For turning small parts | UC1 and Y axis holder + High-pressure coolant

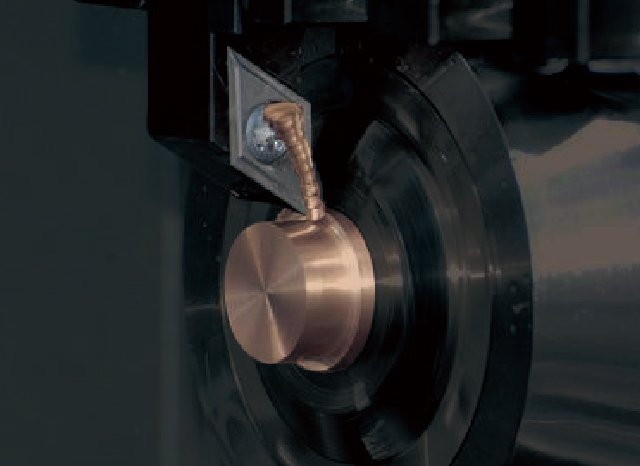

Pure copper (C1020/C1100) machined using Sliding head automatic lathes or CNC-lathes

Diamond-coated carbide: UC1 with excellent wear resistance & welding resistance is recommended because tooling tends to wear and the machined surface deteriorates due to welding, resulting in short tool life.

A good machined surface can be obtained by applying the appropriate cutting condition (low cutting depth/low feed) which reduces the chip thickness.

| Battery connector | |

|---|---|

|

C1100 ⌀10-20 ⌀.394 -.787 in. |

|

55 – 110 180 – 360 |

|

0.03 .0012 |

|

0.2 .008 |

|

WET |

| UC1 DCMT11T302 DCMT32.508 FNAM3 |

1000 pcs / corner

|

| PVD super coat DCGT11T302 DCMT32.508 molded chipbreaker | 50 pcs / corner |

| Electrode part | |

|---|---|

|

C1100 ⌀12 ⌀.472 in. |

|

80 262 |

|

0.05 .002 |

|

1.0 .040 |

|

WET |

| UC1 DCMT11T301 DCMT32.504 FNAM3 |

2000 pcs / corner

|

| PVD super coat DCGT11T301 DCMT32.504 molded chipbreaker | 100 pcs / corner |

[ Cutting conditions ]

Part material : C1100 vc=

80m/min ap=1.0mm

260 SFM ap=.040

WET

[ Tools used ]

DCMT11T302FNAM3

DCMT32.508FNAM3

UC1

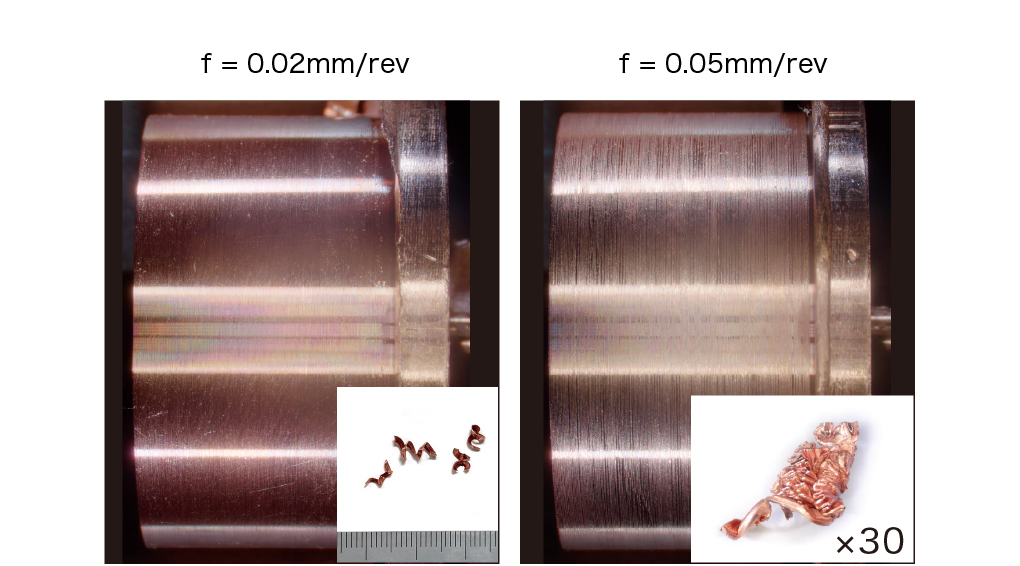

If the cutting conditions cause the chips to become thick (high cutting depth or high feed) then the machined surface will deteriorate due to chip clogging.

