For front turning operations | Swiss CNC Lathes

Swiss CNC Lathe front turning operations

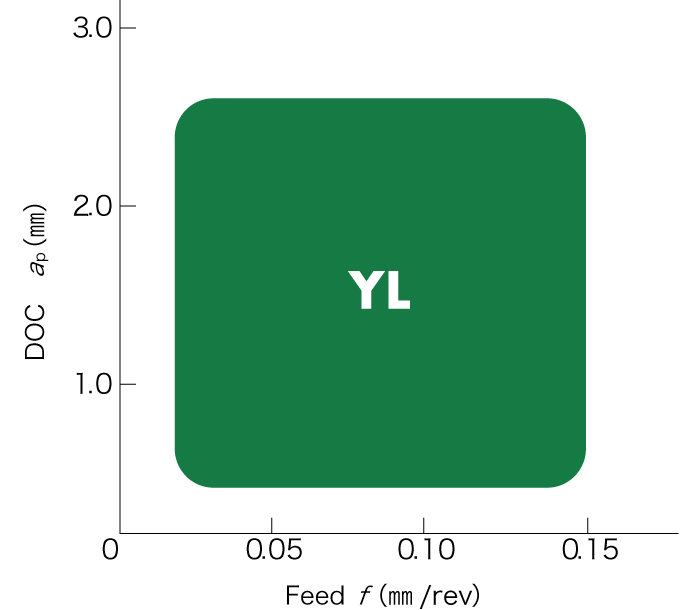

| Coated grade | Material | Operation type | Cutting speed (m/min) Cutting speed (SFM) | Feed (mm/rev) Feed(IPR) | DOC (mm) DOC (inch) |

|---|---|---|---|---|---|

| ST4 | Stainless | OD Turning continuous to interrupted | 50 – 120 150 – 400 | 0.03 – 0.15 .0008 – .004 | 0.3 – 2.5 .020 – .118 |

| QM3 | Alloy steel / carbon steel / hardened material | ||||

| DM4/DT4 | Difficult-to-cut material / titanium alloy / high temp alloys | 30 – 100 100 – 400 | |||

| TM4 | Non-ferrous / aluminum / plastic / general purpose | 50 – 180 150 – 600 |

