Mogul barsFor ID boring operations| Swiss CNC Lathes

Solves common issues associated with ID boring operations

Highly rigid bars and inserts that direct chips away from the part

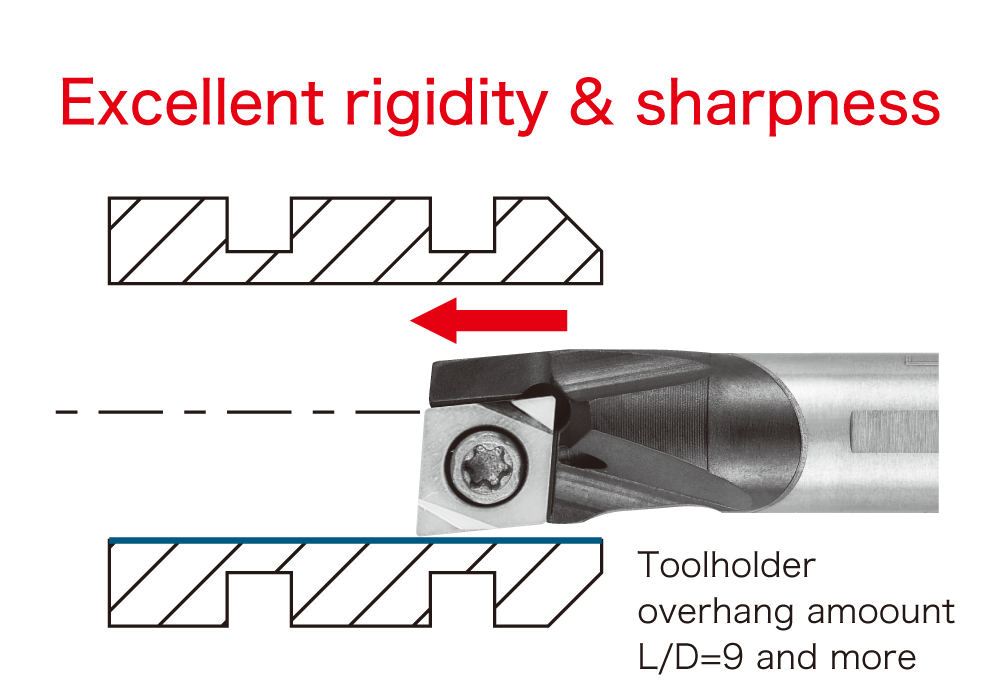

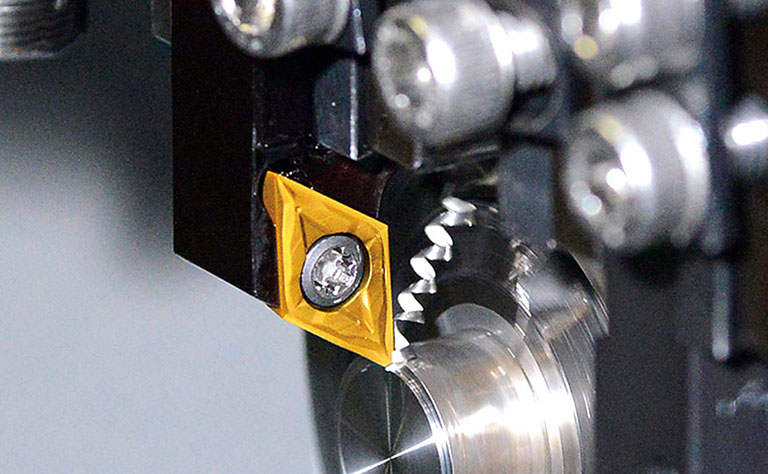

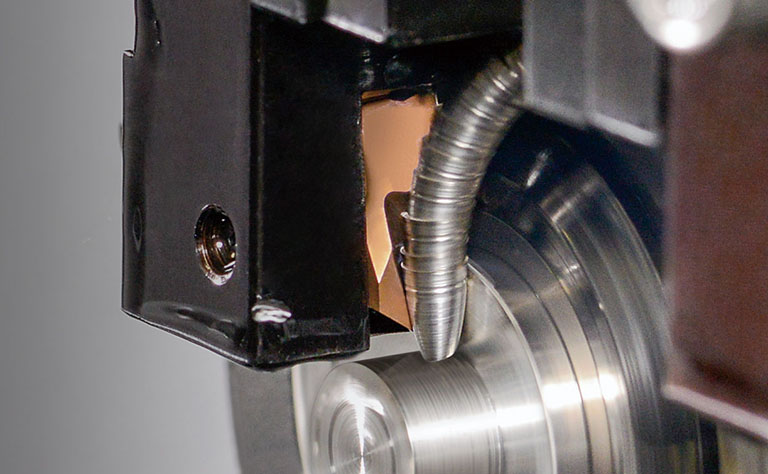

Unique boring bar design greatly improves rigidity combined with chipbreakers that control the direction of the chip evacuation during the boring operation.

Product video

Features

- Holder designed to ensure rigidity and eliminate vibrations

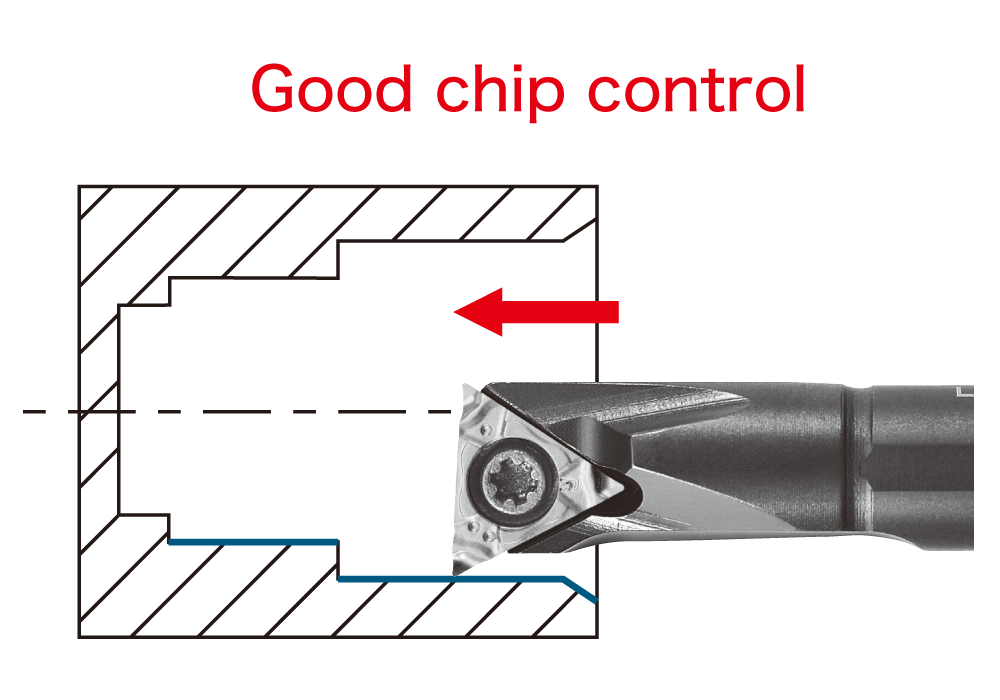

- F1, F05, FG chipbreakers developed for blind hole applications to direct chips backward and out of the hole to prevent chip packing

- Coolant through boring bars to support chip evacuation

Tooling application

Swiss CNC lathes ID boring operations

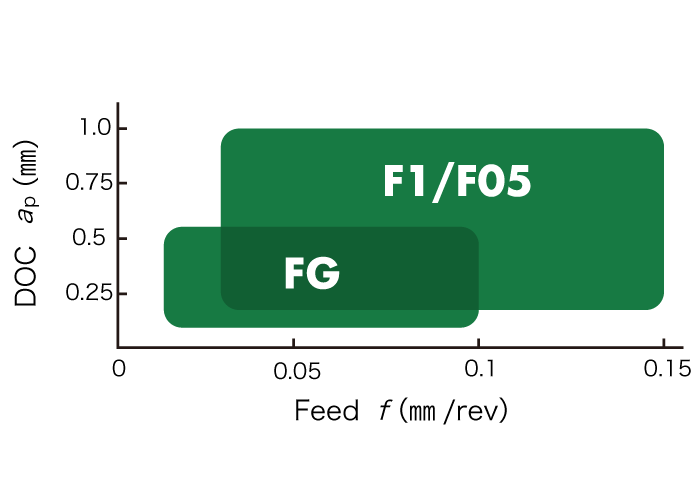

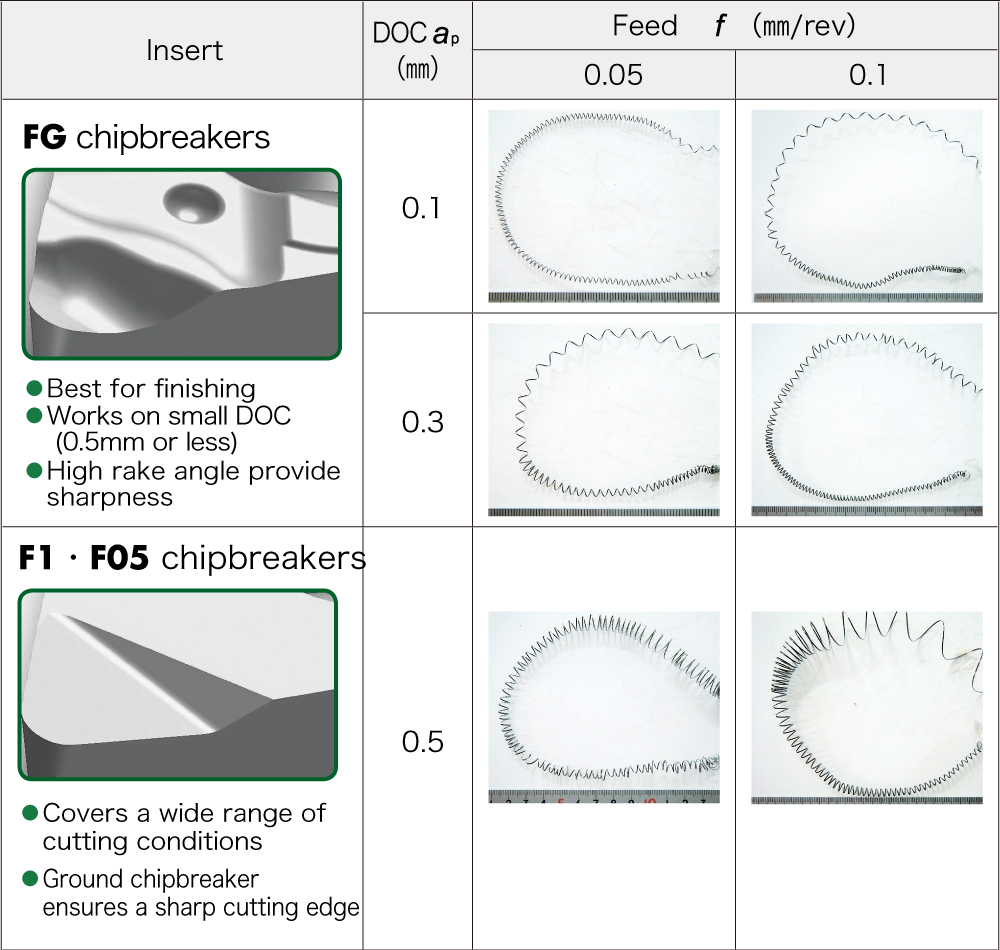

Chipbreaker control range

Cutting conditions

Scroll the table →

| Coated grade | Material | Operation type | Overhang amount | Cutting speed (m/min) | Feed (mm/rev) | DOC (mm) |

|---|---|---|---|---|---|---|

| ST4 | Stainless | ID boring operations ID boring Back turning |

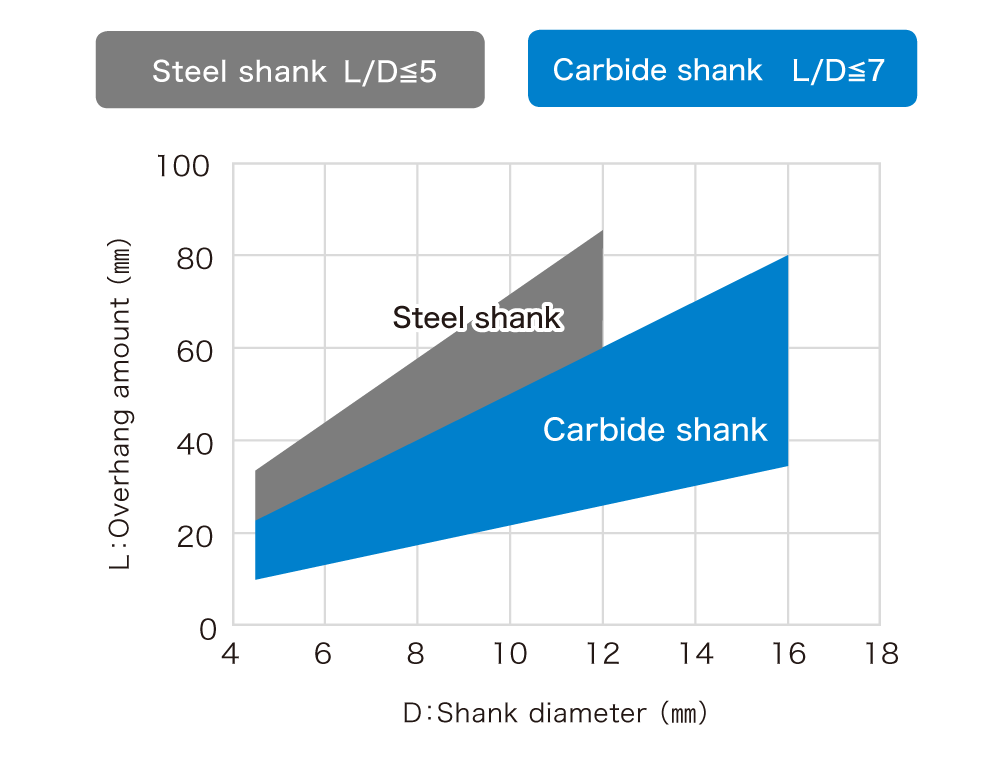

Steel shank ~5D Carbide shank ~7D |

40 - 120 | 0.02 - 0.2 | 0.1 - 1.0 |

| QM3 | Alloy steel / carbon steel / hardened material | 50 - 150 | ||||

| DM4/DT4 | Difficult-to-cut material / titanium alloy | 30 - 70 | ||||

| TM4/ZM3 | Non-ferrous / aluminum / plastic / general purpose | 50 - 200 |

Toolholder overhang

- [ Cutting conditions ]

- Material : Alloy steel・Stainless steel vc = 80m/min f=0.05-0.1mm/rev ap=0.1-0.5mm WET

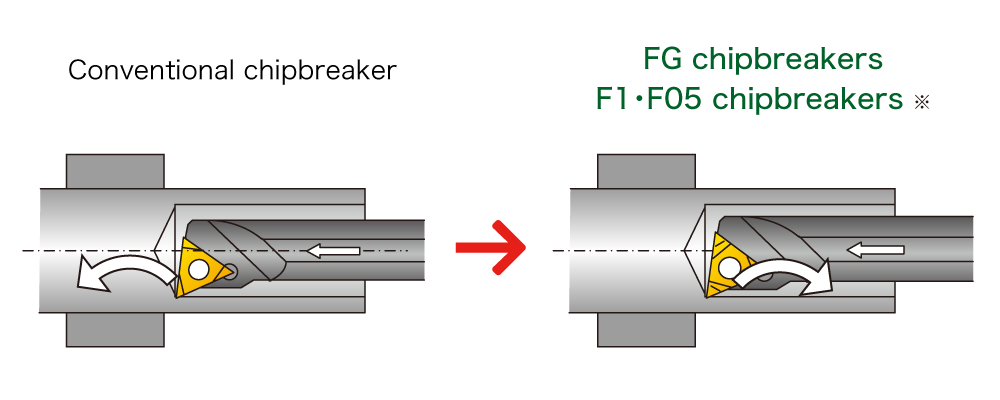

Evacuates chips Backwards

F style chipbreakers direct chips backward and out of the hole

* Use a right-handed style insert with a right-handed boring bar

Features of FG / F05 / F1 chipbreakers

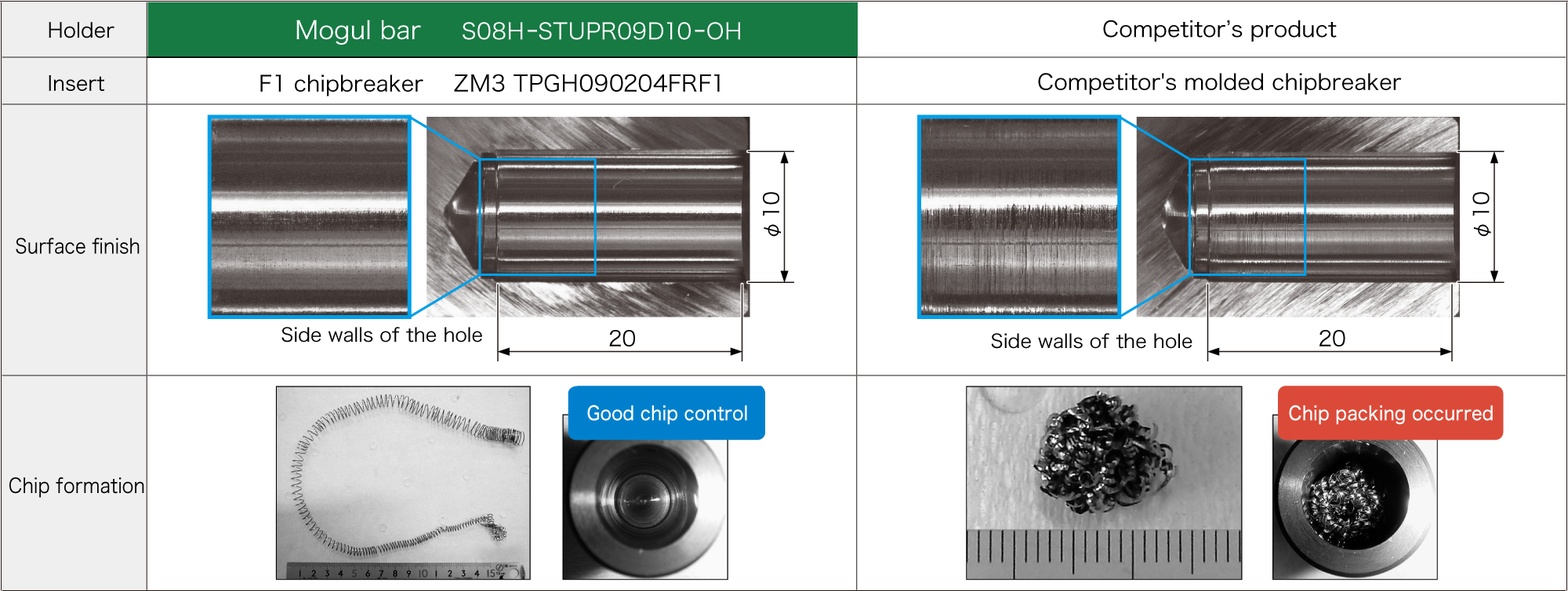

- [ Cutting conditions ]

- Material : SCM415 part diameter φ12 Machining depth 20mm vc = 80m/min WET(External coolant)

- [ Tools used ]

- Holder : Steel shank S10KSTUPR11D12-OH Insert : TPGH110304 Type

Chip control

Scroll the table →

- [ Cutting conditions ]

- Material : SCM435 vc = 80m/min f = 0.05㎜/rev ap = 0.25㎜ part diameter : φ10 External coolant Toolholder overhang amount : L/D = 4 Machining depth : 20㎜

- [ Tools used ]

- Holder : S08H-STUPR09D10-OH type (minimum bore diameter of φ10) Shank diameter : φ8 Insert : TPGH090204 Type

Case study

| Valve parts | |

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

| Mogul bars +TM4 FGbreaker |

1,500 pcs |

| Competitor’s product | 700 pcs |

Competitor's tool life was not stable due to chip packing.

NTK's mogul bar and insert with FG chipbreaker evacuated the chip from the hole resulting in a 2.1 x increase in tool life.

| Sleeve | |

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

| Mogul bars +TM4 F1breaker |

900 pcs |

| Conventional tool | 500 pcs |

The competitor's boring bar experienced a heavy amount of vibration due to extended overhang.

NTK's boring bar eliminated vibration issues and insert with F1 chipbreaker achieved 1.8 x more tool life.

Tool lineup

Other recommended products

-

CTP/CTPA-CX chipbreakerFor cut-off operations with max. diameter up to 16mm| Swiss CNC lathes

Tightly curls chips to prevent tangling

-

SPLASH seriesCoolant through toolholders | Swiss CNC Lathes

Extensive selection of styles and sizes

-

YL chipbreakerFor front turning operations | Swiss CNC Lathes

First recommendation for front turning

-

The Front MaxFor front turning operations | Swiss CNC Lathes

Single pass machining of up to 5.0mm depth of cut

Useful information

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining

The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining

Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining "Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab

"Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab