For milling applications | Whisker ceramic for hardened materials

For milling applications | Whisker ceramic for hardened materials

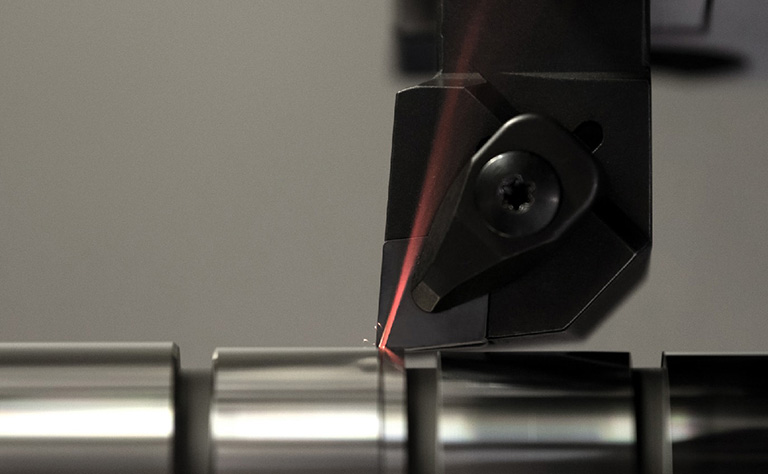

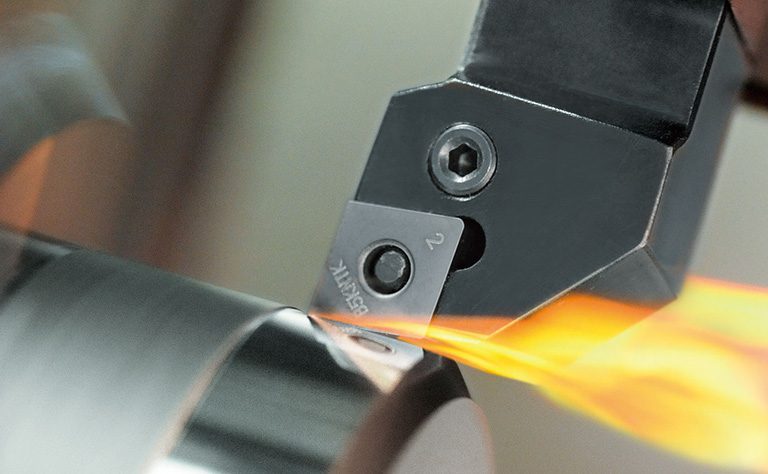

Rapid material removal and long tool life for hard milling

Mill hardened materials (HRC 45-62)

Reduce costs and eliminate grinding

Features

- Mill hardened materials (HRC 45-62)

- Reduce costs and eliminate grinding

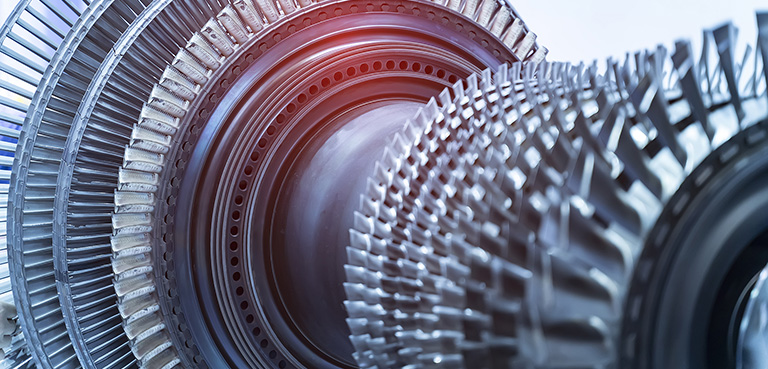

Tooling application

Hardened materials from HRC 45-62

Tool steels, Mold steels, Chilled irons, Powdered metal, Stellite welded overlays, etc.

