For grooving| Swiss CNC lathes / Conventional CNC lathes

Swiss CNC lathes

Grooving and Side turning

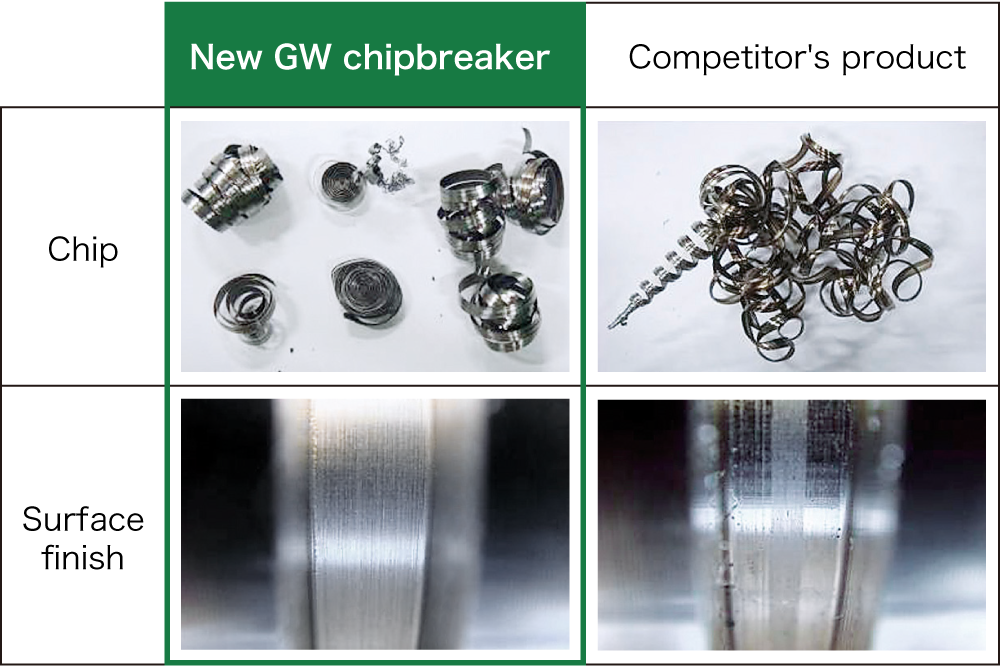

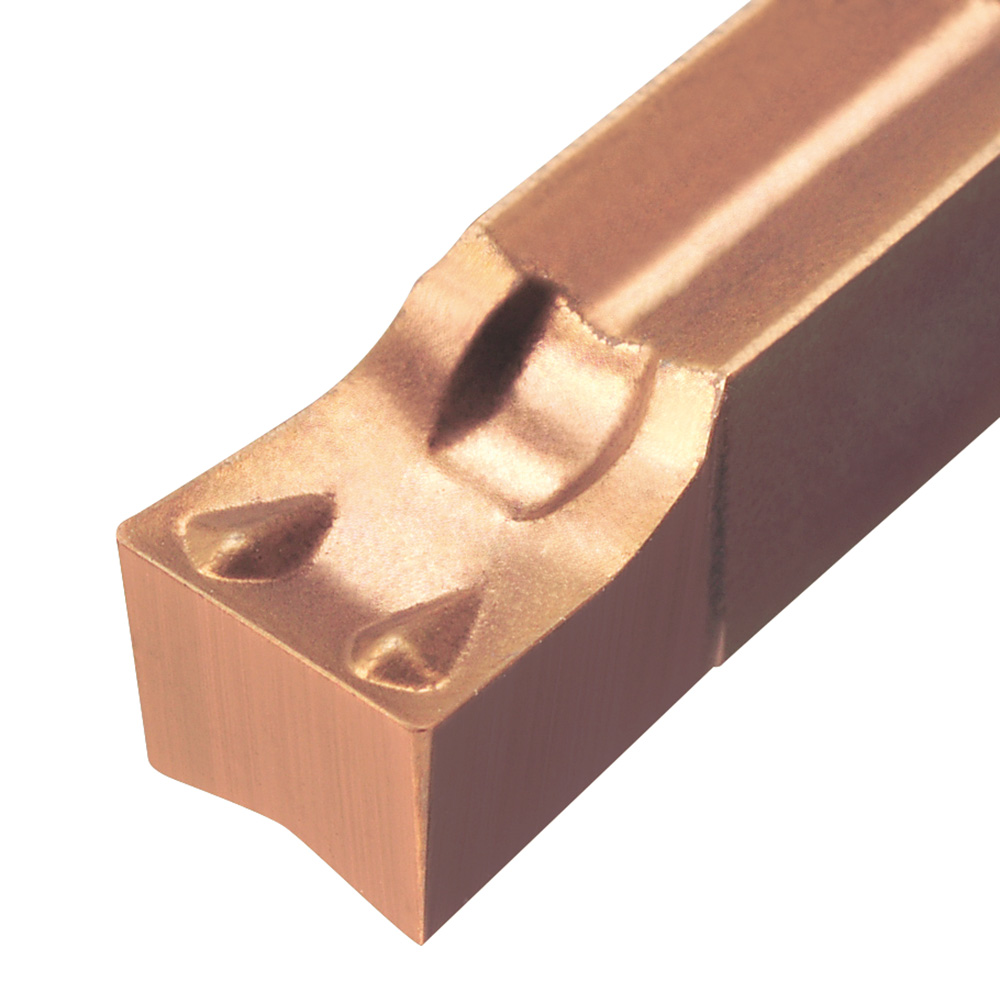

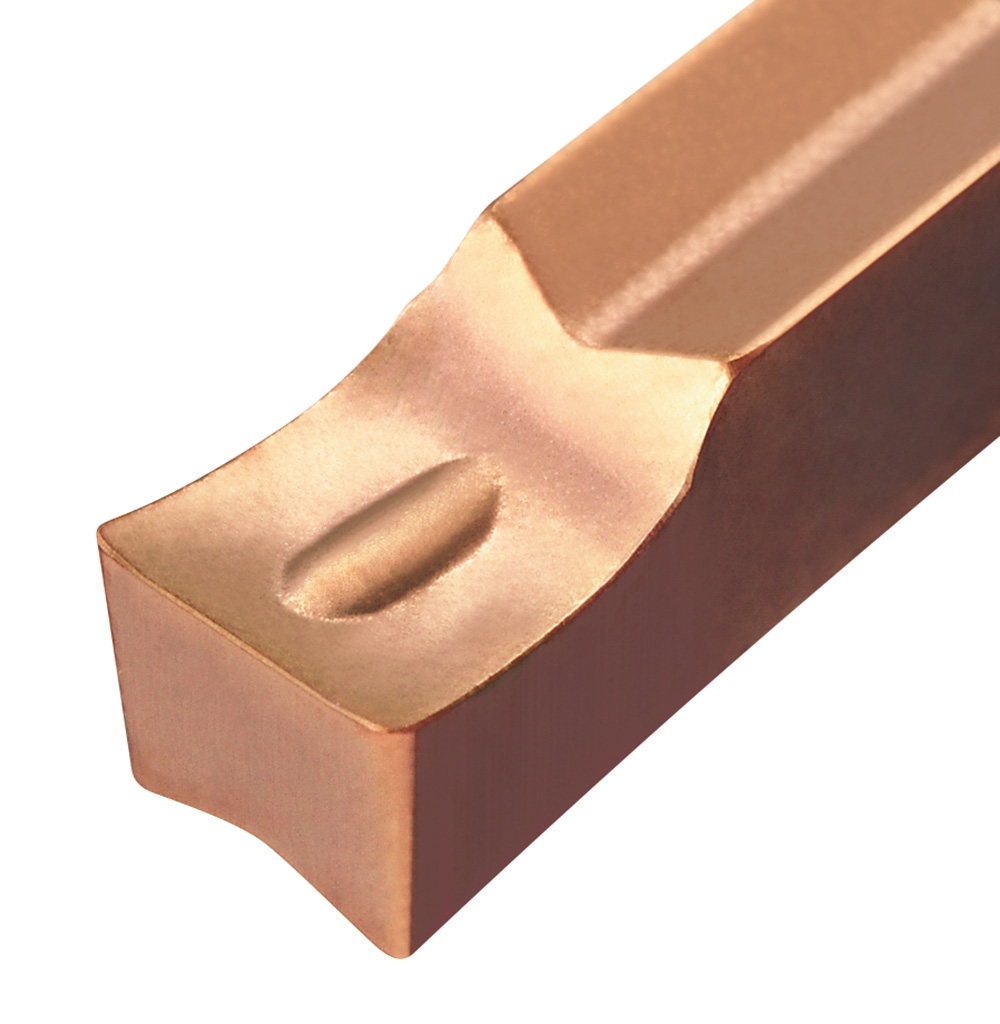

GW chipbreaker

