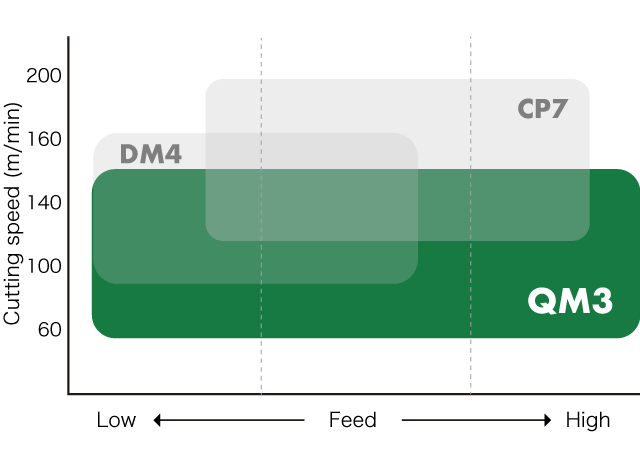

Carbon steel / Alloy steel machining | Carbide grade for Swiss CNC lathes

For Carbon steel and Alloy steel

Front turning / Back turning / Grooving / ID boring / Threading / Cut off

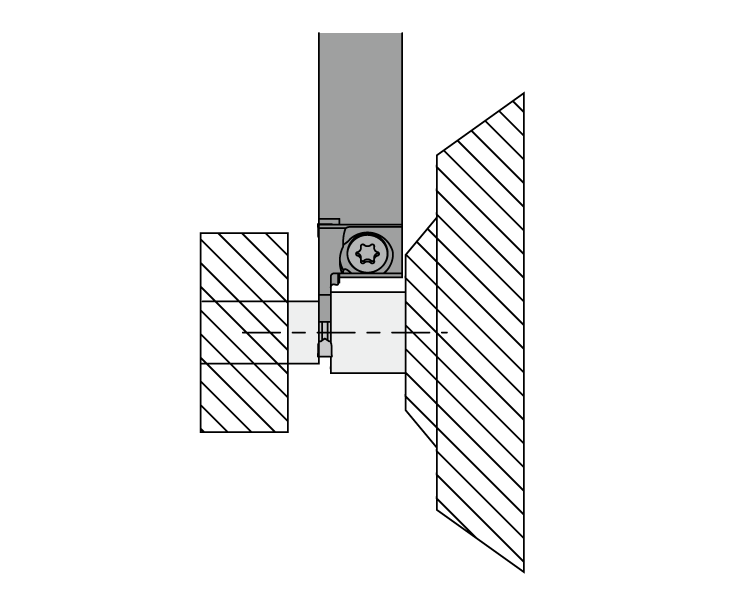

| Shaft Cut-off operation | |

|---|---|

|

|

|

|

|

|

|

|

| QM3 |

6,000 pcs / corner

|

| Competitor’s PVD coated |

3,000 pcs / corner

|

QM3 achieved twice the tool life compared to the competitor while maintaining good part surface quality.

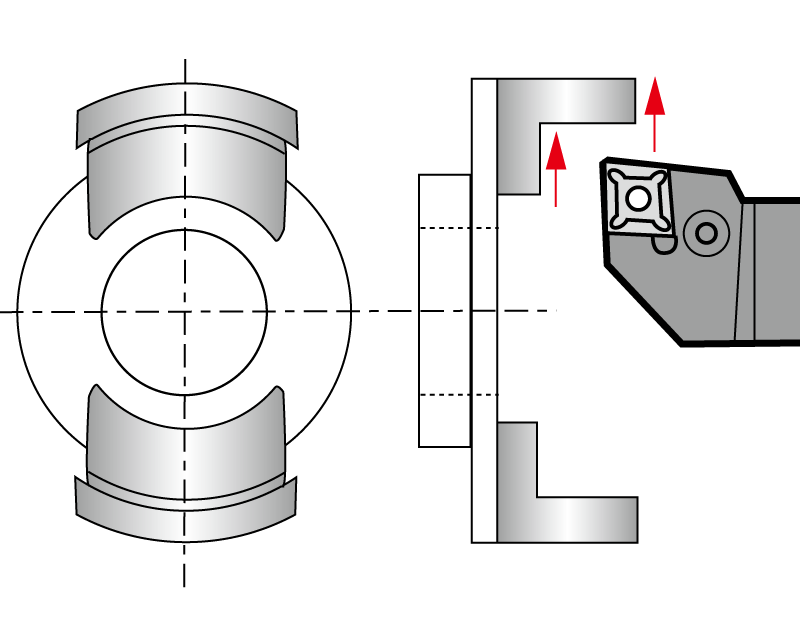

| Flange machining | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| QM3 |

120 pcs / corner

|

| Competitor’s CVD coated carbide |

45pcs / corner

|

Competitor’s insert had a problem with varying tool life.

QM3 with Z5 chipbreaker achieved 2.5 times longer tool life.

For more information about this product, visit our online e-catalog, or download the catalog/product report