For ID boring operations| Swiss CNC lathes

Swiss CNC lathes ID boring operations

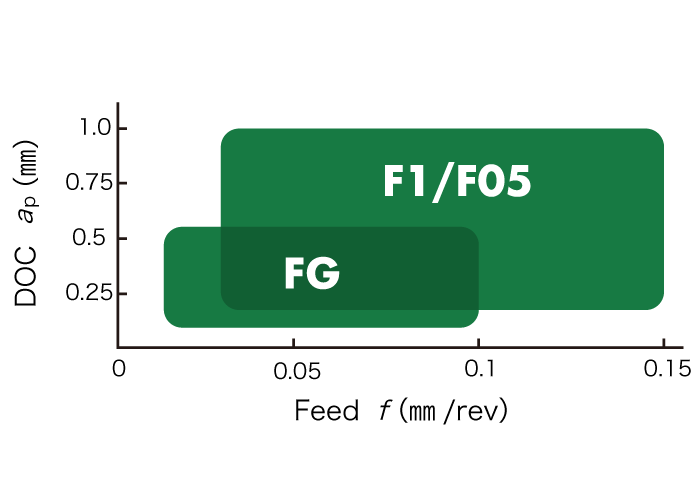

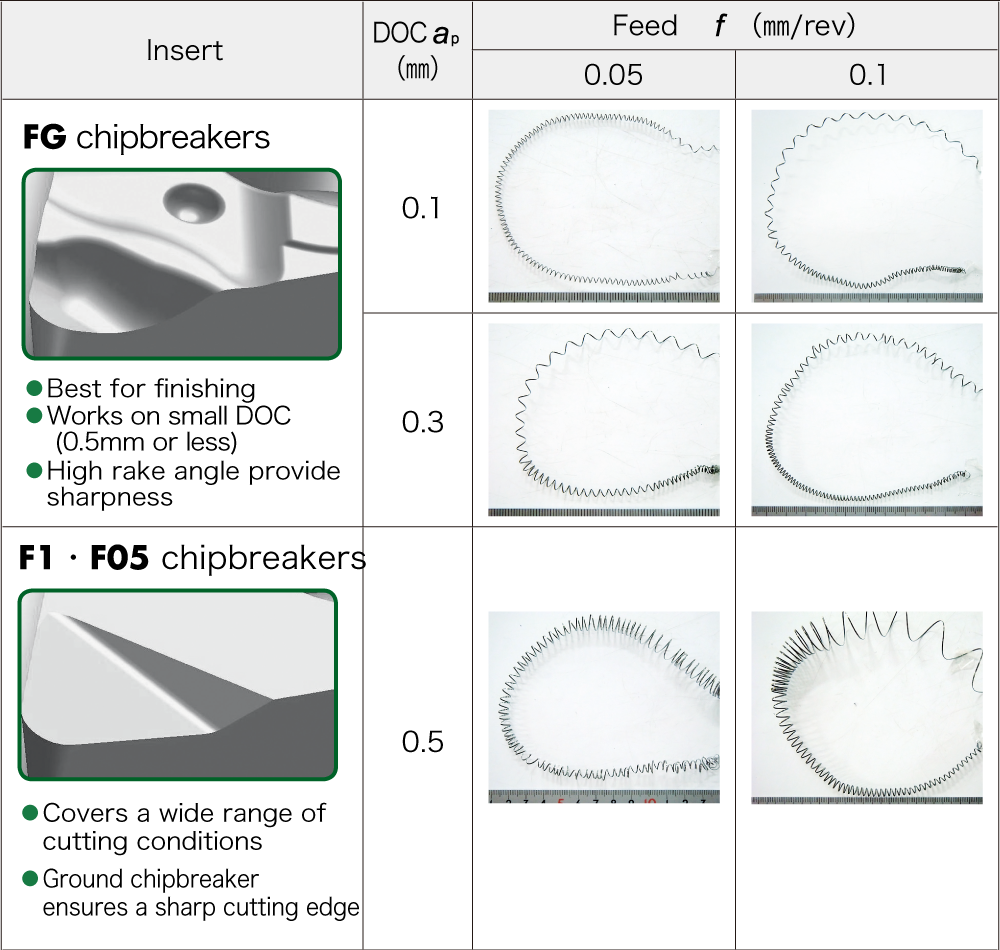

[ Cutting conditions ]

