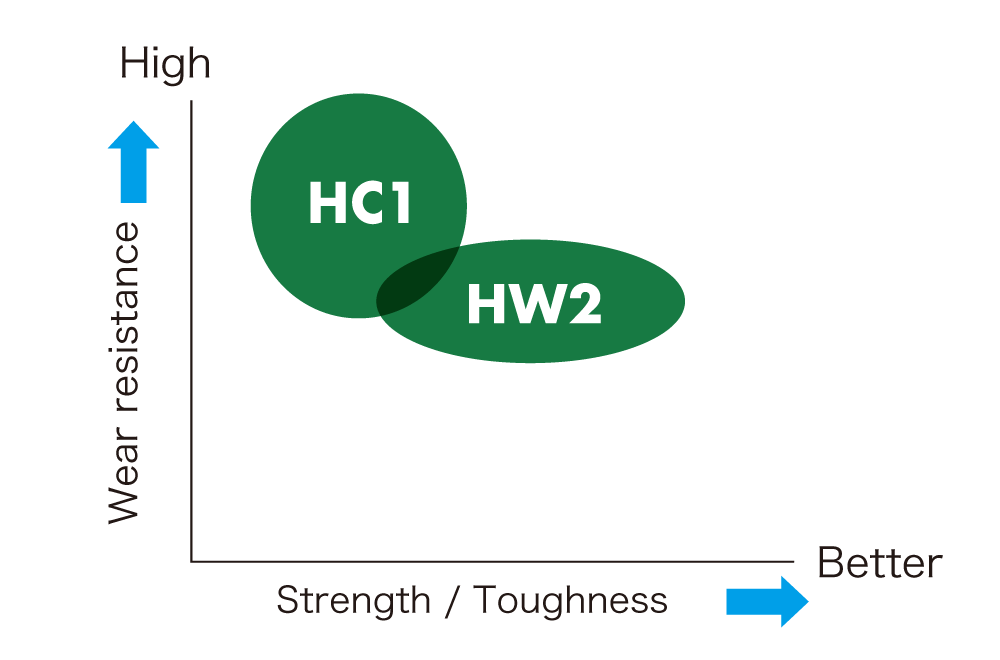

Mecanizado continuo de fundición gris| Cerámica de alúmina (cerámica blanca)

Gray cast iron

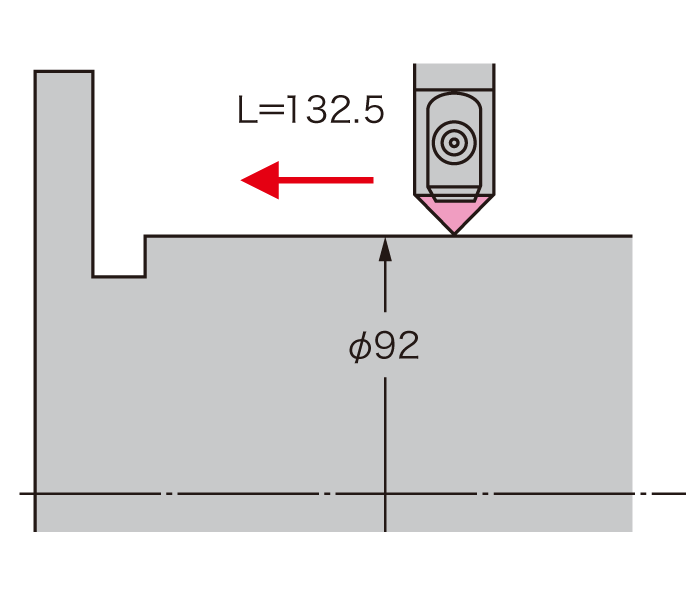

Finish Turning

| Grade | Material | Operation type | Machining | Cutting speed (m/min) Cutting speed (SFM) | Feed(mm/rev) Feed(IPR) | DOC(mm) DOC(inch) | Coolant |

|---|---|---|---|---|---|---|---|

| HC1 | Gray cast iron | Turning | Finish turning of Gray cast iron | 350 – 700 1200 -2300 | 0.1 – 0.4 .004 – .016 | -2.0 – .080 | DRY |

| HW2 | Roughing to semi-interrupted finishing of gray cast Roughing to finishing of cylinder liners | 350 – 600 1200 – 2100 |