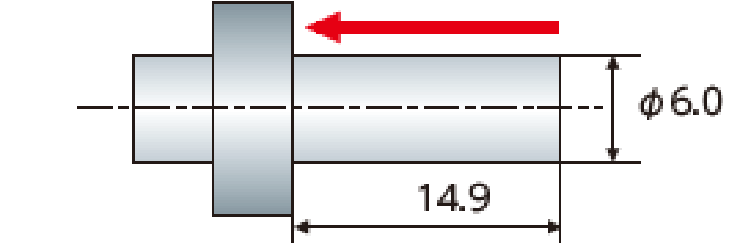

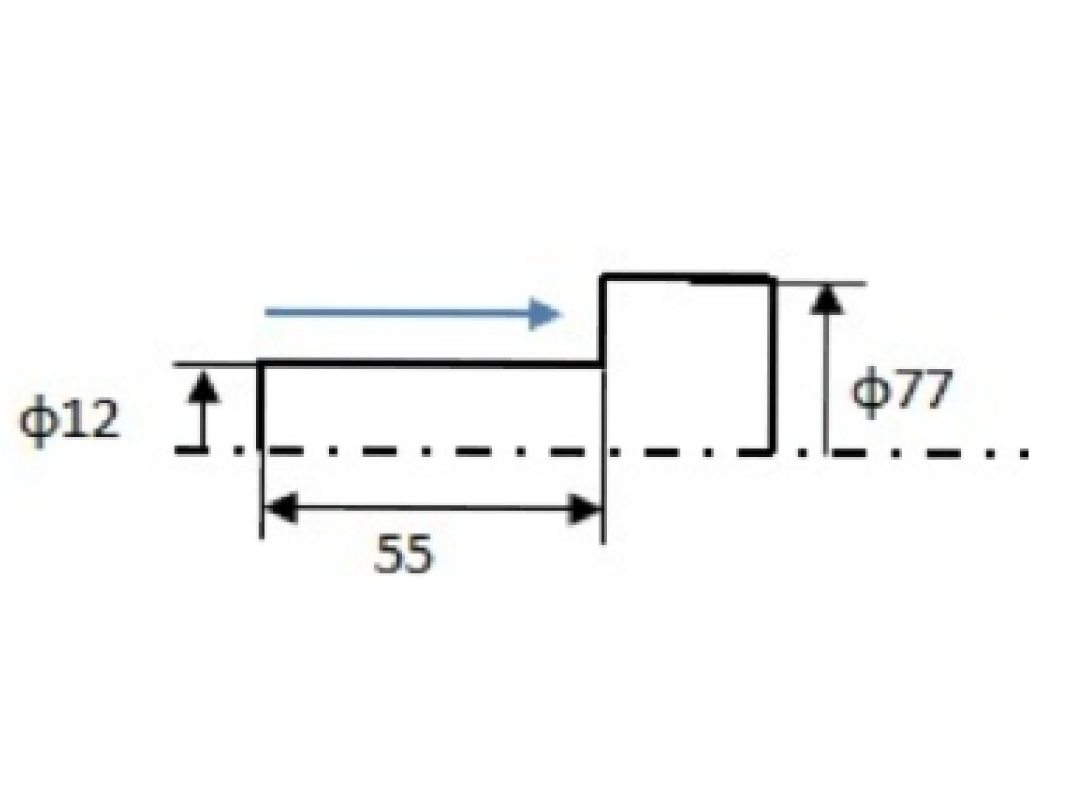

| Pin | |

|---|---|

|

|

|

|

|

|

|

|

|

|

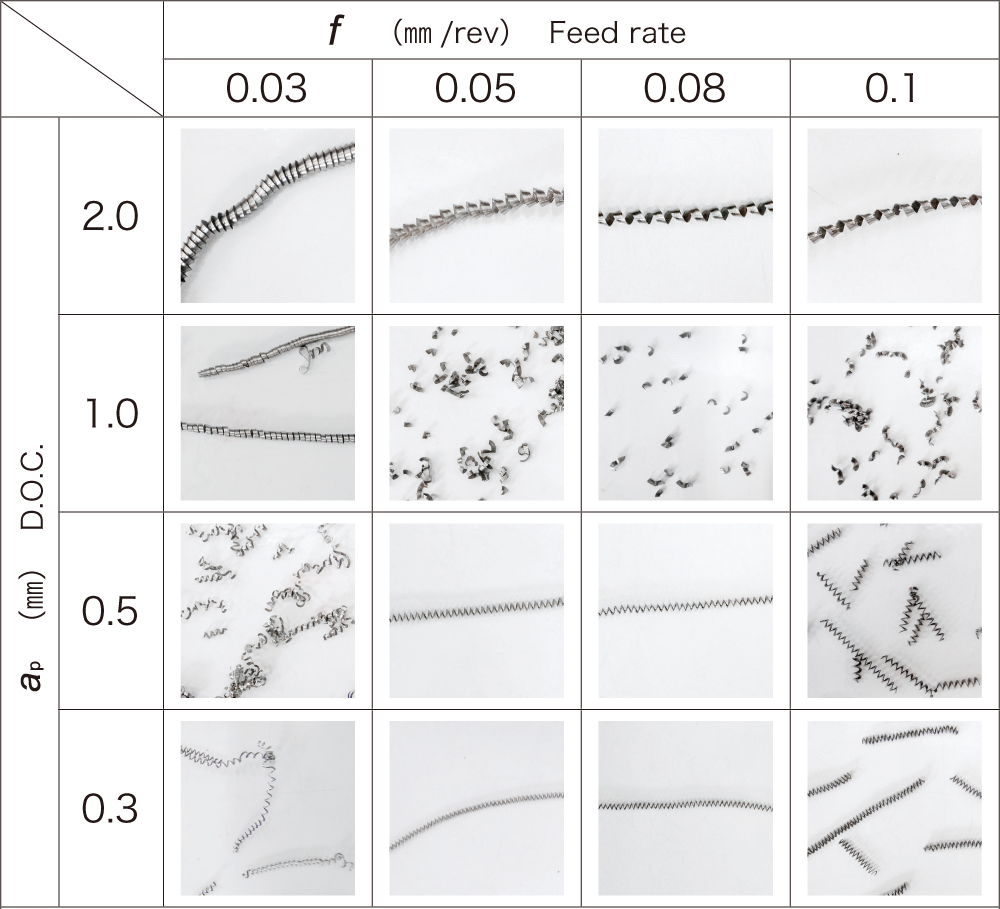

| YL chipbreaker |

3,000 pcs / corner

|

| Competitor’s (PVD coated carbide) |

2,000 pcs / corner

|

YL had good chip control and longer tool life than competitor’s conventional product. Also, achieved stable machining resulting in part dimensional consistancy.

