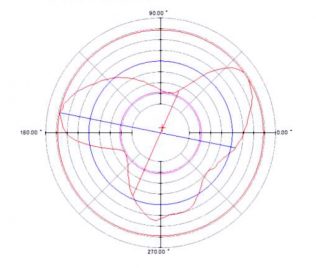

Do you know what the diagram below represents ?

This diagram shows the measurement result of a workpiece that is out of “roundness“.

This diagram shows the measurement result of a workpiece that is out of “roundness“.

Roundness is important for “high precision” CNC automatic lathe machining.

This article will introduce two points to check when “roundness” is not achieved in Swiss-type CNC automatic lathe machining.

Checkpoint when Part Roundness is an issue: ① Guide bushing

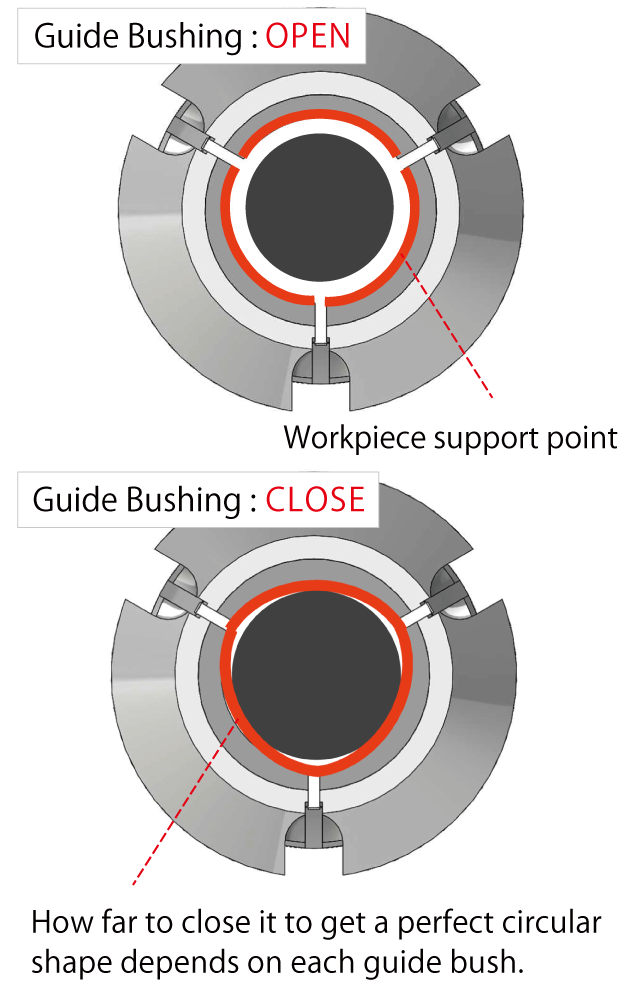

First- Check the Gripping Force of Guide Bushing

The number one cause of lack of part roundness is a problem with the guide bushing.

The distorted shape shown in the figure on the left is the result a weak guide bushing gripping force causing the workpiece material to swing. Therefore, the part roundness is lost.

Countermeasure: Adjust the guide bushings to the proper “gripping force”.

Second- Check for Guide Bushing Variations

When the guide bush is closed, it is important that the workpiece material diameter as evenly as possible.

However, there are individual differences (variations) in the manufacturing of the guide bushings, and how close to a true circle shape when closed differs for every guide bushing.

Therefore, if the compatibility between the guide bush and the workpiece material diameter is poor, the workpiece material is supported by “point contact,” which affects roundness.

Countermeasure: Replace the guide bushing with one with better accuracy (better gripping of the workpiece evenly).

Third- Check guide bushing for deteriorating performance

If the guide bush has been used for a long time, the work support part (cemented carbide) will wear over time. As a result, the workpiece holding accuracy may become unstable and roundness may not be obtained.

Countermeasure: Please check your guide bushing.