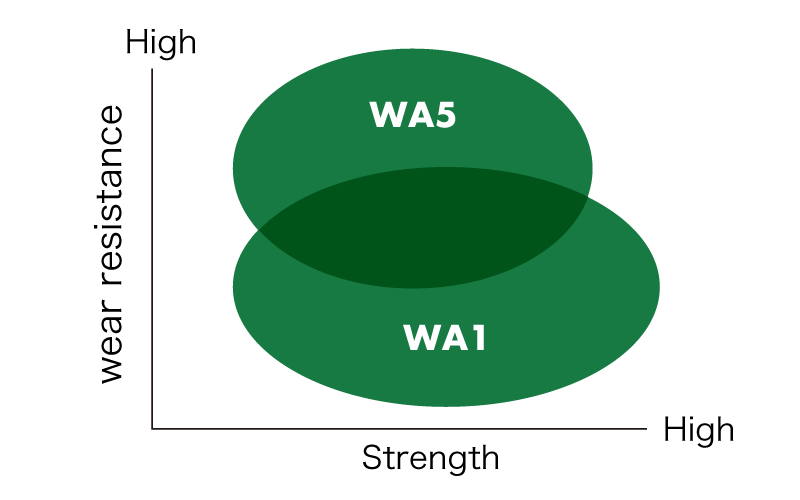

Grade characteristics

Cutting conditions

Scroll the table →

| Insert | DOC(mm) | HRC 45-55 | HRC 55-60 | HRC 60-62 | |||

|---|---|---|---|---|---|---|---|

| Cutting speed(m/min) | Feed(mm/t) | Cutting speed(m/min) | Feed(mm/t) | Cutting speed(m/min) | Feed(mm/t) | ||

| RPGN1204 Type | 1.3 | 250 - 390 | 0.12 | 210-360 | 0.08 | 170-330 | 0.07 |

| RNGN1207 Type | 2.0 | 250 - 420 | 0.12 | 210-390 | 0.10 | 170-360 | 0.07 |

Note: Speeds and feeds are approximate starting points

Guidelines for Success

- Minimize overhang and have a rigid set-up

- Keep cutting engagement at 1/2 to 5/8 of the cutter diameter

- Reduce feed by 25% upon entrance and exit of the cut

- Use air blast, do not use coolant

- Use helical interpolation to ramp down into a cavity

- Increase feed rates in corners to compensate for heat loss

- Use climb milling

- Use shrink fit holders whenever possible

- Safety first - machine within recommended conditions

- As DOC gets smaller, speed should increase to compensate for heat loss

- Adjust speed to maximize plastic deformation

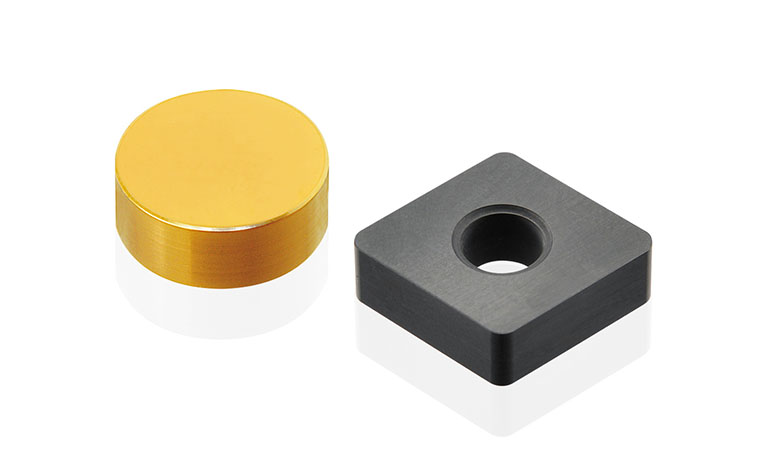

Tool lineup

Scroll the table →

| Geometry | NTK part number | Corner R | Grade | Dimensions (mm) | |||

|---|---|---|---|---|---|---|---|

| Metric part description | Edge preparation | WA1 | WA5 | IC | Thickness | ||

|

RNGN 120700 | T00520 | ― | ● | 12.7 | 7.94 | |

| T00525 | ● | ||||||

| T00820 | ● | ||||||

| T01020 | ● | ||||||

|

RPGN 120400 | T00520 | ― | ● | 12.7 | 4.76 | |

| T01020 | ● | ||||||

Other recommended products

-

NTK450For continuous machining | NTK CeramiX

The ultimate ceramic grade for finishing hardened materials -" NTK CeramiX "

-

ZC7/HC4For continuous machining | Ceramic for machining materials 30 - 70 HRC

Significant cost savings for high hardness materials

-

B5K/B52For continuous-light interruption machining | CBN for machining hardened material

High performance, low cost, versatile CBN

-

B40For heavy interrupted machining | CBN for machining hardened material

High performance, low cost CBN

Useful information

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕 Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕 Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics

Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics How to Make Ceramic Cutting Tools from Scratch

How to Make Ceramic Cutting Tools from Scratch