For continuous machining | Ceramic for machining materials 30 - 70 HRC

For continuous machining | Ceramic for machining materials 30 - 70 HRC

Significant cost savings for high hardness materials

Machines a wide range of hardened materials

Real tool cost reductions by replacing CBN

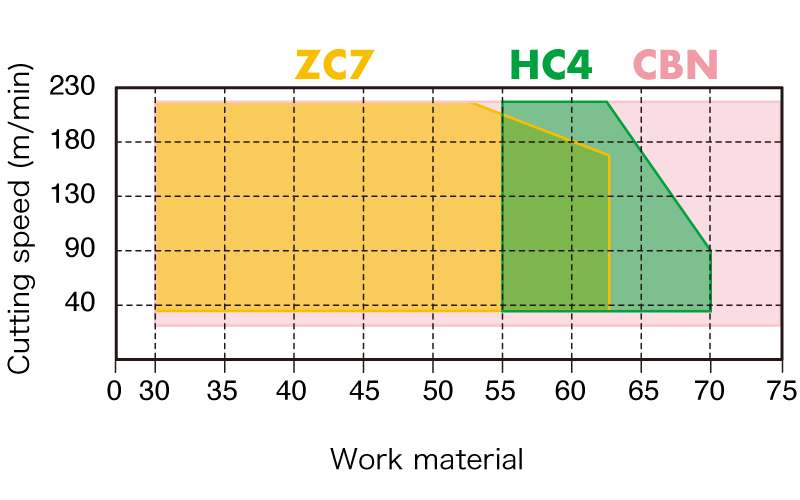

ZC7: Ideal for hardened materials from 30 - 62 HRC

HC4: Ideal for hardened materials from 55 - 70 HRC

Features

- High hot hardness and low plasticity at high temperature ranges make them ideal for finishing of hardened materials

- Significant tool cost reductions are achieved by replacing CBN

- Inserts with a wiper flat or a chipbreaker are available to further improve machining efficiency

- ZC7 excellent for machining carburized or induction hardened steels.

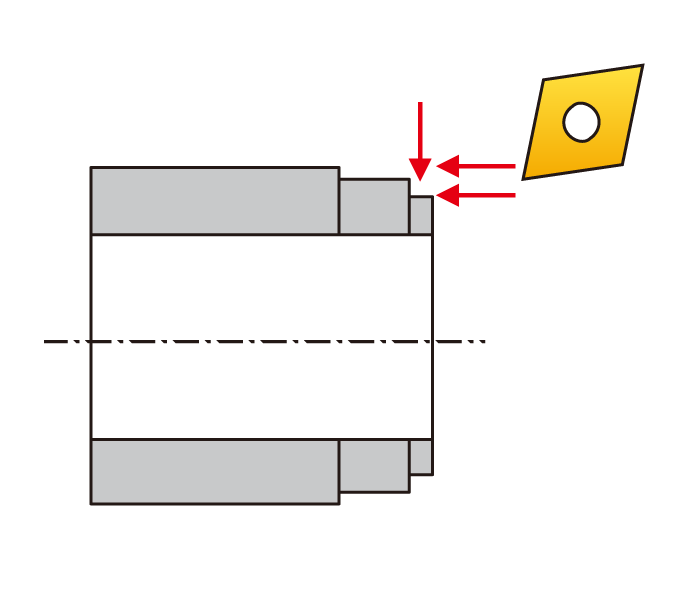

Tooling application

Hardened material

Continuous finish turning hardened materials 30-70HRC

Grade & Speed recommendation chart

Cutting conditions

Scroll the table →

| Grade | Material | Operation type | Machining | Cutting speed (m/min) | Feed(mm/rev) | DOC(mm) | DRY | WET |

