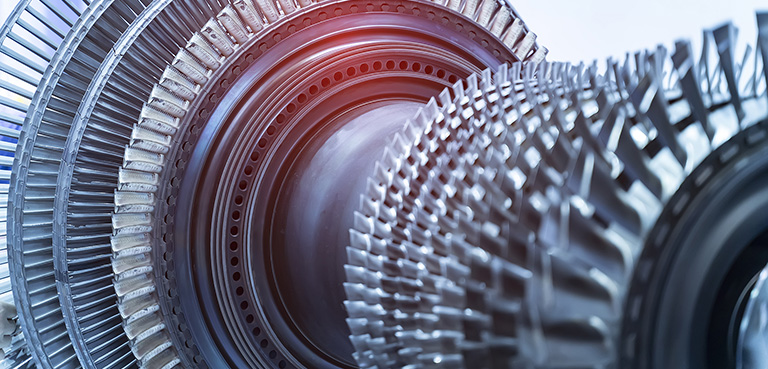

Difficult-to-cut materials | PVD coated carbide

Difficult-to-cut materials | PVD coated carbide

Excellent heat resistance for finishing

Ideal for difficult materials such as heat resistant alloys and titanium alloys

Eliminates the effects of heat on the insert during high temperature machining

High efficiency and long tool life in high precision finishing of difficult to cut materials

Features

- A thick TiAlN coating provides heat resistance to extend tool life

- The combination of heat and wear resistance is ideal for finishing heat resistant alloys and titanium

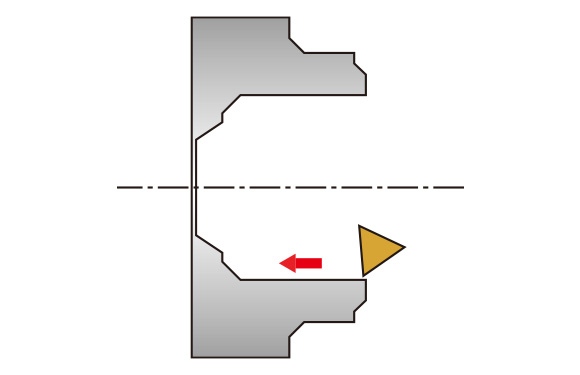

Tooling application

Difficult to cut materials: heat resistant alloys and titanium alloys

Finish Turning / Grooving

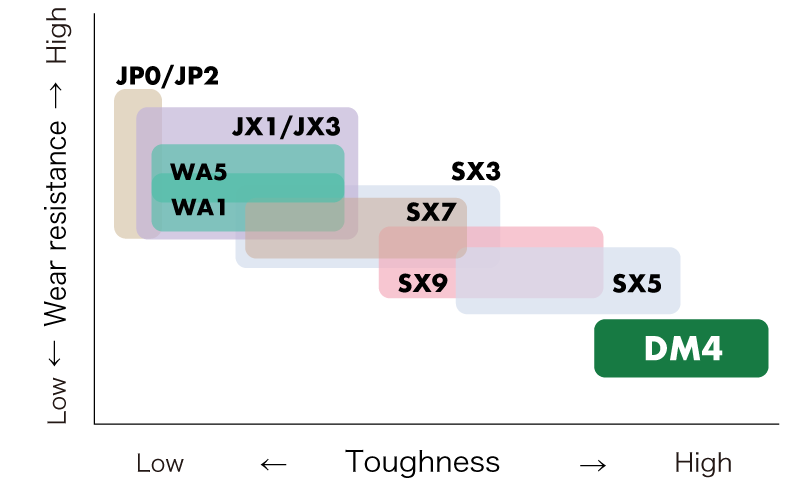

Grade characteristics

Cutting conditions

Scroll the table →

| Grade | Material | Operation type | Machining | Cutting speed (m/min) | Feed(mm/rev) | DOC(mm) | Coolant |

|---|---|---|---|---|---|---|---|

| DM4 | Difficult to cut materials (heat resistant alloys) | Turning | Finishing | 20 - 50 | 0.03 - 0.15 | 0.1 - 1.0 | WET |

| Grooving | 0.05 - 0.20 | - |

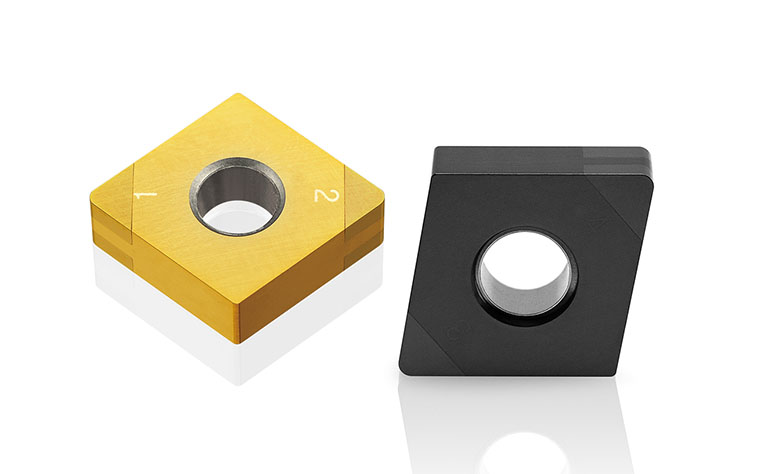

Case study

| Case (finishing) | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| DM4 | 110 pcs / corner |

| Competitor’s PVD coated carbide | 90 pcs / corner |

Tool lineup

Please check product catalog for tooling lineup

Other recommended products

-

SX3Roughing & semi-finishing heat resistant alloys | Sialon ceramic

First recommendation for heat resistant alloys machining

-

WA1/WA5Roughing with no scale to semi-finishing heat resistant alloys | Whisker ceramic

High-speed machining not achievable with carbide tools

-

JX1/JX3Roughing to semi-finishing of heat resistant alloys | BIDEMICS

Revolutionary material for machining heat resistant alloys

-

NTK120/JP2Finishing Heat resistant alloys | BIDEMICS

Machine HRSA materials at speeds of Vc=500 m/min with BIDEMICS

Useful information

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕 Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕 Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics

Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics How to Make Ceramic Cutting Tools from Scratch

How to Make Ceramic Cutting Tools from Scratch