Material : Alloy steel・Stainless steel

vc = 80m/min f=0.05-0.1mm/rev ap=0.1-0.5mm

260 SFM .002 – .004 IPR .004 – .020 DOC

WET

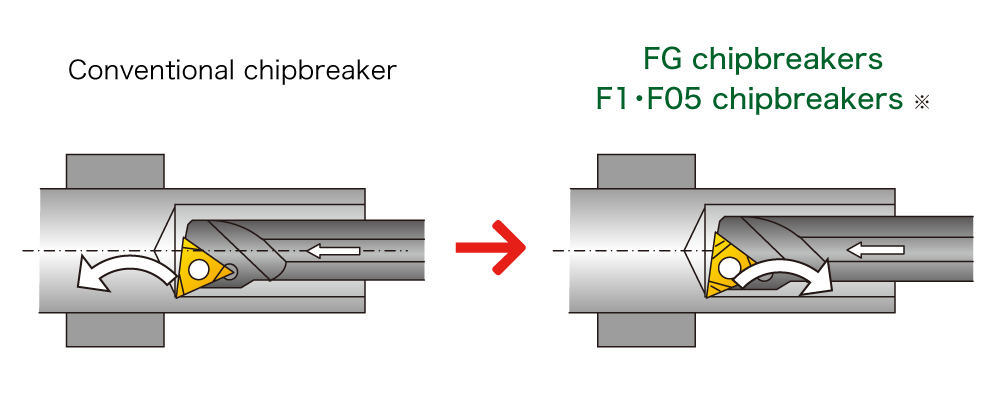

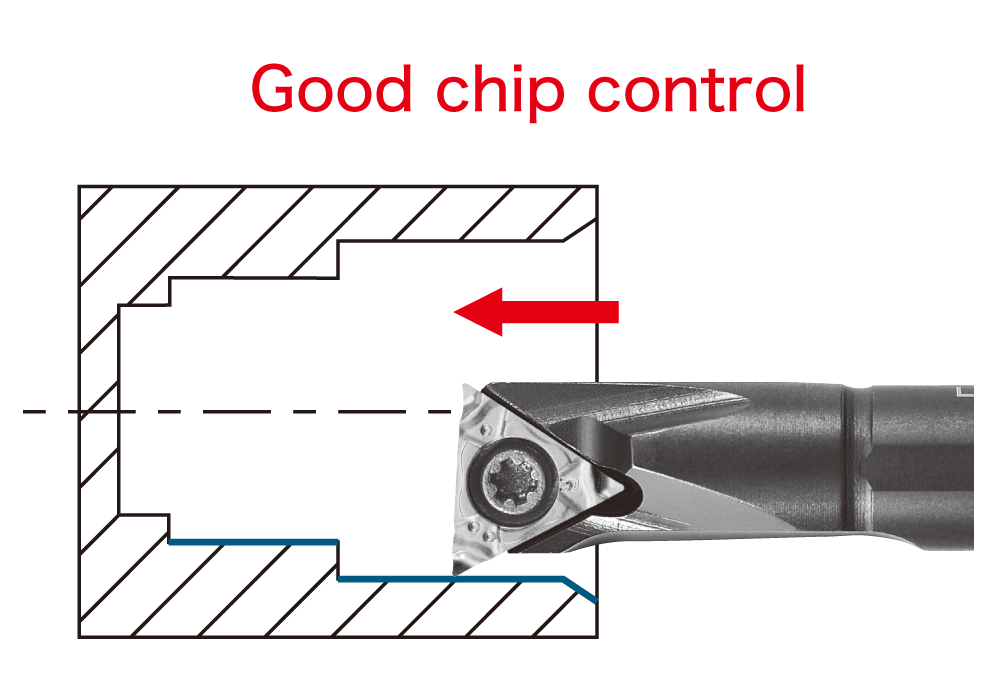

F style chipbreakers direct chips backward and out of the hole

* Use a right-handed style insert with a right-handed boring bar

[ Cutting conditions ]

Material : SCM415

part diameter ⌀12 Machining depth 20mm vc = 80m/min

part diameter ⌀.472” 260 SFM Depth of Bore : .787”

WET(External coolant)

[ Tools used ]

Holder : Steel shank S10KSTUPR11D12-OH Insert :

TPGH110304 Type

TPGH221

*When using FG, F1, F05 chipbreakers – use a right-handed insert with a right-handed boring bar.

