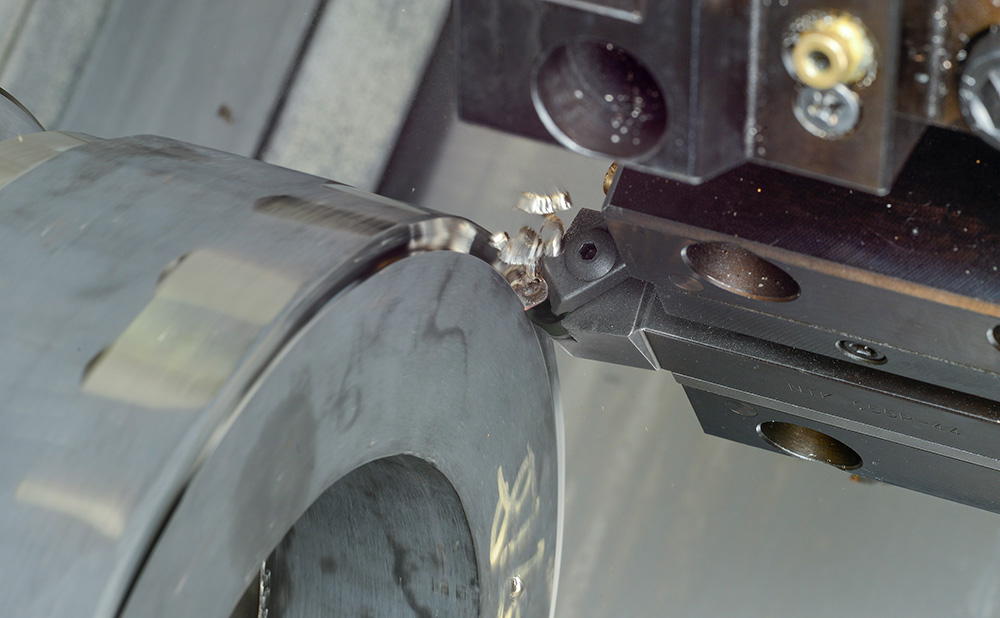

Tooling application

Finishing Heat resistant alloys

Turning / grooving through scale

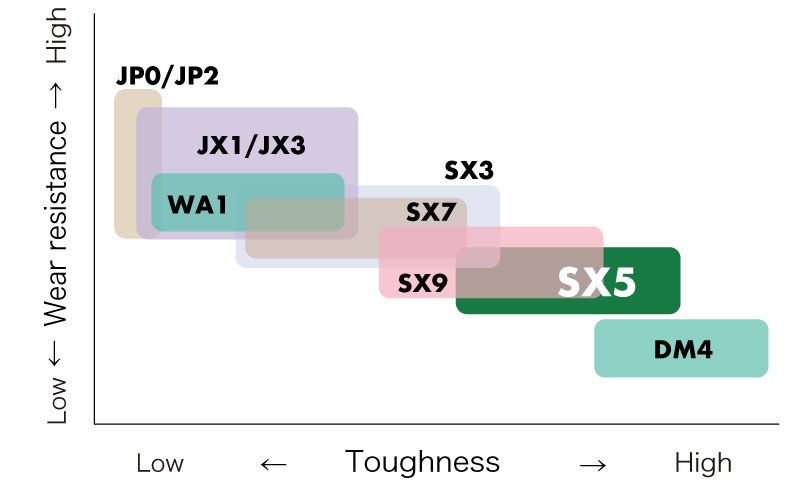

Grade characteristics

Cutting conditions

Scroll the table →

| Grade | Material | Operation type | Machining | Cutting speed (m/min) | Feed(mm/rev) | DOC(mm) | Coolant |

|---|---|---|---|---|---|---|---|

| SX5 | Heat resistant alloys | Turning | Roughing with scale | 180 - 240 | 0.2 - 0.35 | 1.0 - 5.0 | WET |