Checkpoint when Part Roundness is an issue: ② “Cutting tool”

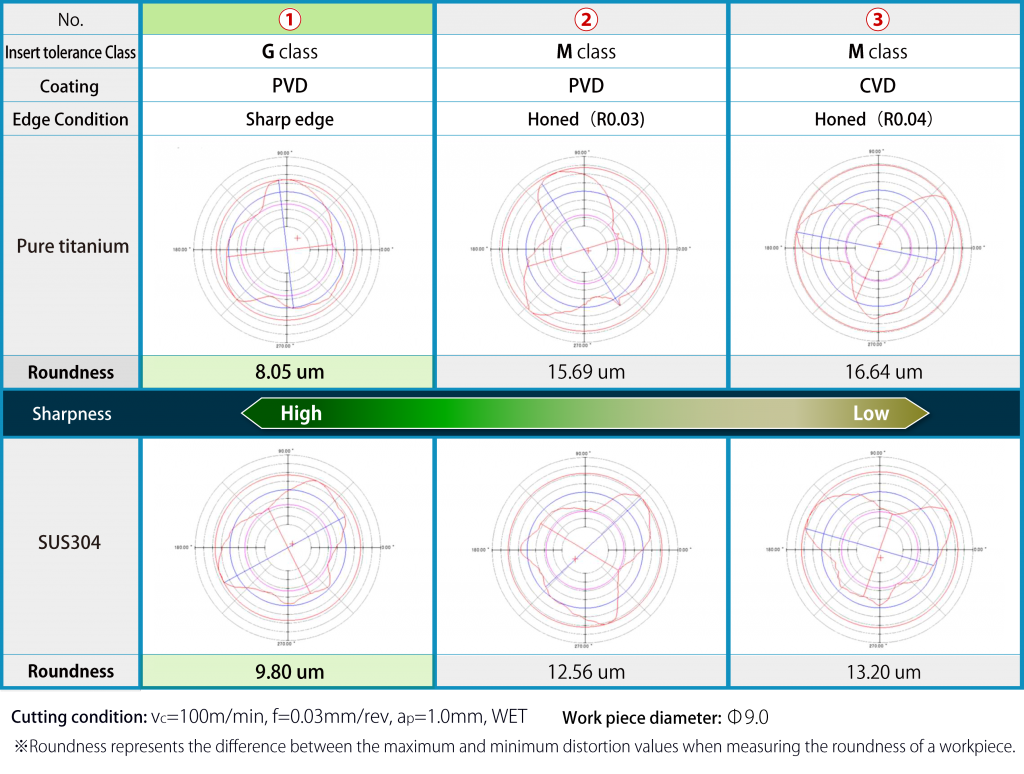

The second cause of lack of part roundness is the cutting tool. Here, sharpness is the key factor.

As mentioned in the previous NTK articles, Swiss-type CNC automatic turning requires high precision machining of small-diameter workpieces, so cutting tools with good sharpness are necessary.

In the above figure, pure titanium and SUS304 are machined with three cutting tools with differing sharpness, and roundness is measured.

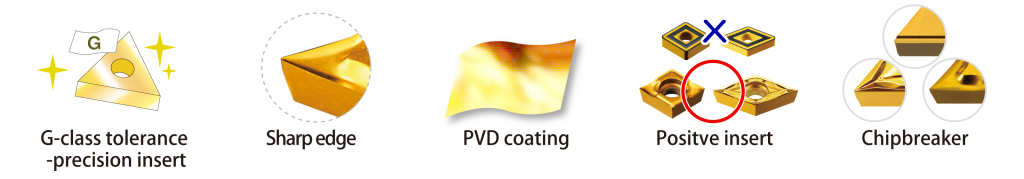

The above No. ① is “G-grade tolerance*”, “PVD coating”, and “sharp edge” making it the cutting tool with the highest degree of sharpness.

Good sharpness lowers the cutting forces and prevents the work material from being pressed against the guide bush. As a result, good roundness may be obtained.

G class tolerance inserts: Tools with a polished outer circumference.

Countermeasure: To achieve roundness, use a cutting tool with the following specifications that is sharp.

Factors influencing sharpness

We hope you found the information in this article to be useful for effectively machining parts on you Swiss-type CNC automatic lathe.

NTK offers a large lineup of tools specialized for CNC automatic lathes. If you are having issues machining,

please consider it our tools and contacting us for technical advise.