Polygon Taper Type | Quick-change tool series for automatic lathes

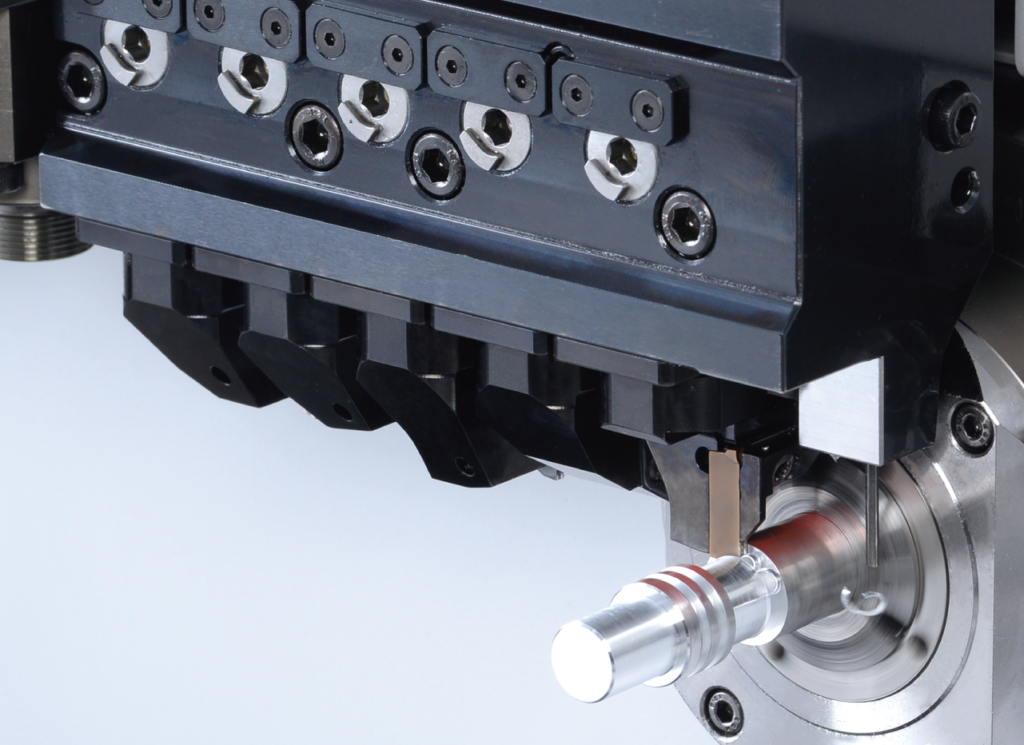

Front turning / Back turning / Grooving / Threading / Cut off

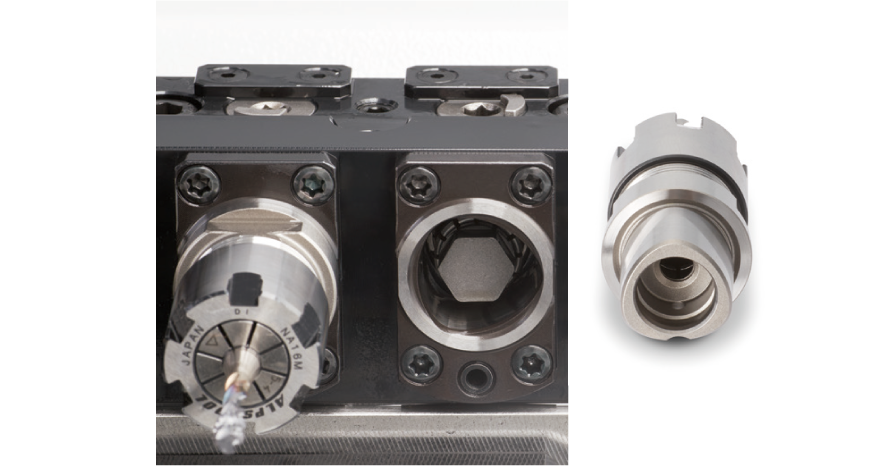

AQ2size Dedicated tool post

Time Reduction

The unique coupling structure allows for quick tool changes with just a half-turn of the wrench. Reduces setup time by approx. 80%, ensuring reliable tool changes.

Repeatability

The dual-contact clamp unit with polygon taper shank provides strong clamping force and ensure ±2um repeatability.

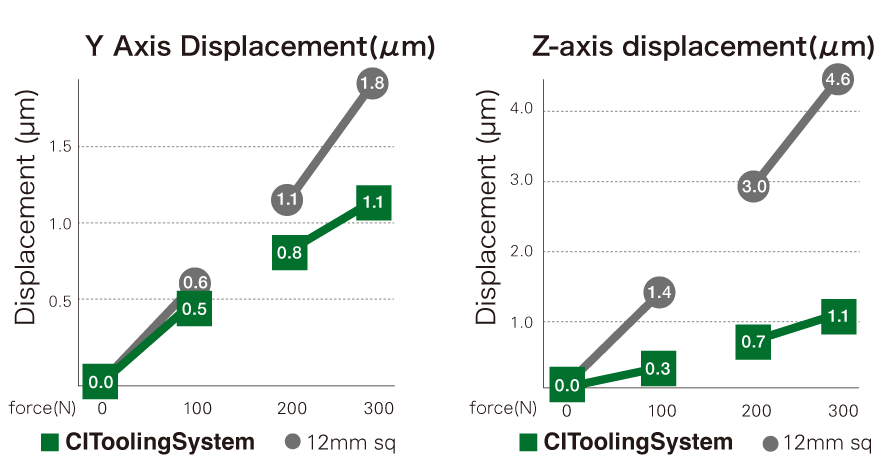

High Rigidity

Ensures high rigidity with a size equivalent to a 12mm .4720” square shank toolholder. Contributes to chatter suppression under high load, Toollife extension, and stable workpiece quality.

For more information about this product, visit our online e-catalog, or download the catalog/product report