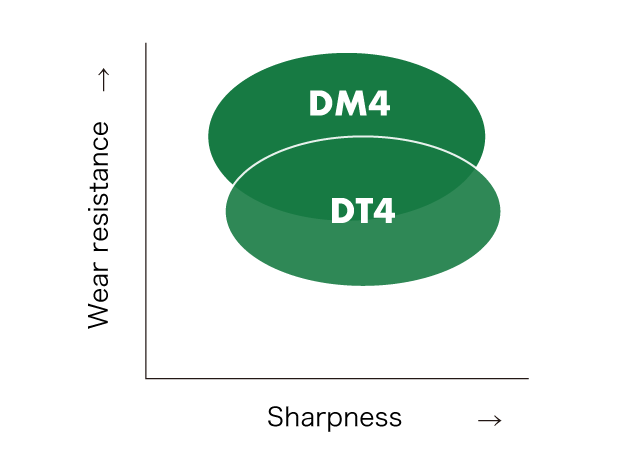

Difficult-to-cut materials | Carbide grade for Swiss CNC lathes

Difficult-to-cut materials especially heat resistant alloys and titanium alloys

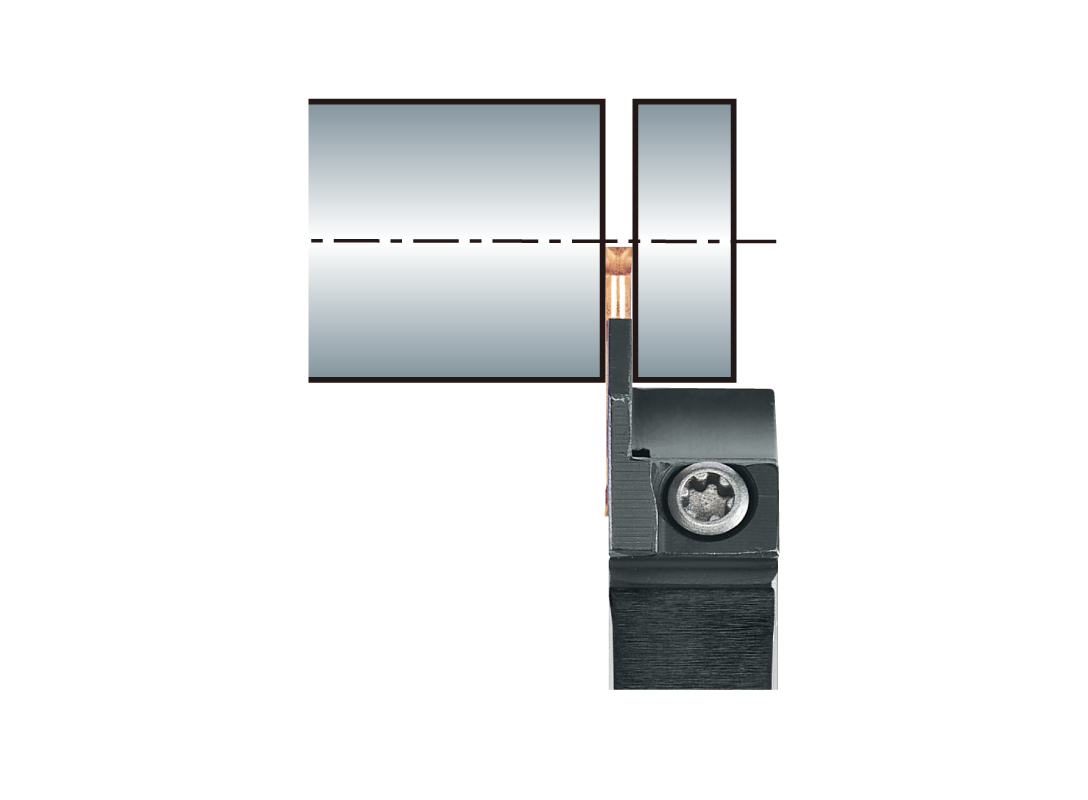

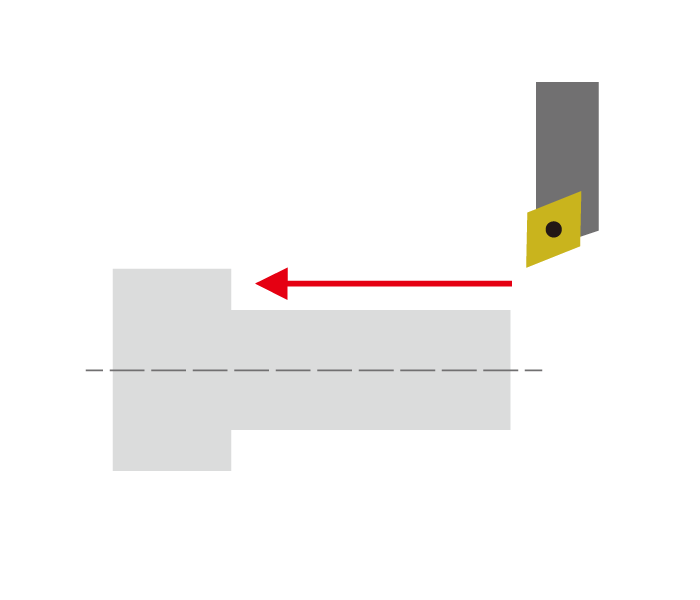

Front turning / Back turning / Grooving / Cut off

| Cut off | |

|---|---|

|

|

|

|

|

|

|

|

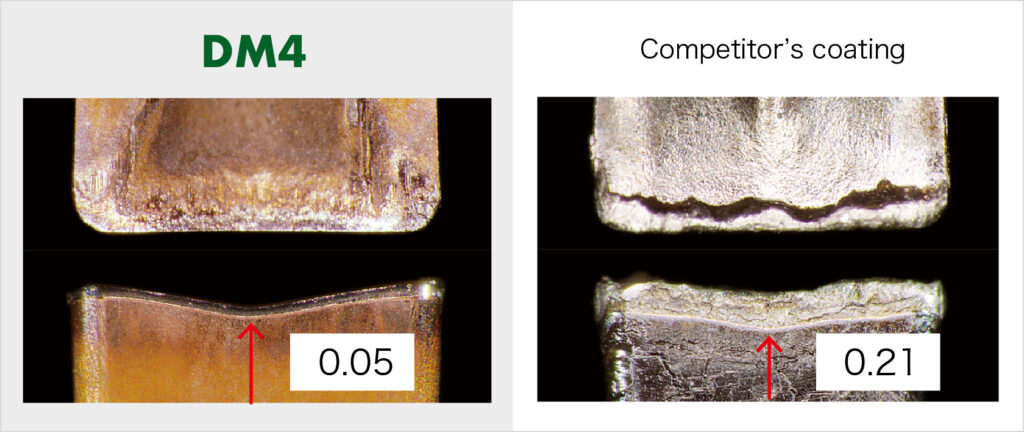

Insert edge comparison after 800 parts

DM4 exhibits excellent wear resistance compared to competitor’s insert.

| Aircraft parts | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| DM4 |

50 pcs / corner

|

| Competitor’s PVD coated carbide |

30 pcs / corner

|

DM4 achieved 1.7 times longer tool life compared to the competitor’s PVD coated carbide.

| Medical screw | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| DT4 |

400 pcs / corner

|

| Competitor’s PVD coated carbide |

250 pcs / corner

|

DM4 achieved 1.6 times longer life compared to the competitor’s insert.

For more information about this product, visit our online e-catalog, or download the catalog/product report