|---|---|---|---|---|---|---|---|---|

| ZC7 | Hardened material (HRC30-62) | Turning Continuous machining |

Finishing | 40 - 200 | - | - | - | ● |

| HC4 | Hardened material (HRC55-70) |

Recommended Depth of cut and Feed rate

| Corner R | DOC (㎜) | Feed (㎜ /rev) |

|---|---|---|

| R0.4 | 0.15 | 0.05 ~ 0.08 |

| R0.8 | 0.3 | 0.08 ~ 0.10 |

| R1.2 | 0.4 | 0.10 ~ 0.13 |

| R1.6 | 0.5 | 0.13 ~ 0.16 |

| Round insert | 2.0 | 0.16 ~ 0.25 |

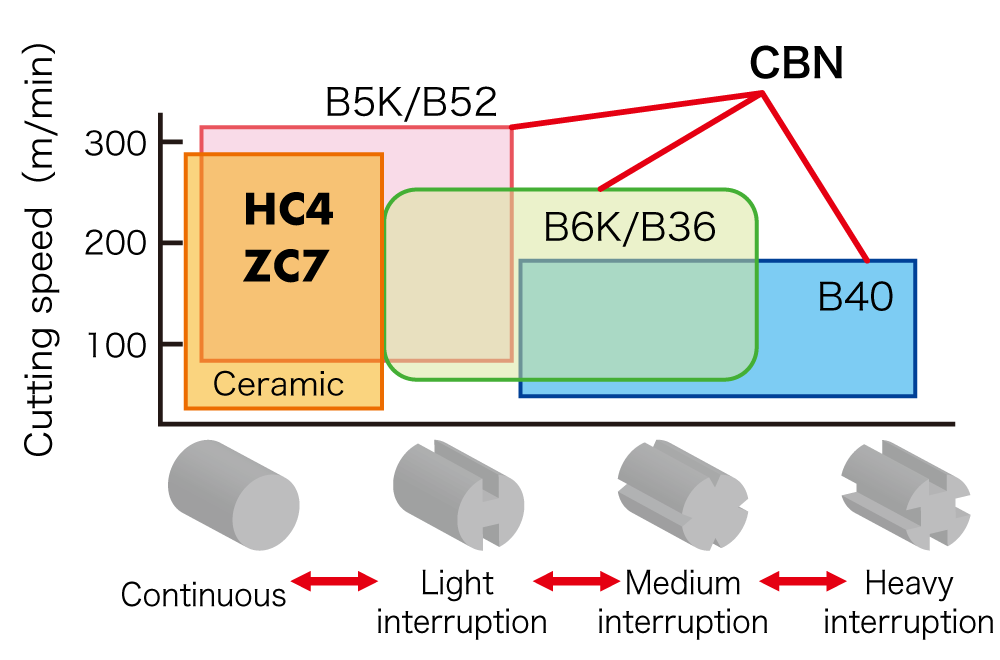

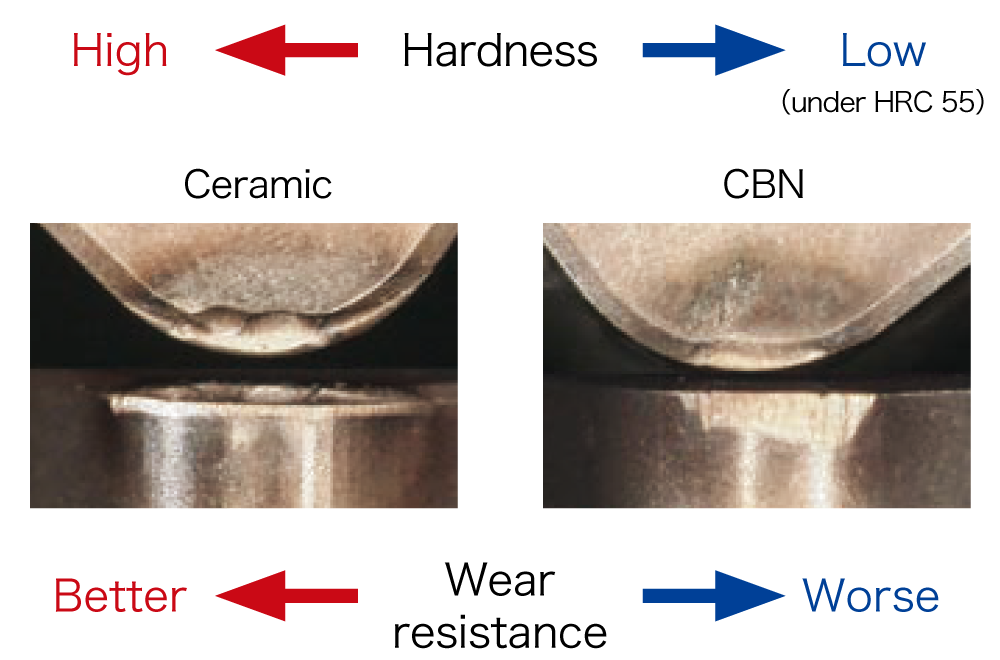

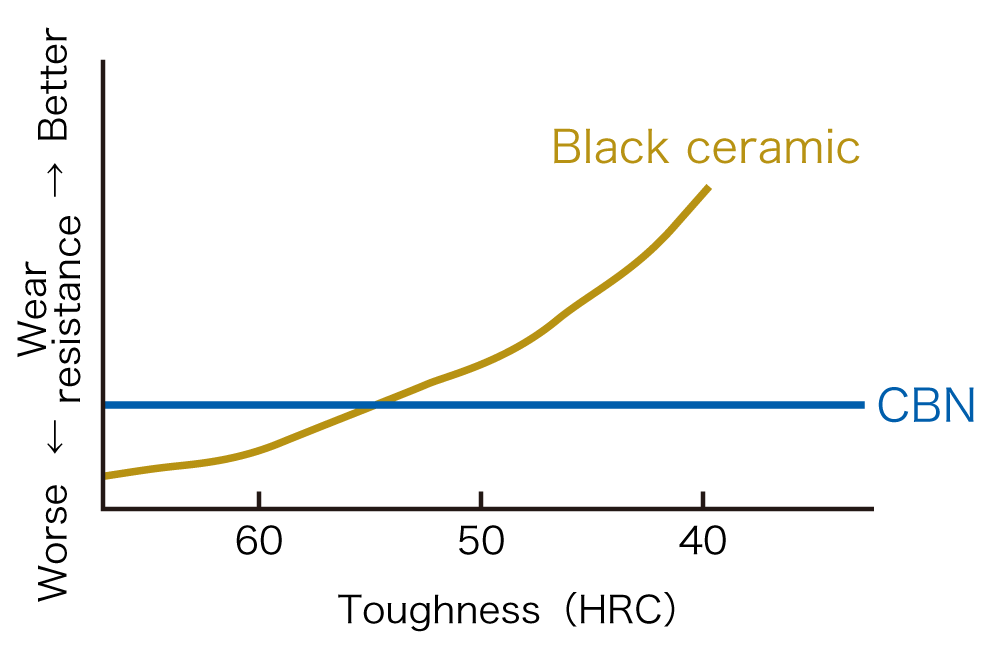

Grade application map

- CBN's low hardness reduces its wear resistance

- Ceramic has superior wear resistance vs. CBN machining under HRC55

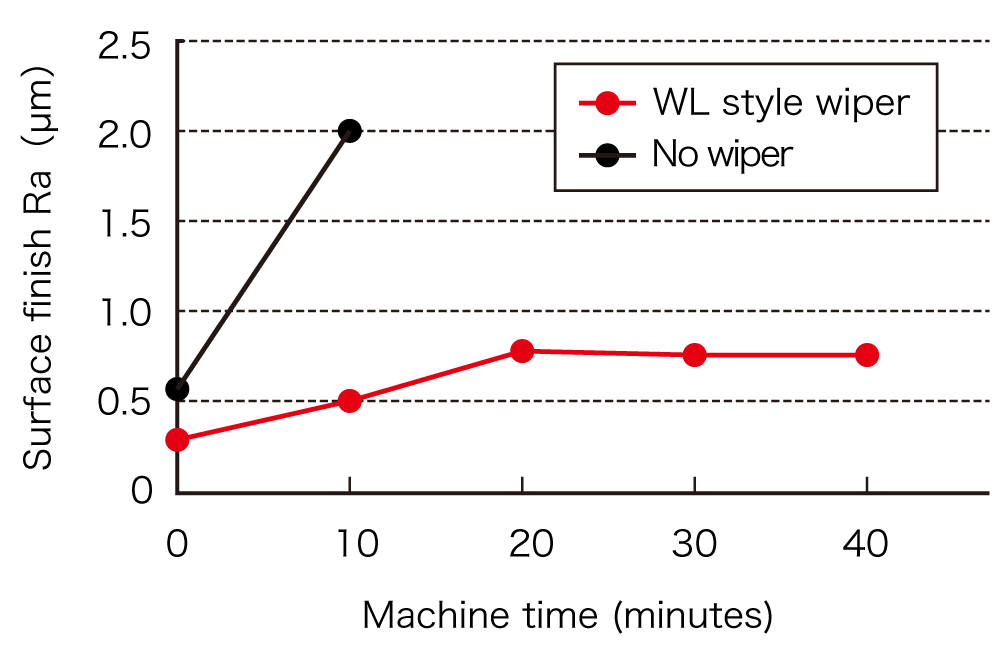

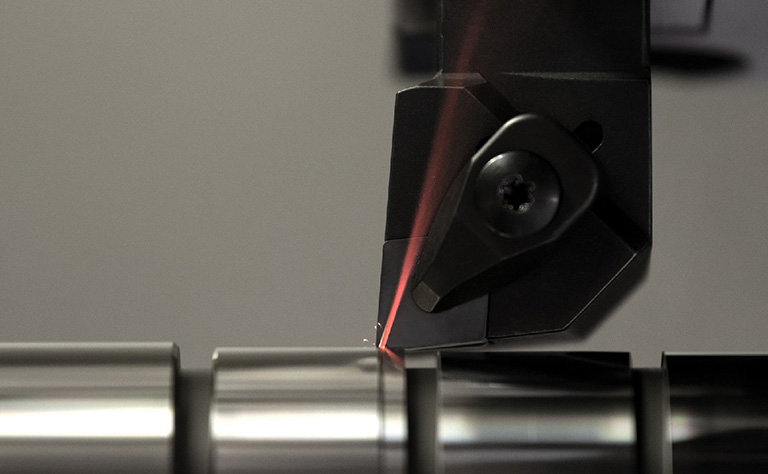

Inserts with a wiper flat or a chipbreaker are available

- Effect of Wiper Flat on Cutting Edge

- [ Cutting conditions ]