| Grooving | 0.07 - 0.17 | - |

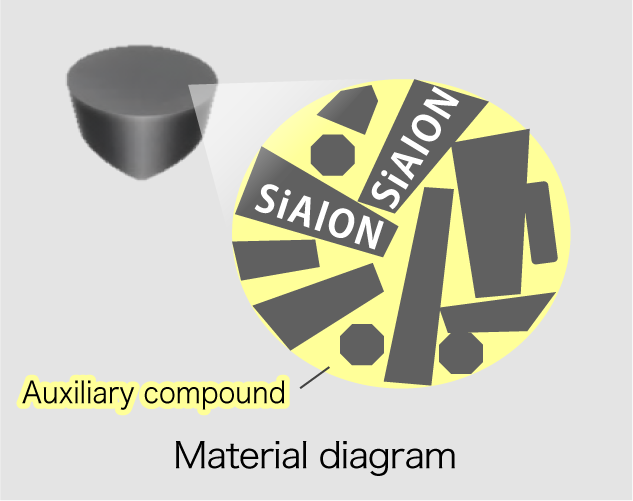

Why are Sialon ceramics so effective at high-speed machining of heat resistant alloys?

Silicon nitride (Si3N4) is combined with Aluminum (Al) and oxygen (O) to make SiAlON.

Sialon has needle-shaped particles similar to that of Silicon nitride.

The arrangement of these particles makes the material withstand the impact force during cutting.

The addition of the alumina improves its heat resistance characteristics.

The property advantages makes it perfect for machining heat resistant alloys.

