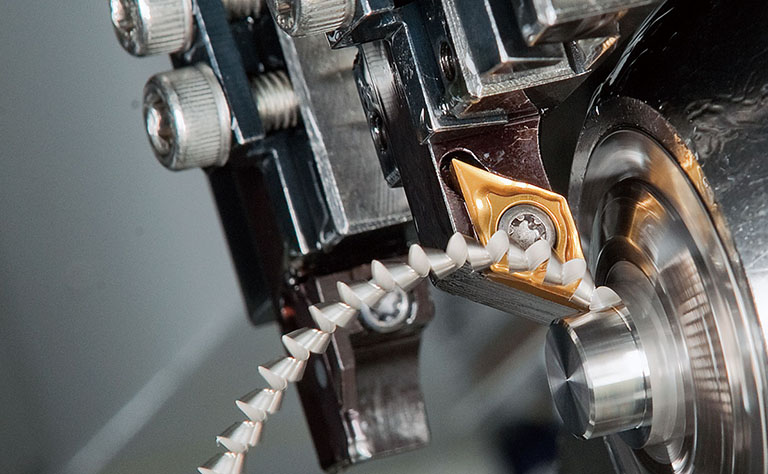

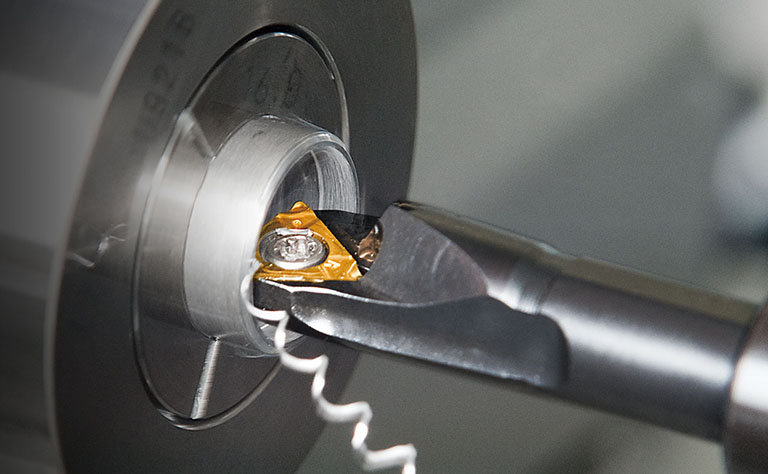

For end milling| Swiss CNC lathes

For end milling| Swiss CNC lathes

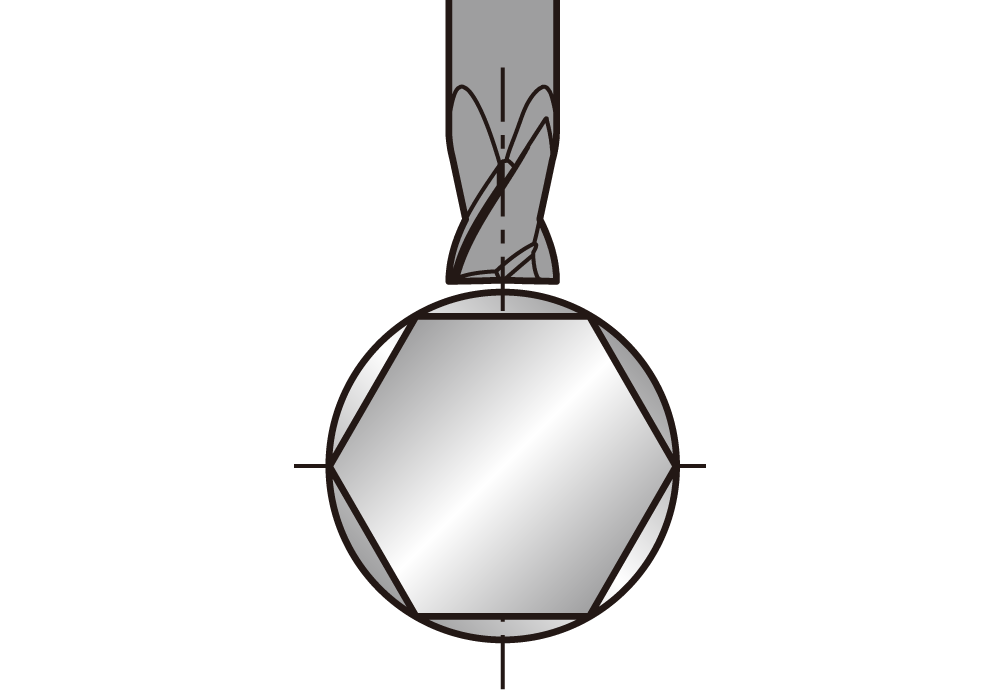