- CNGA433 Vc = 100m/min F = 0.1㎜/rev ap = 0.5㎜

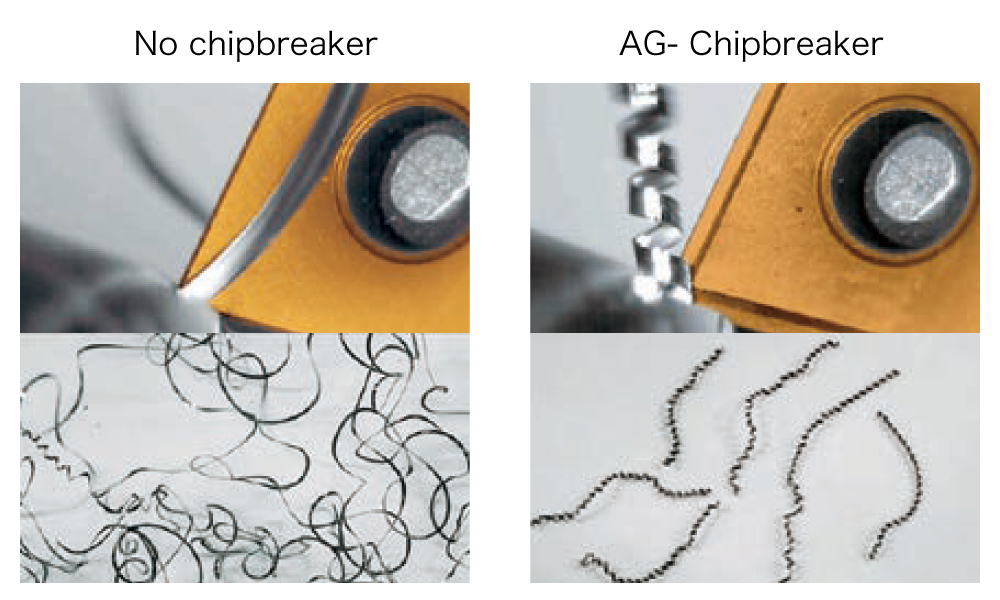

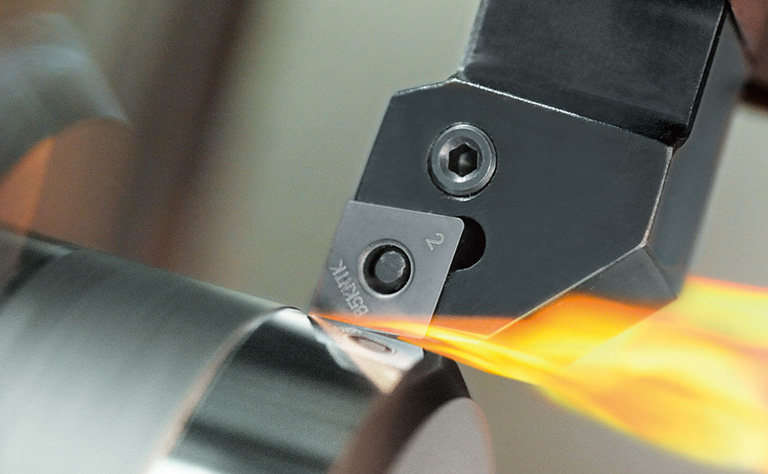

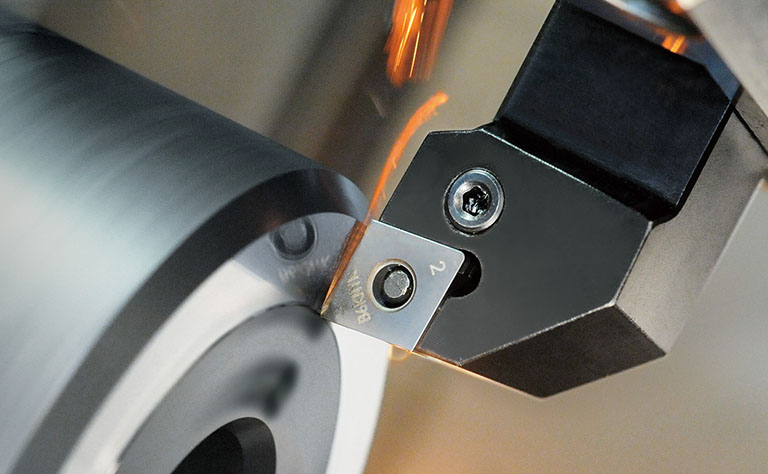

- Using a ZC7 insert with AG-chipbreaker improves surface finish and reduces machine down-time due to chip tangling. This results in increased productivity.

- [ Cutting conditions ]

- SCM415 - carburized HRC50 vc = 150m/min f = 0.2㎜/rev ap = 0.2㎜

Case study

| Gear | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

| ZC7 ( 4 corner ) | 70 pcs / corner |

|

| Competitor’ CBN ( 2 corner ) | 50 pcs / corner |

|

- ZC7 achieved longer tool life per corner and significantly reduced tool costs with 4 corners compared to the competitor's 2 corner CBN.

| Industrial part | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

| ZC7 | 50pc/month - stable machining |

|

| Competitor’ CBN | 50 pcs/month - unstable machining |

|

- ZC7 machined the same number of parts as the competitor's CBN.

ZC7 performance was much more stable and significantly reduced tool costs for the customer.

Tool lineup

Please check product catalog for tooling lineup

Other recommended products

-

NTK450For continuous machining | NTK CeramiX

The ultimate ceramic grade for finishing hardened materials -" NTK CeramiX "

-

B5K/B52For continuous-light interruption machining | CBN for machining hardened material

High performance, low cost, versatile CBN

-

B6K/B36For light to medium interrupted machining | CBN for machining hardened material

High performance, low cost CBN

-

B40For heavy interrupted machining | CBN for machining hardened material

High performance, low cost CBN

Useful information

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕 Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕 Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics

Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics How to Make Ceramic Cutting Tools from Scratch

How to Make Ceramic Cutting Tools from Scratch