Friction stir welding tool | NTK Ceramics

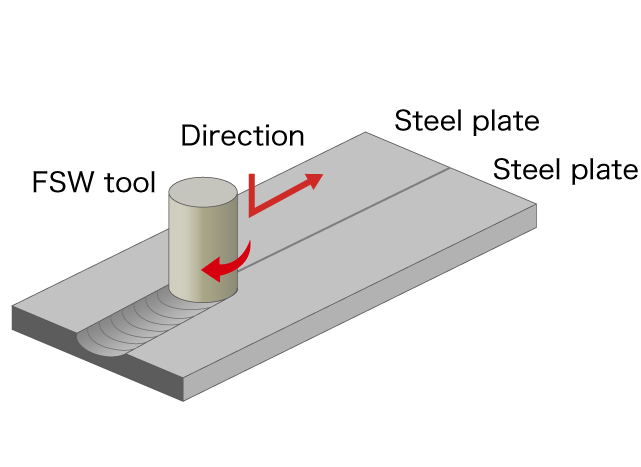

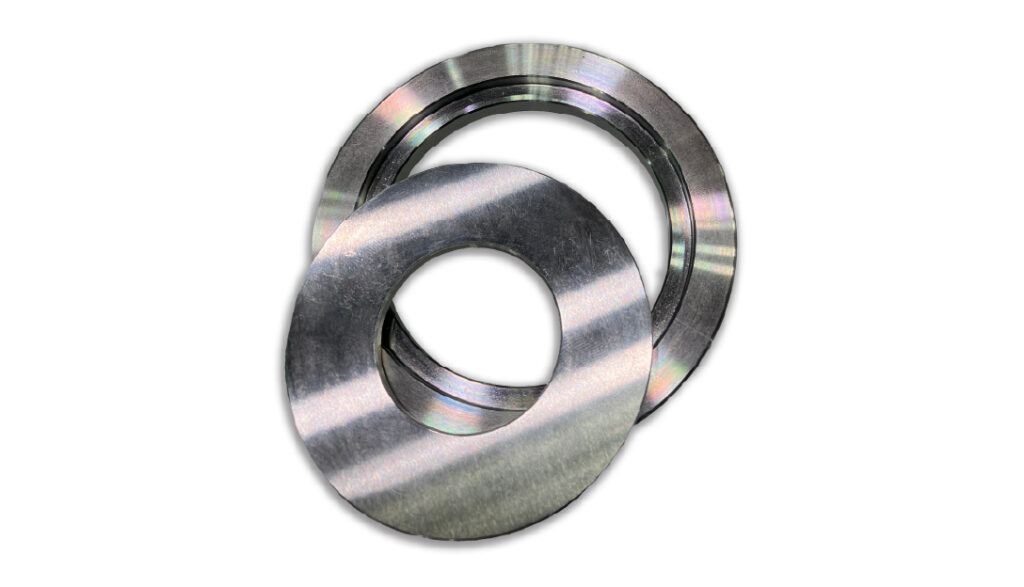

Friction Stir Welding (FSW) is a solid-phase welding technique developed in the UK in 1991. It uses a rotating cylindrical tool with a protruding tip to generate frictional heat, softening the material and enabling plastic flow for strong, deformation-resistant joints.

Unlike fusion welding, FSW does not melt the materials, reducing deformation, improving grain refinement, and maintaining joint strength. Additionally, it is more energy-efficient than traditional welding methods.

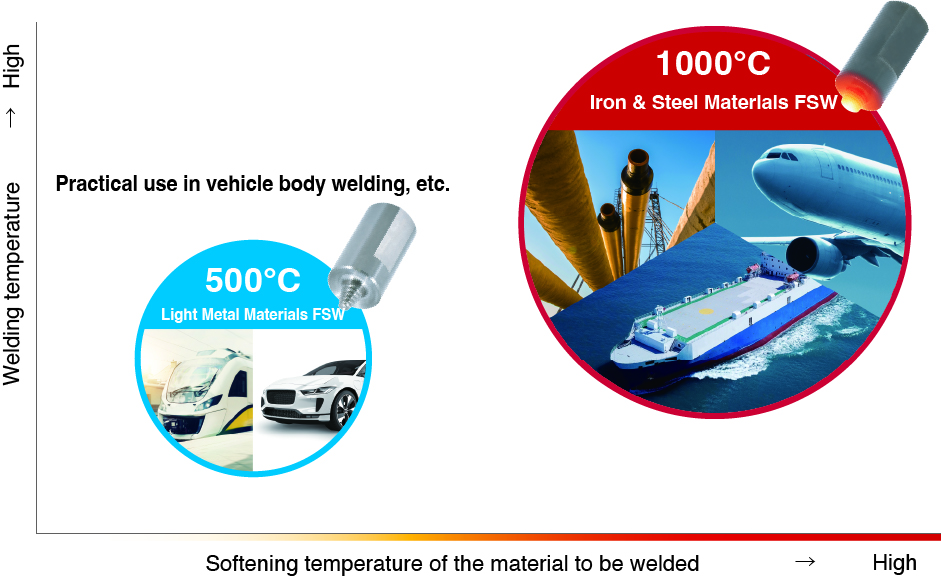

While welding technologies for aluminum alloys are advancing in vehicle manufacturing, iron/steel materials pose challenges due to their high softening temperatures and the limited availability of cost-effective, high-temperature-resistant tools.