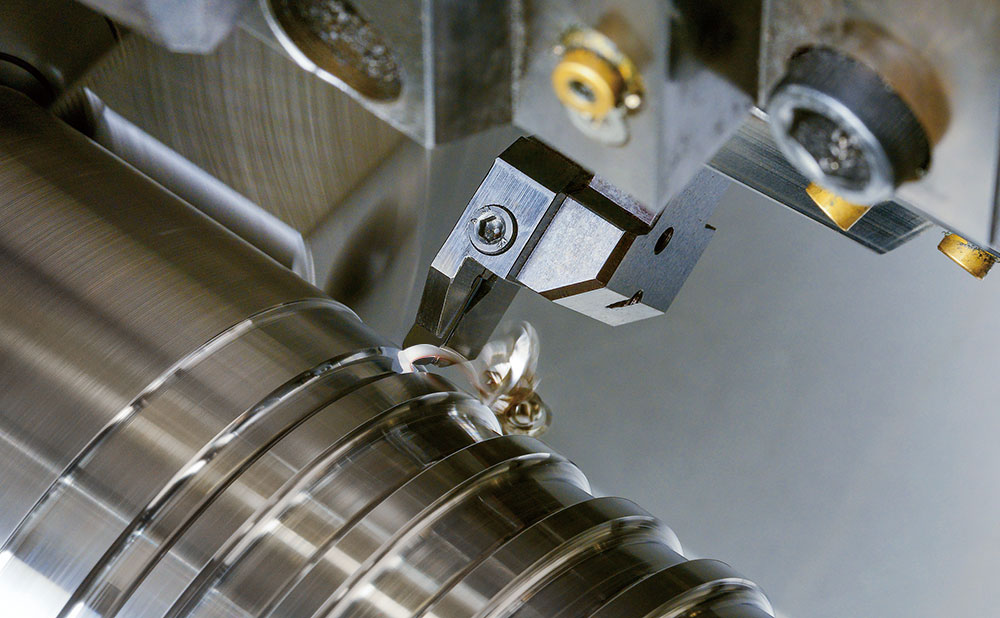

Machining Inconel with scale

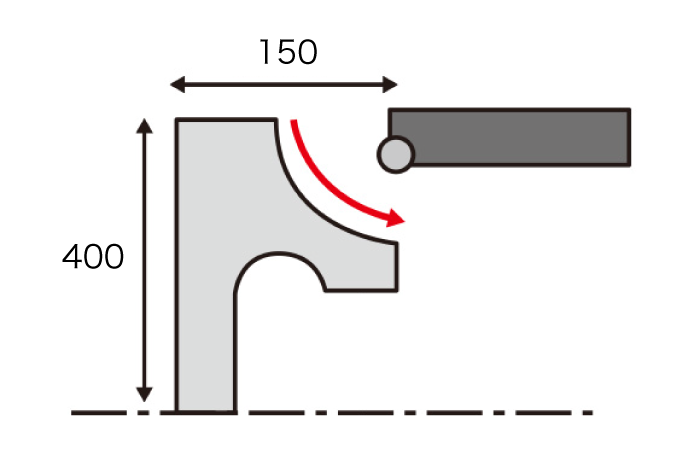

Grooving Inconel

Case study

| Ring (Roughing with scale) | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| SX5 | 1 pass |

| Current tool (competitor's whisker) |

1 pass |

- High feed rate is possible because of SX5's toughness.

It achieved 2.5 times more efficient results compared to the competitor's whisker.

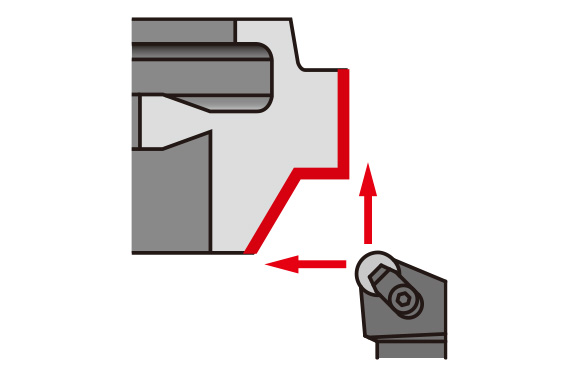

| Aircraft part (Roughing with scale) | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| SX5 | 1 pass |

| Current tool (competitor's Sialon ceramic) |

1 pass Chipping |

- SX5 insert had more stable performance and no edge chipping compared to the competitor's Sialon grade.

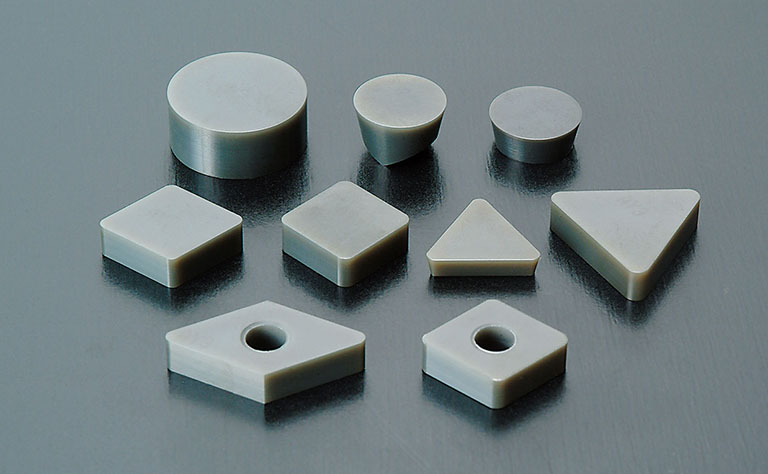

Tool lineup

Other recommended products

-

JX1/JX3Roughing to semi-finishing of heat resistant alloys | BIDEMICS

Revolutionary material for machining heat resistant alloys

-

NTK120/JP2Finishing Heat resistant alloys | BIDEMICS

Machine HRSA materials at speeds of Vc=500 m/min with BIDEMICS

-

SX3Roughing & semi-finishing heat resistant alloys | Sialon ceramic

First recommendation for heat resistant alloys machining

-

SX9Machines through scale on heat resistant alloys | Sialon ceramic

Excellent notch and flank wear resistant ceramic

Useful information

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕 Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕 Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics

Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics How to Make Ceramic Cutting Tools from Scratch

How to Make Ceramic Cutting Tools from Scratch