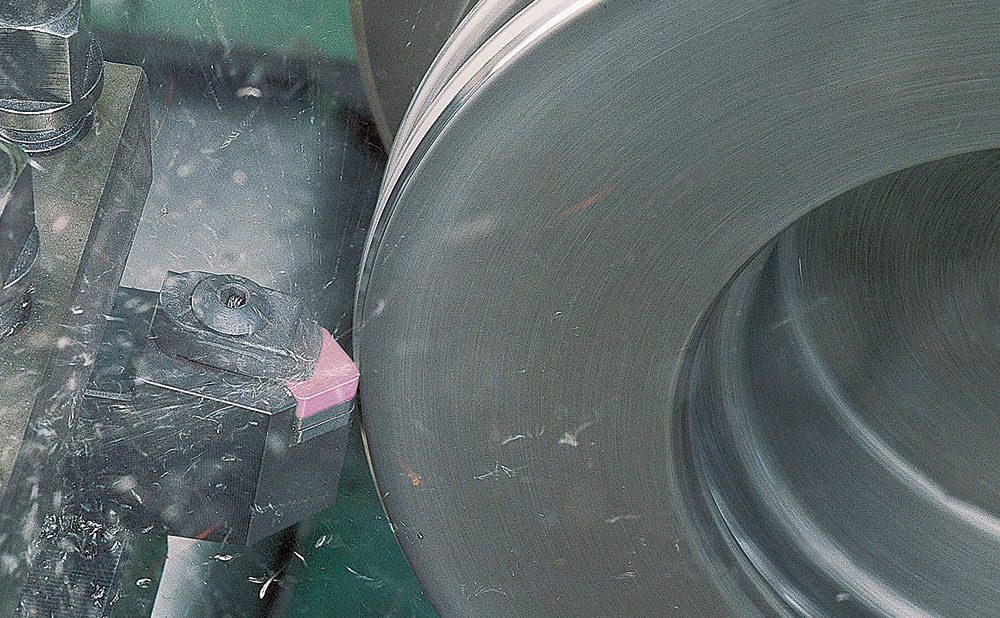

| Disk brake | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| HC1 |

130 pcs / corner

|

|

| Competitor’s black ceramic |

60 pcs / corner

|

|

HC1 doubled the tool life of the competitor’s black ceramic.

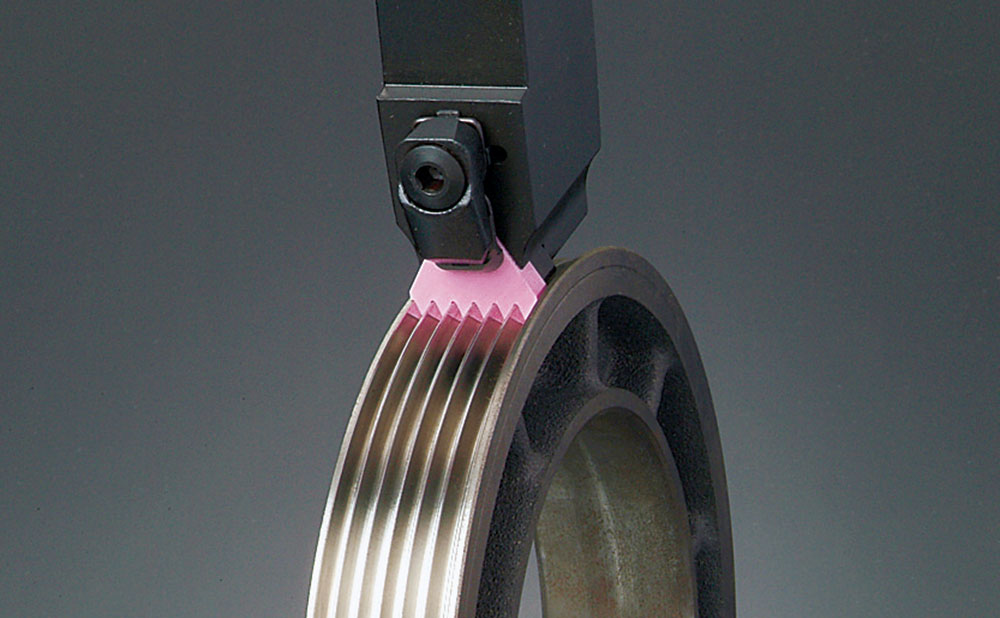

| Cylinder liner | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| HW2 |

70 pcs / corner

|

|

| Competitor’s ceramic |

30 pcs / corner

|

|

HW2 doubled the tool life and achieved superior surface finishes on the part compared to the competitor’s insert.

For more information about this product, visit our online e-catalog, or download the catalog/product report