NTK's unique design for sharpness

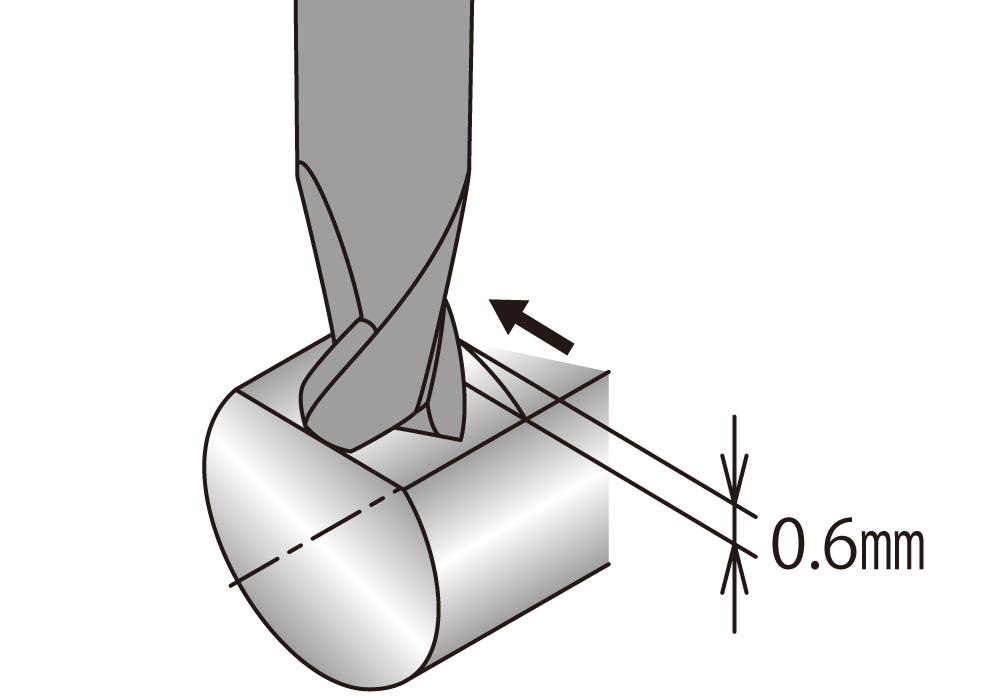

Ideal for small diameter parts that are prone to vibrations

Targets small diameter parts with rigidity issues that benefits from a sharp cutting edge.