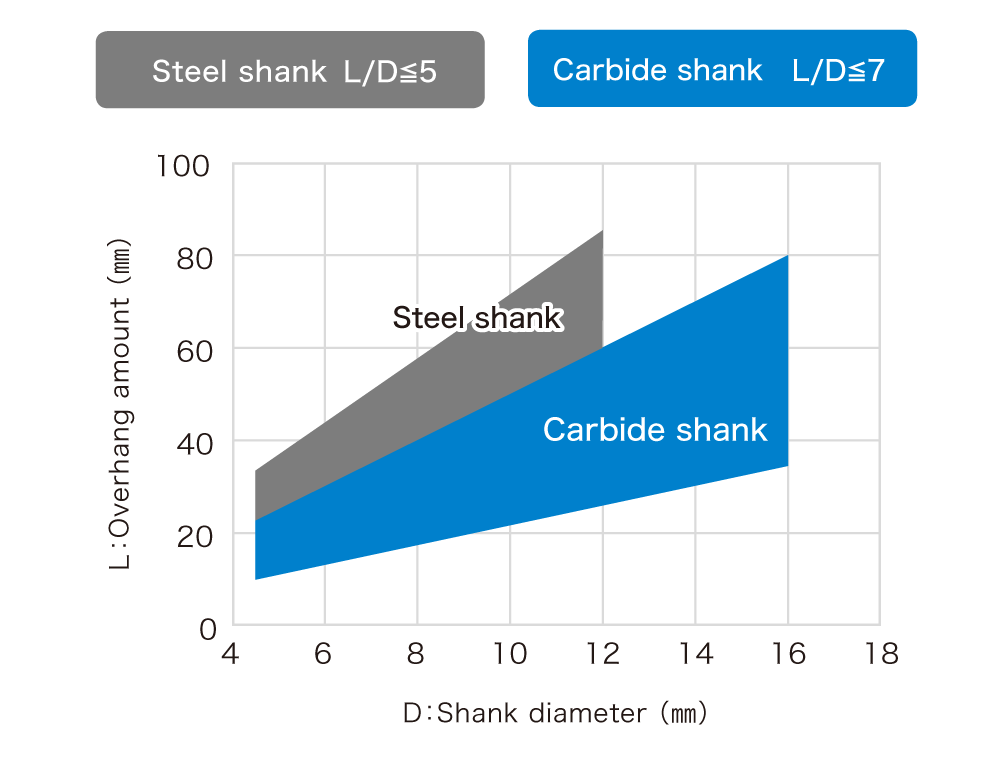

| Coated grade | Material | Operation type | Overhang amount | Cutting speed (m/min) Cutting speed (SFM) | Feed (mm/rev) Feed (IPR) | DOC (mm) DOC (inch) |

|---|---|---|---|---|---|---|

| ST4 | Stainless | ID boring operations ID boring Back turning | Steel shank ~5D Carbide shank ~7D | 40 – 120 130 – 400 | 0.02 – 0.2 .0008 – .005 | 0.1 – 1.0 .004 – .080 |

| QM3 | Alloy steel / carbon steel / hardened material | 50 – 150 150 – 500 | ||||

| DM4/DT4 | Difficult-to-cut material / titanium alloy / high temp alloys | 30 – 70 130 – 330 | ||||

| TM4/ZM3 | Non-ferrous / aluminum / plastic / general purpose | 50 – 200 150 – 600 |

