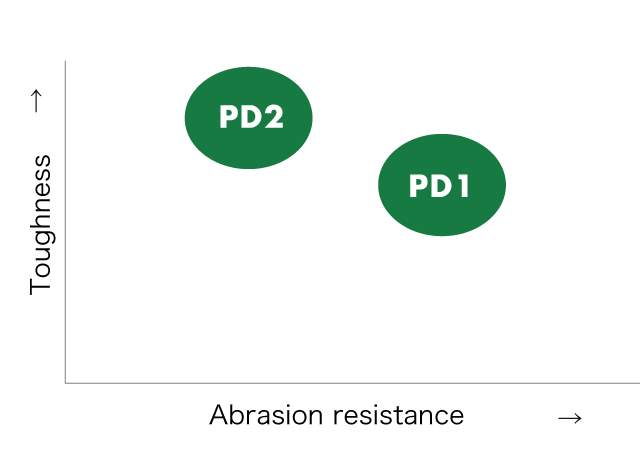

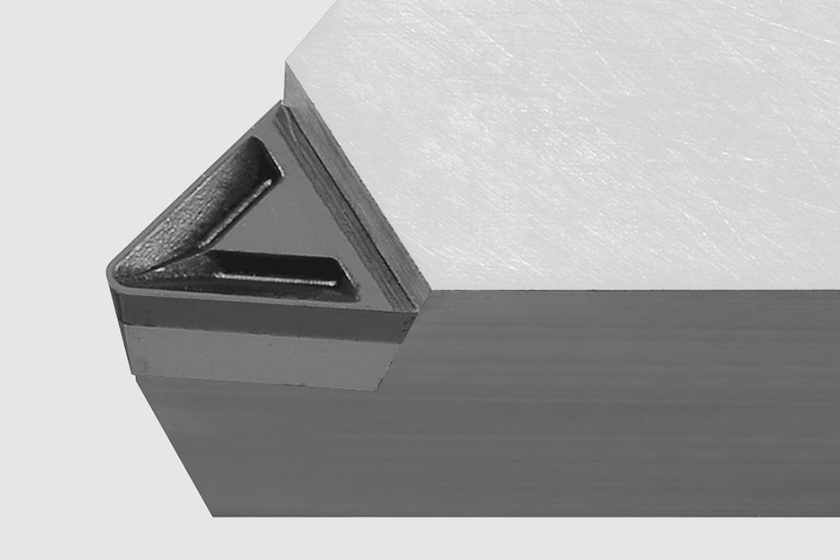

Non-ferrous material machining | PCD grades for Swiss CNC lathes

Non-ferrous machining such as aluminum, brass, resin, copper, carbon, ceramics

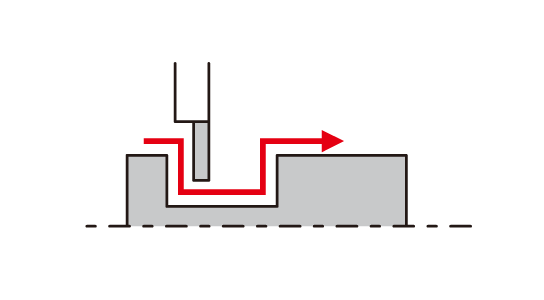

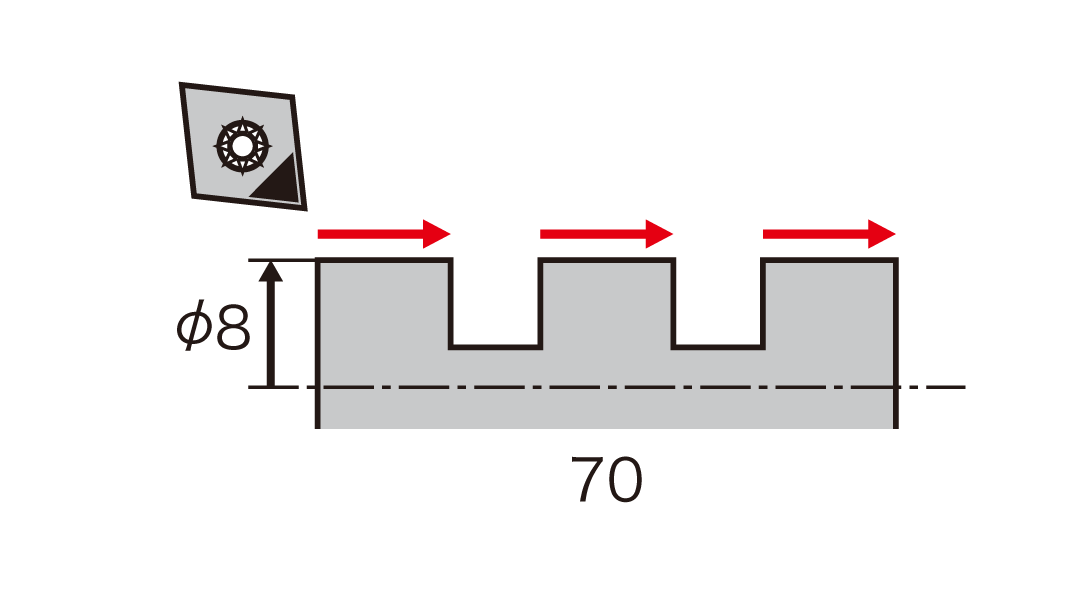

Front turning / Back turning / Grooving

| Spool | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| PD1 |

10,000 pcs / corner

|

| Competitor’s brazed carbide insert | 1,000 pcs / corner |

PD1 shortened cycle time on this single pass operation and performed well with no issue of BUE resulting in a good surface finish.

| Spool | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| PD2 |

10,000 pcs / corner

|

| Competitor’s PVD |

5,000 pcs / corner

|

PD2 doubled the productivity with its superior wear resistance compared to the competitor’s PCD.

For more information about this product, visit our online e-catalog, or download the catalog/product report