Solid Ceramic End Mill

Features

4 flute type

Designed purpose of toughness

6 flute type

Less tool pressure and better chip evacuation

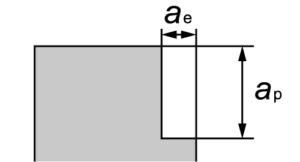

| Application | Application Flute | ⌀D(mm) ⌀D(inch) | Depth of cut(mm) Depth of cut(inch) ap | Width of cut(mm) Width of cut(inch) ae | Feed(mm/t) Feed(IPM) | Cutting speed (m/min) Cutting speed (SFM) | Coolant |

|---|---|---|---|---|---|---|---|

Side Milling

|

4/6/8 | 8 .315 | ≦4.0 ≦.157 | ≦0.8 ≦.031 | 0.03 .001 | 300 – 600 – 1000 980 – 1970 – 3280 | DRY |

| 10 3/8 | ≦5.0 ≦.197 | ≦1.0 ≦.039 | 0.03 .001 | ||||

| 12 1/2 | ≦6.0 ≦.236 | ≦1.2 ≦.047 | 0.03 .001 | ||||

| 16 5/8 | ≦8.0 ≦.315 | ≦1.6 ≦.063 | 0.03 .001 | ||||

| 20 3/4 | ≦10.0 ≦.398 | ≦2.0 ≦.079 | 0.03 .001 | ||||

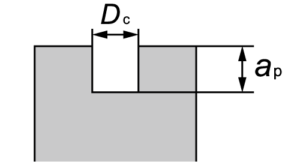

Slotting

|

4 | 8 .315 | ≦2.0 ≦.079 | ― | 0.03 .001 | 300 – 600 – 1000 980 – 1970 – 3280 | DRY |

| 10 3/8 | ≦2.5 ≦.098 | ― | 0.03 .001 | ||||

| 12 1/2 | ≦3.0 ≦.118 | ― | 0.03 .001 | ||||

| 16 5/8 | ≦4.0 ≦.157 | ― | 0.03 .001 | ||||

| 6/8 | 8 .315 | ≦1.2 ≦.048 | ― | 0.03 .001 | 300 – 600 – 1000 980 – 1970 – 3280 | DRY | |

| 10 3/8 | ≦1.5 ≦.059 | ― | 0.03 .001 | ||||

| 12 1/2 | ≦1.8 ≦.071 | ― | 0.03 .001 | ||||

| 16 5/8 | ≦2.4 ≦.094 | ― | 0.03 .001 | ||||

| 20 3/4 | ≦2.9 ≦.114 | ― | 0.03 .001 |

For more information about this product, visit our online e-catalog, or download the catalog/product report