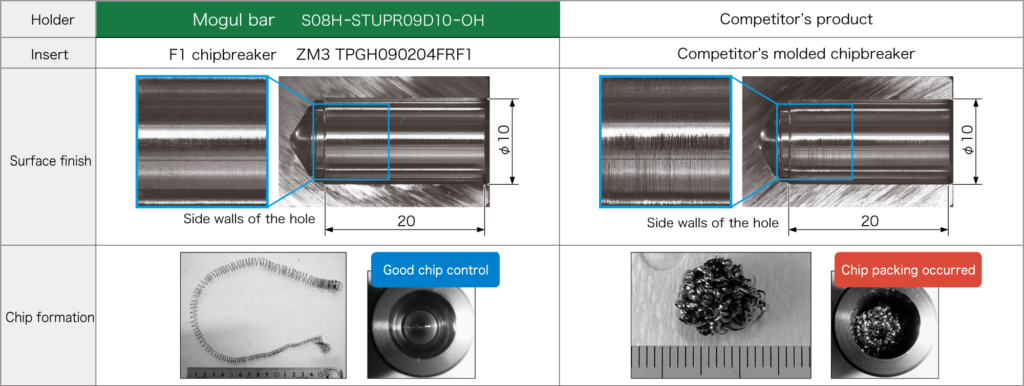

[ Cutting conditions ]

Material : SCM435

vc = 80m/min f = 0.05mm/rev ap = 0.25㎜ part diameter : ⌀10 External coolant Toolholder overhang amount : L/D = 4 Machining depth : 20mm

270 SFM .002 IPR .010 DOC part diameter:⌀.39” External coolant Toolholder overhang amount : L/D = 4 Machining depth : .79”

[ Tools used ]

Holder : S08H-STUPR09D10-OH type

(minimum bore diameter of ⌀10) Shank diameter : ⌀8

(minimum bore diameter of ⌀.39”) Shank diameter : ⌀.315”

Insert : TPGH090204 Type

| Valve parts | |

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

| Mogul bars +TM4 FGbreaker |

1,500 pcs

|

| Competitor’s product |

700 pcs

|

Competitor’s tool life was not stable due to chip packing.

NTK’s mogul bar and insert with FG chipbreaker evacuated the chip from the hole resulting in a 2.1 x increase in tool life.

| Sleeve | |

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

| Mogul bars +TM4 F1breaker |

900 pcs

|

| Conventional tool |

500 pcs

|

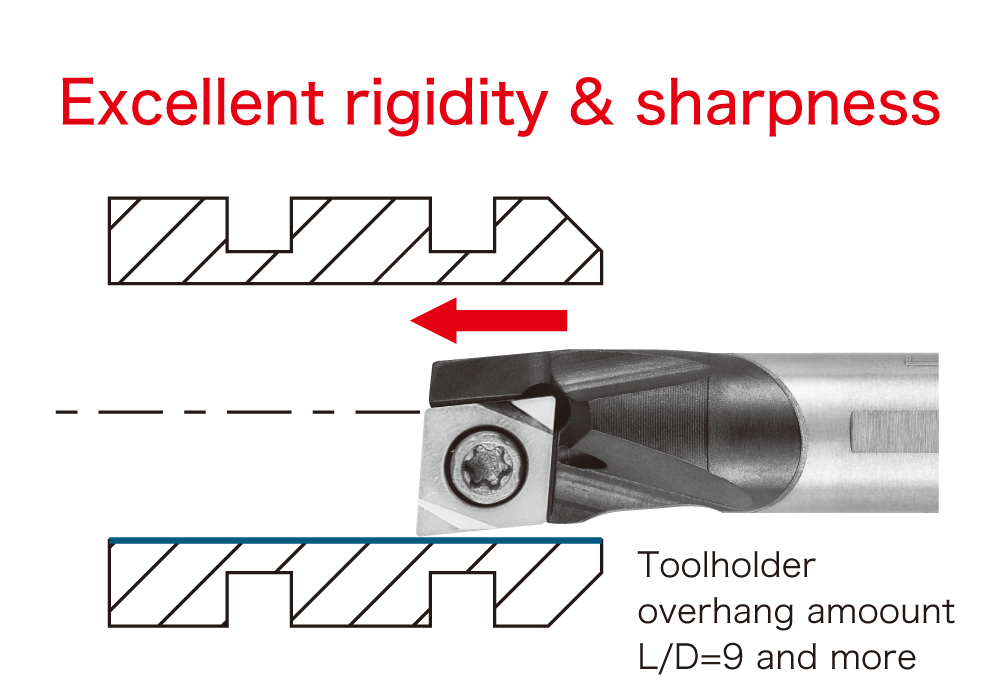

The competitor’s boring bar experienced a heavy amount of vibration due to extended overhang.

NTK’s boring bar eliminated vibration issues and insert with F1 chipbreaker achieved 1.8 x more tool life.

For more information about this product, visit our online e-catalog, or download the catalog/product report