| Grade | Tool | Operation | Machining | Speed (m/min) Speed (SFM) | Feed (mm/rev) Feed (IPR) | DOC (mm) DOC (inch) | WET |

|---|---|---|---|---|---|---|---|

| UC1 | Tough pitch copper C1100 | Turning | Rough – Finish | 50 – 150 160 – 500 | 0.02 – 0.05 .0008 – .002 | 0.2 – 2.0 .008 – .080 | ● |

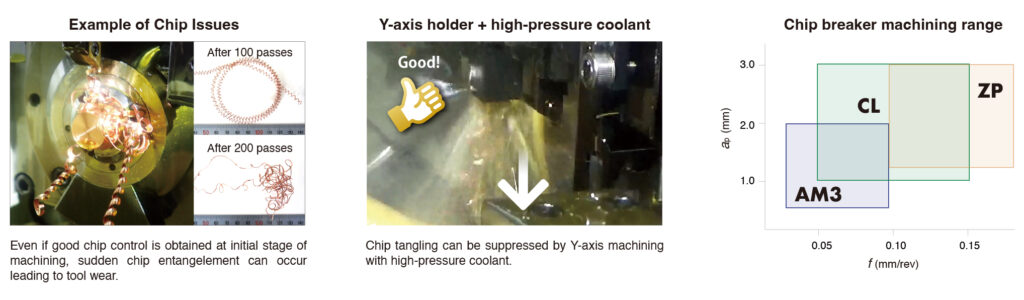

Using the cutting conditions shown, chips can be segmented and controlled with AM3 chipbreaker.

When machining at large depths of cut and high feed rate, select CL or ZP chipbreakers to suppress chip clogging.

Stable chip generation may be difficult with a chip breaker alone, it is recommended to add a Y-axis holder + high pressure coolant

| Grade | Tool | Operation | Machining | Speed (m/min) Speed (SFM) | Feed (mm/rev) Feed (IPR) | DOC (mm) DOC (inch) | WET |

|---|---|---|---|---|---|---|---|

| UC1 TM4 | Oxygen-free copper C1020 | Turning | Rough – Finish | 50 – 150 160 – 500 | 0.02 – 0.20 .0008 – .008 | 0.5 – 3.0 .020 – .118 | ● |

Refer to content above to select cutting conditions and chip breaker to obtain good chip control.

If you want longer tool life than PVD Carbide: TM4, use Diamond-Coated Carbide: UC1.

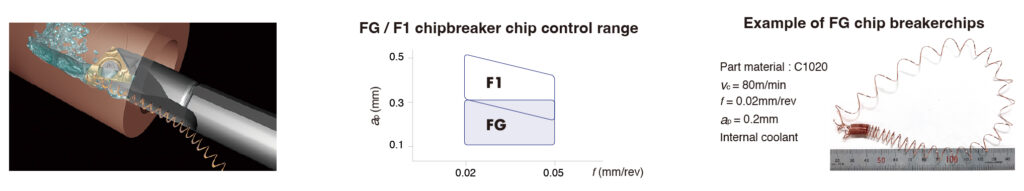

Improve chip control by using FG/F1 chip breakers to evacuates chips backwards and high-pressure coolant

| Grade | Tool | Operation | Machining | Speed (m/min) Speed (SFM) | Feed (mm/rev) Feed (IPR) | DOC (mm) DOC (inch) | WET |

|---|---|---|---|---|---|---|---|

| UC1 TM4 | C1100 C1020 | Turning | Finish | 50 – 150 160 – 500 | 0.02 – 0.05 .0008 – .002 | 0.1 – 0.5 .004 – .020 | ● |

If you want longer tool life than PVD Carbide: TM4, use Diamond-Coated Carbide: UC1.

For more information about this product, visit our online e-catalog, or download the catalog/product report