NTK CUTTING TOOLS is driving progress in Friction Stir Welding (FSW) for these materials by utilizing its expertise in ceramic materials and advanced technologies.

| Tool life | Tool cost | |

|---|---|---|

| NTK Ceramics | ○ | ◎ |

| PcBN type | ◎ | × |

| Carbides | Processing not possible (tool melting) | |

| HSS | Processing not possible (tool melting) | |

*Ferrous metals: steel, stainless steel, copper

| Line Welding conditions guideline | Rotation speed(min-1) | 1000 – 2000 |

| Welding speed (mm/min) (SFM) | 1000 – 2000 3.3 – 6.6 |

| Tool Materials | High Strength SiAlON Ceramics |

| Fine particle cemented carbide | |

| Shank dia. | ⌀ 8, 10, 12, 16, 20mm .320, .400, .472, .630, 787inches*Availability larger than ⌀ 20 mm .787” is available, |

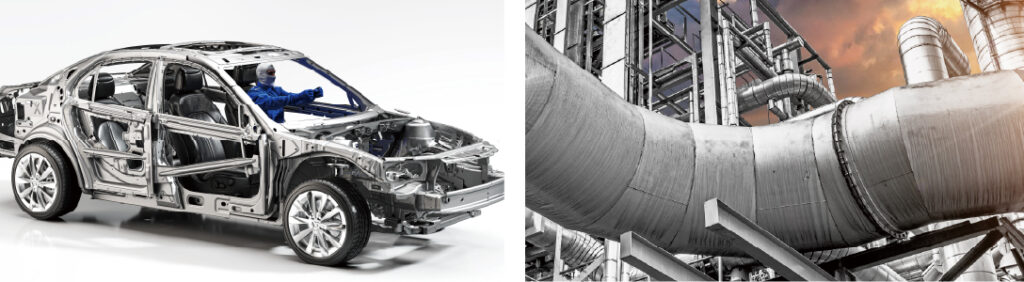

Previously, SUS was sprayed onto steel to improve surface performance. Can be easily joined by FSW

| High-tensile steel | ||

|---|---|---|

| Welding method | Line welding | |

| Welding material | Material | SPFC980 ( High-tensile980MPa ) |

| Thickness (mm) (inch) | 1.2 .047 | |

| Tool shape | Shank Dia. (mm) (inch) | ⌀ 6 .236 |

| Shoulder Dia. (mm) (inch) | ⌀ 6 .236 | |

| Probe Dia. (mm) (inch) | ⌀ 3 .120 | |

| Probe length (mm) (inch) | 0.9 .035 | |

| Welding conditions | Rotation speed (min-1) | 1000 |

| Welding speed (mm/min) (SFM) | 100 .328 | |

| Welding distance (mm) (inch) | 850 33.5 | |

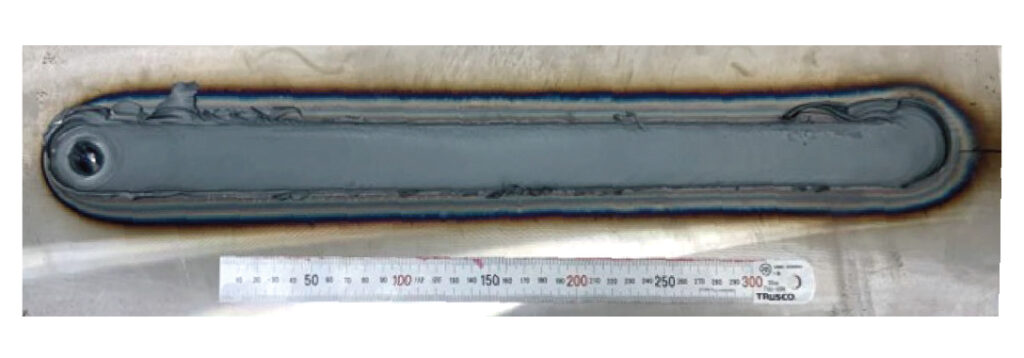

| Thick steel plate | ||

|---|---|---|

| Welding method | Line welding | |

| Welding material | Material | Low carbon steel |

| Thickness (mm) (inch) | 15 .60 | |

| Tool shape | Shank Dia. (mm) (inch) | ⌀ 37.5 1.48 |

| Shoulder Dia. (mm) (inch) | ⌀ 37.5 1.48 | |

| Probe Dia. (mm) (inch) | ⌀ 18.5 .728 | |

| Probe length (mm) (inch) | 14.7 .579 | |

| Welding conditions | Rotation speed (min-1) | 200 |

| Welding speed (mm/min) (SFM) | 50 .164 | |

| Welding distance (mm) (inch) | 500 19.7 | |

Before Welding

Conventional method – Welding

FSW (friction stir welding)

Joining without melting the base material, with minimal post-Welding deformation.

For more information about this product, visit our online e-catalog, or download the catalog/product report