Product video

Features

- Designed to focus on sharpness

- Stable machining of even the smallest workpieces

- New AC3 grade with a thin TiACrN-TiAlN coating for wear resistance

Tooling application

Swiss CNC lathes End milling

Cutting conditions

Scroll the table →

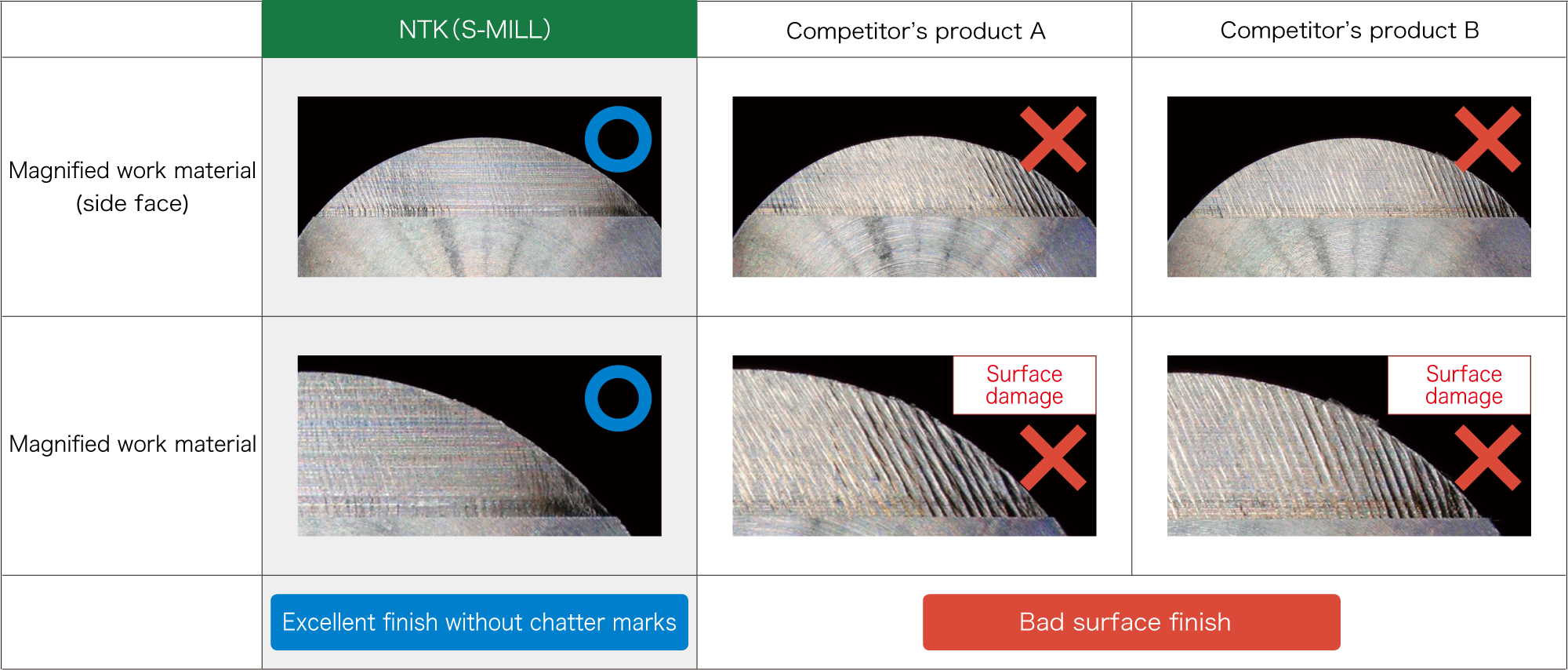

Part surface finish comparison

Scroll the table →

- [ Cutting conditions ]

- Material : SUS304 Φ16.0 ap=3.0㎜ ae=1.2㎜ S = 3,000rpm F = 300㎜/min

- [ Tools used ]

- Φ6.0mm - 2 flute

Case study

| φ6mm - 2 flute D-Cut | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| S-MILL | 12,000 pcs / corner+α |

| Competitor's solid endmill | 10,000 pcs / corner |

The competitor's end mill showed an obvious decrease in surface finish quality as it reached the end of its tool life.

The S-Mill maintained a quality finish throughout the extent of its long tool life.

| φ6mm - 2 flute φ10mm → AF 8mm hexagon | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| S-MILL | 70 pcs / corner+α |

| Competitor's solid endmill | 50 pcs / corner |

The S-Mill's sharpness reduced the occurrence of burrs and increased tool life compared to competitor's tool.

The sharp cutting edge also produced noticeably less sound than the current tool.

Tool lineup

Please check product catalog for tooling lineup

Other recommended products

-

CL chipbreakerFor front turning operations | Swiss CNC Lathes

Sharpest molded chipbreaker

-

CTP/CTPA-CX chipbreakerFor cut-off operations with max. diameter up to 16mm| Swiss CNC lathes

Tightly curls chips to prevent tangling

-

Mogul barsFor ID boring operations| Swiss CNC lathes

Solves common issues associated with ID boring operations

-

SHAPER DUOFor socket hole machining| Swiss CNC lathes

Highly productive socket hole machining

Useful information

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining

The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining

Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining "Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab

"Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab