For front turning operations | Swiss CNC Lathes

Swiss CNC Lathe front turning operations

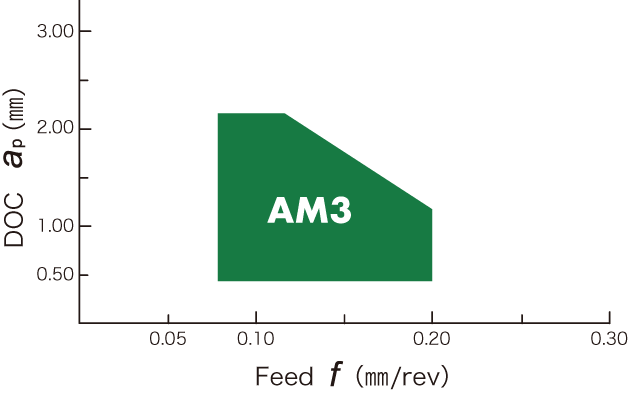

① AM3 designed for a wide range of machining from medium to light depths of cut

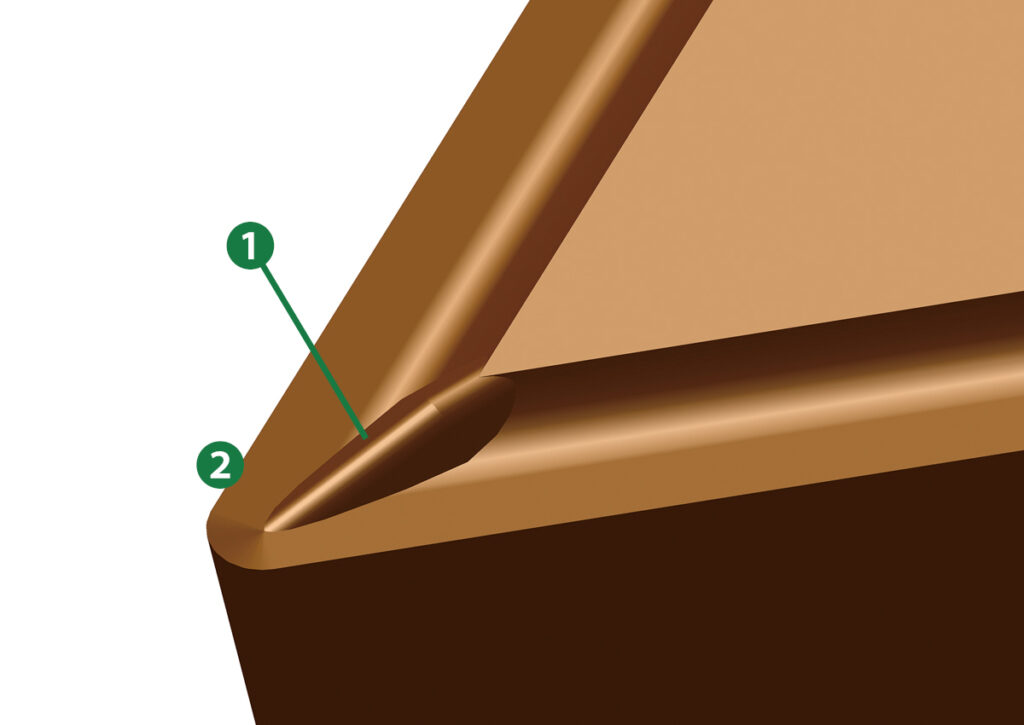

② Sharp cutting edge for shearing material

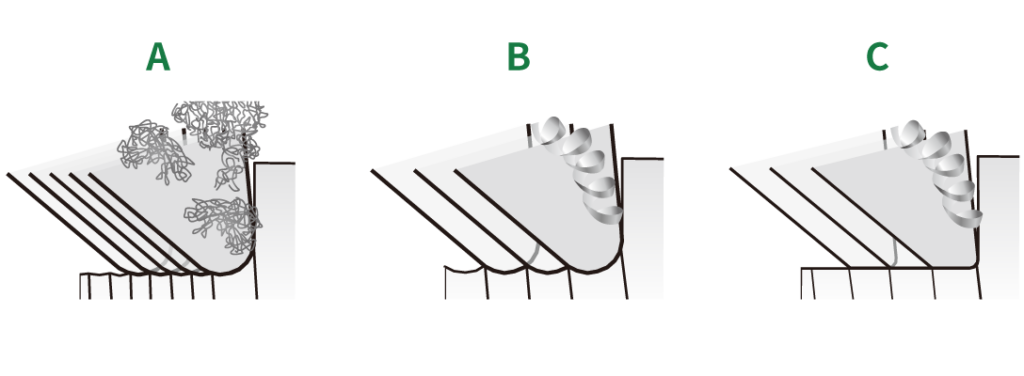

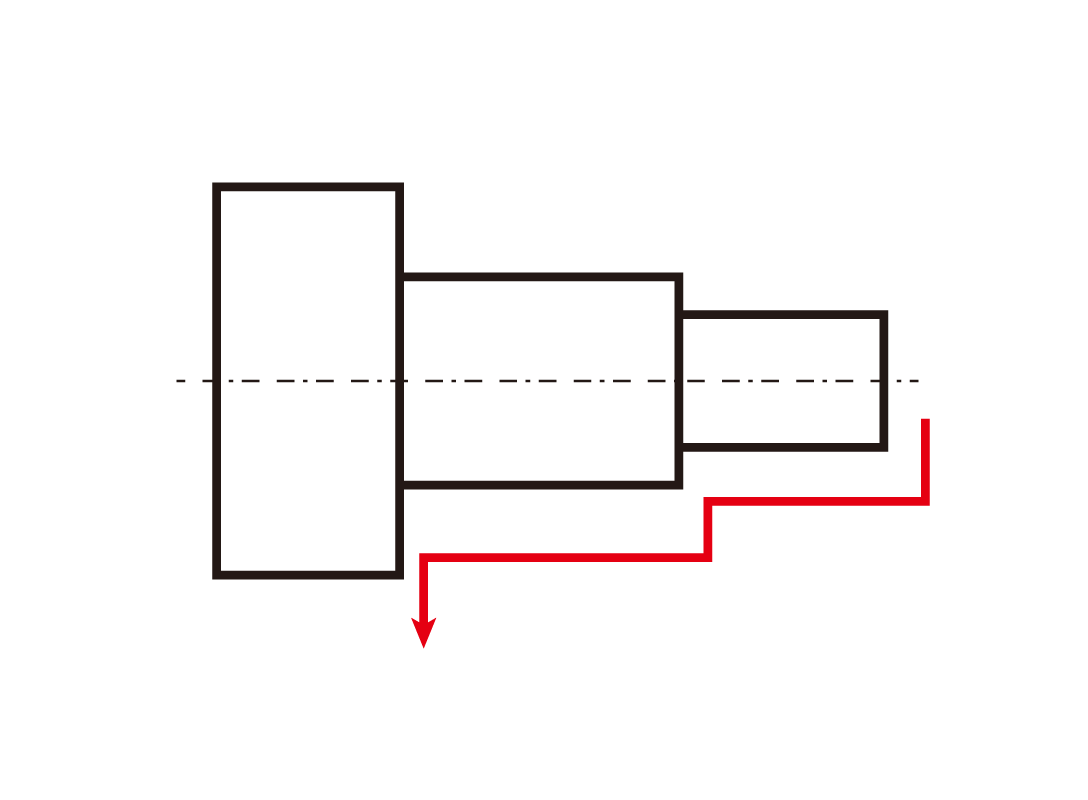

A. For conventional tools feed rate is reduced to maintain good surface finish which results in chip control issues.

B. If the feed rate is increased, the surface finish will deteriorate.

C. Inserts with a wiper help to maintain chip control and surface finishes even during high feed machining.

*when applying the DCGT… AM3-WP insert, use with our SDJC type holder (lead angle 93 degrees)

| Coated grade | Material | Operation type | Cutting speed (m/min) Cutting speed (SFM) | Feed (mm/rev) Feed (IPR) | DOC (mm) DOC (inch) |

|---|---|---|---|---|---|

| ST4 | Stainless | OD Turning continuous | 50 – 120 150 – 400 | 0.03 – 0.15 .0008 – .004 | 0.5 – 2.0 .020 – .118 |

| QM3 | Alloy steel / carbon steel / hardened material | ||||

| DM4/DT4 | Difficult-to-cut material / titanium alloy | 30 – 100 75 – 330 | |||

| TM4 | Non-ferrous / aluminum / plastic / general purpose | 50 – 120 150 – 600 |

| Front turning | |

|---|---|

|

|

|

|

|

|

|

|

|

|

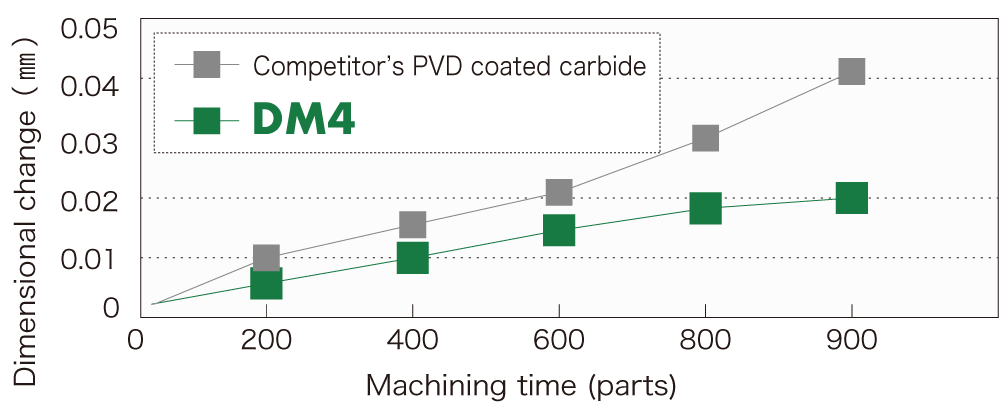

After running 900 parts, the competitor’s insert resulted in a dimensional change of 0.041mm .0016” while DM4 had better machining stability with parts showing dimensional change of only 0.02mm .0007” after the same amount of parts machined.

| Front turning | |

|---|---|

|

|

|

|

|

|

|

|

| DT4 TFD11FR05AM3 |

1,500 pcs / corner

|

| Conventional tool |

700 pcs / corner

|

The current tool resulted in a measured surface finish of Ry = 10.2μm with 500 parts machined and a 0.1mm .004” dimensional change from the start of production.

DT4 achieved dimensional consistency and machined 1000 parts all with surface finish of Ry 2.3 μm.

For more information about this product, visit our online e-catalog, or download the catalog/product report