For Steel Machining | BIDEMICS

For Steel Machining | BIDEMICS

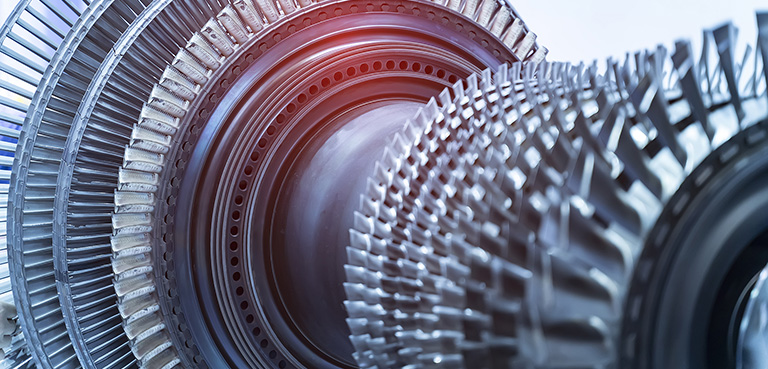

Cutting Steel At 1000m/min

Venture into the unknown

NTK's challenge :Cutting Steel at 1000m/min without a drop of coolant.

Product video

Value to be delivered to the manufacturing

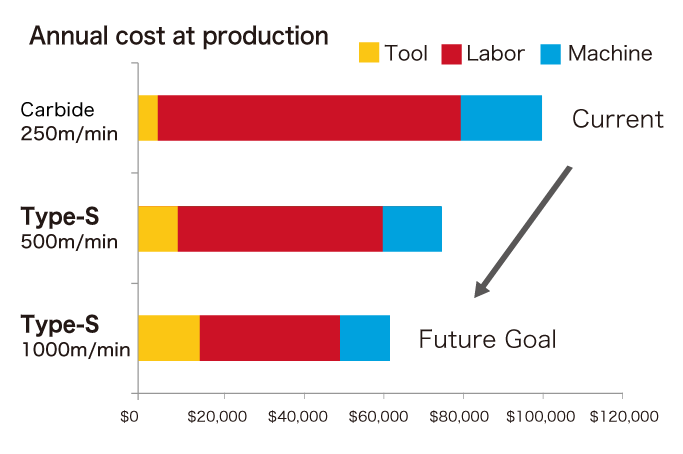

- Reduction of manufacturing cost and effective utilization of capital investment cost by improving productivity by high-speed cutting.

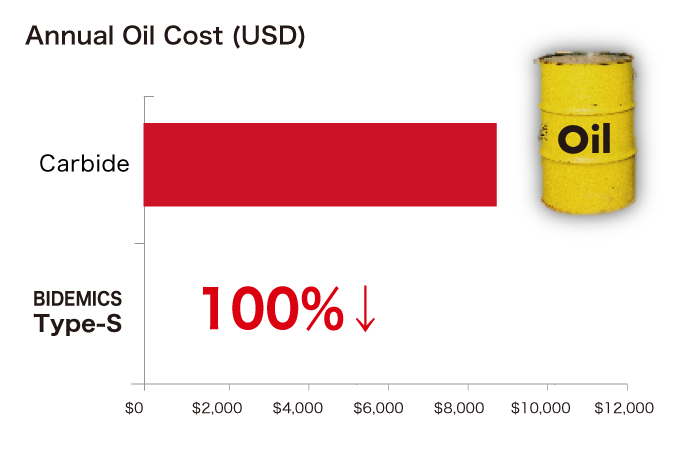

- Reduction of environmental resources by DRY processing.

- Long-term stable supply by reducing dependence on depleting resources. (tungsten carbide, cobalt, etc.)

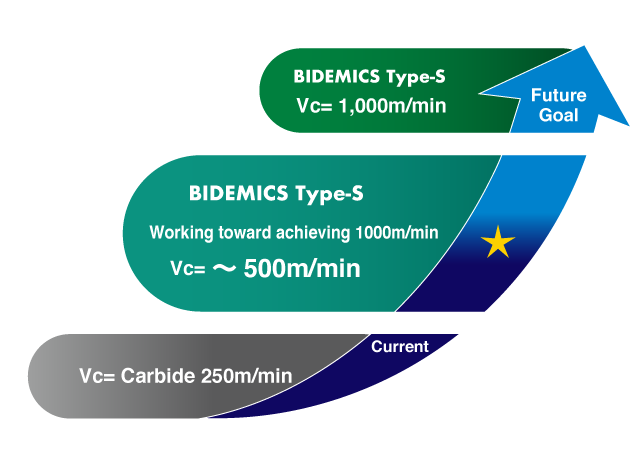

Roadmap

- First of all, we are working on the development of tool materials that can be machined at Vc=500m/min, which is a milestone.

Cutting speed1,000m/min

- NTK is challenging the status quo - to reach speeds far exceeding industry expectations.

Sustainable future

Cut production cost : 40% reduction

No coolant cost

Test Sample

Useful information

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕 Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕 Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics

Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics How to Make Ceramic Cutting Tools from Scratch

How to Make Ceramic Cutting Tools from Scratch