Multifuntioning tool for machining non-ferrous material| Swiss CNC Lathes

2 grades to choose from for machining needs

PD1 – PCD grade

KM1 – carbide grade

| Coated grade | Material | Operation type | Cutting speed (m/min) Cutting speed (SFM) | Groove width (mm) Groove width (inch) | Grooving feed rate(mm/rev) Grooving feed rate(IPR) | Side turning feed(mm/rev) Side turning feed(IPR) |

|---|---|---|---|---|---|---|

| PD1(PCD grade) | Non-ferrous / aluminum | Grooving / Side turning | 100 – 300 330 – 1000 | 2.0 – 2.5 .079 – .098 | 0.05 – 0.15 .002 – .008 | 0.03 – 0.10 .004 – .008 |

| KM1(Uncoated carbide grade) | 50 – 200 160 – 650 |

| Spool | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| KM1 |

300 pcs

|

| Competitor’s PVD coated carbide |

200 pcs

|

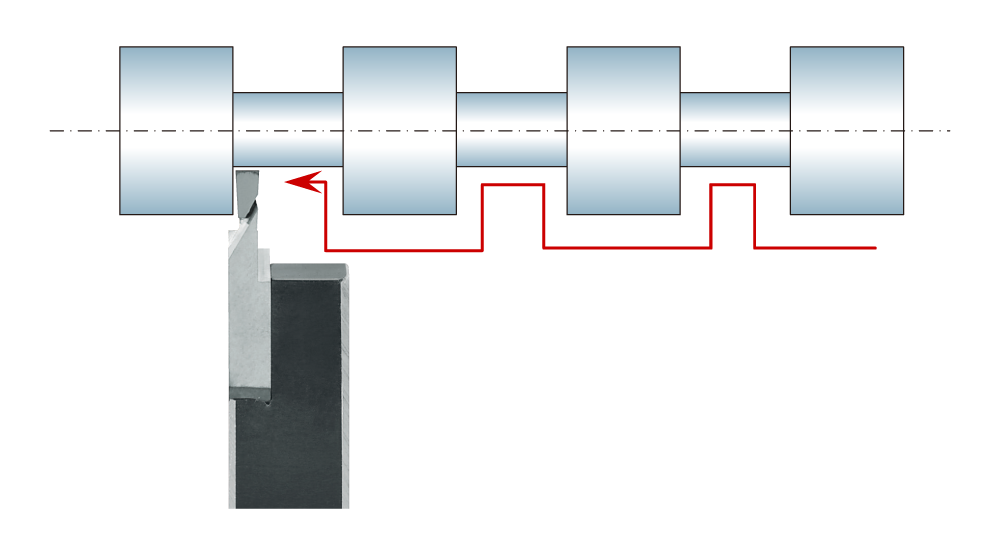

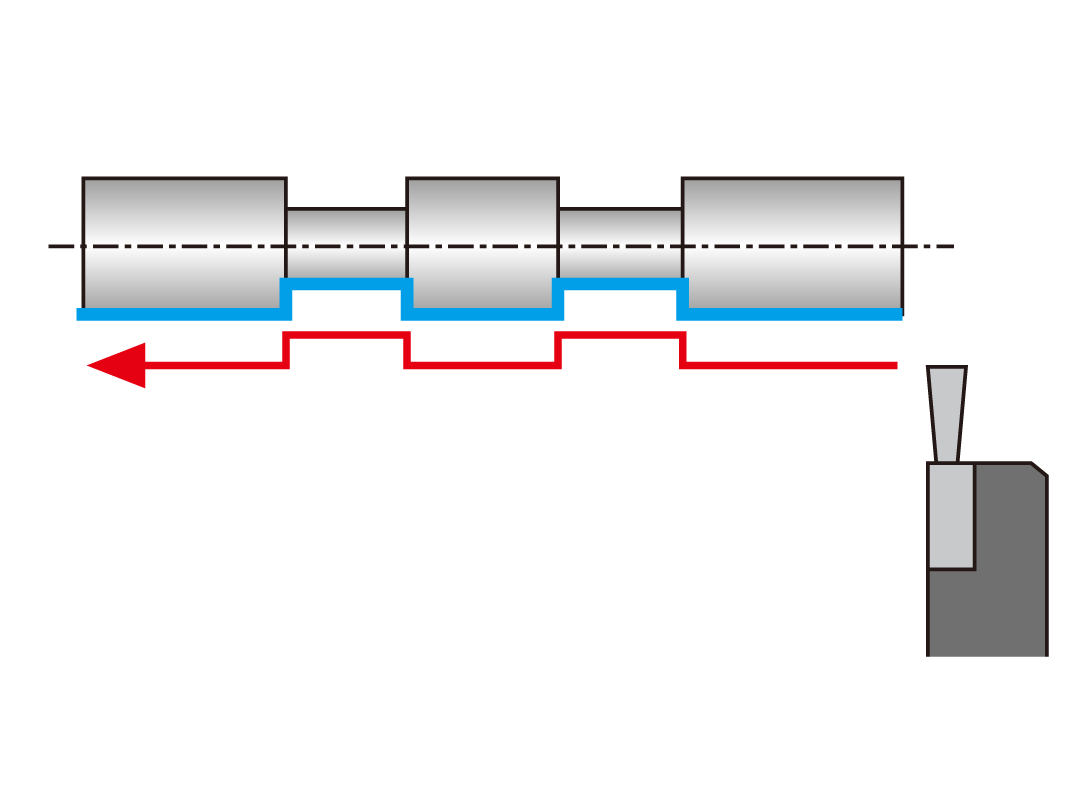

Competitor’s product required 3 grooving passes and inserts were often chipped and damaged. Cycle time was over 3 minutes.

NTK’s KM1 insert machined part in one pass reducing the cycle time to 1 minute 50 seconds.

| Spool | |

|---|---|

|

|

|

|

|

|

|

|

| PD1 |

10,000 pcs

|

| Competitor’s brazed carbide insert | 1,000 pcs |

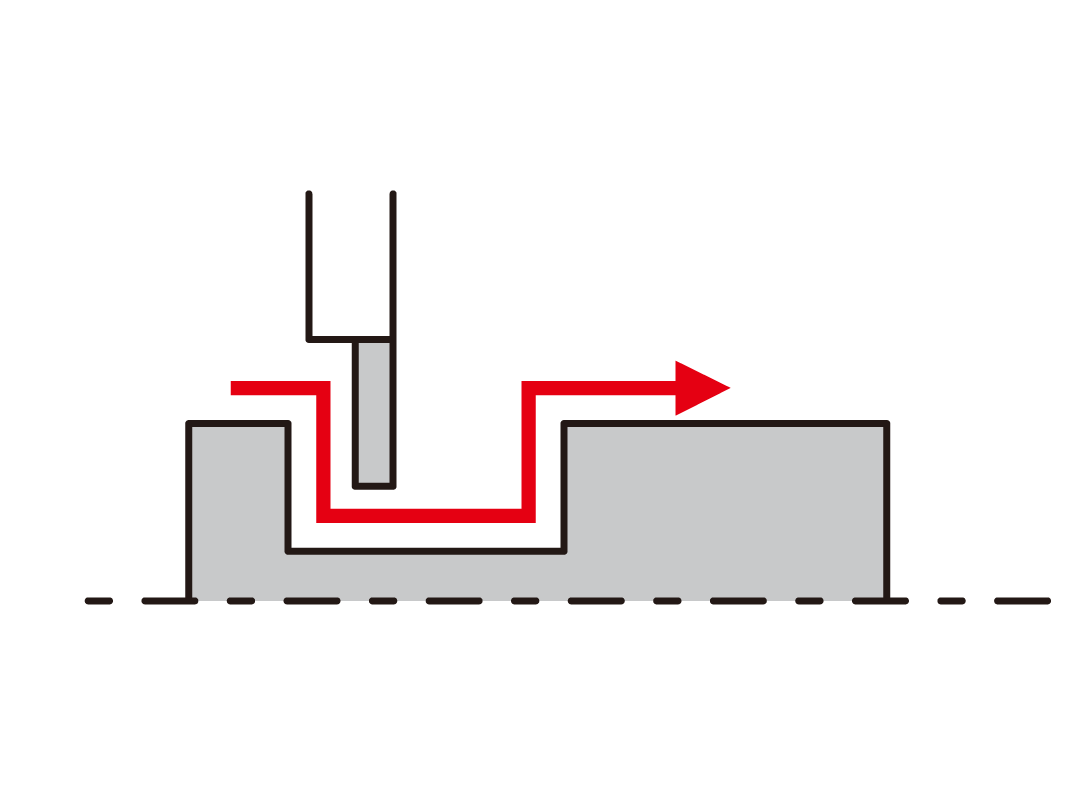

The GX insert solved the issue of chips remaining in the groove which eliminated an inspection process.

For more information about this product, visit our online e-catalog, or download the catalog/product report