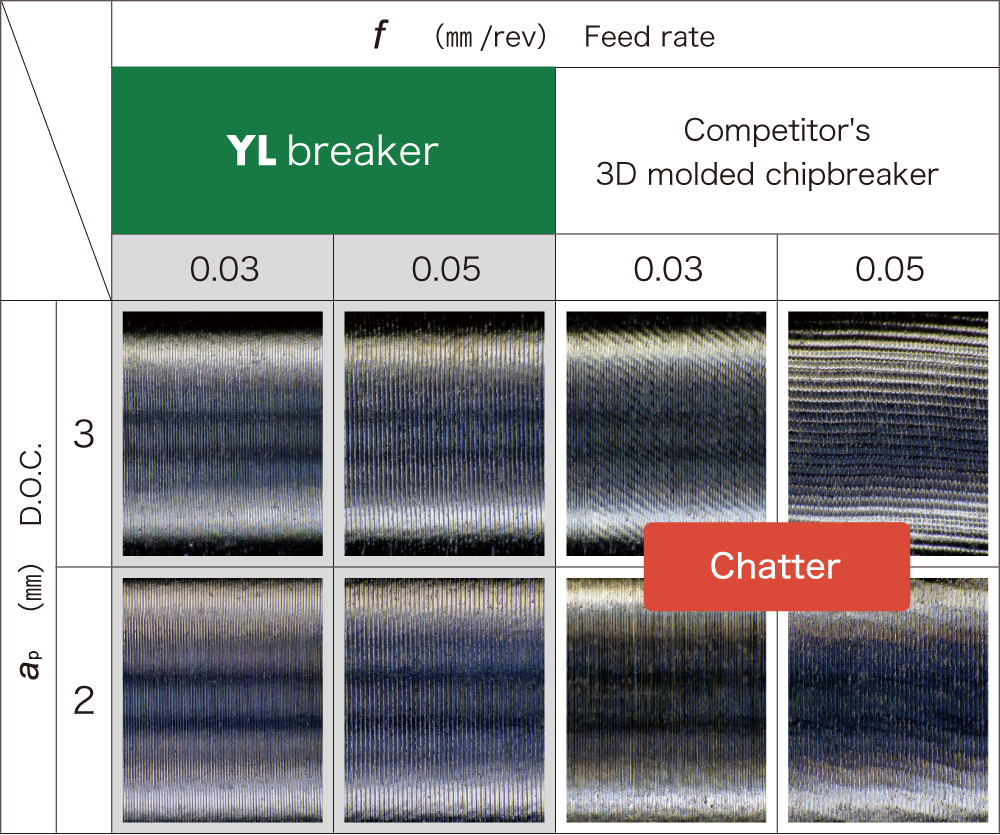

| Auto parts | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| YL chipbreaker + DM4 |

300 pcs / corner

|

| Competitor’s PVD coated carbide |

200 pcs / corner

|

YL achieved excellent chip control. Longer tool life and larger production run of parts with excellent surface finish compared to company’s current insert.

For more information about this product, visit our online e-catalog, or download the catalog/product report