A versatile design with edge sharpness and chip control features.

Multi-functional for grooving and side turning

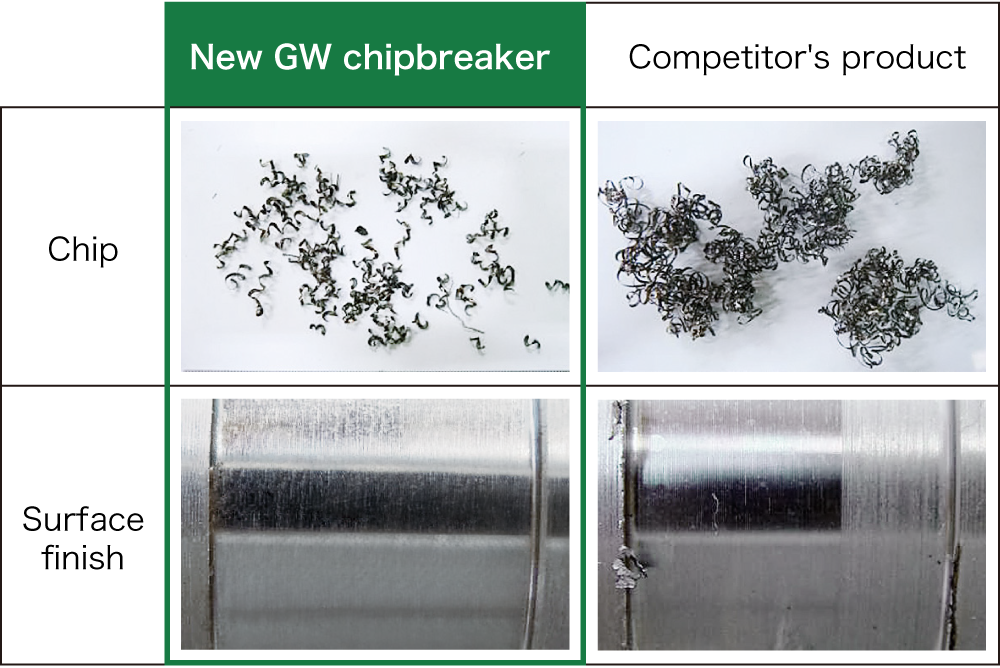

GV chipbreaker

Features superior sharpness with high rake face Ideal for applications requiring low tool pressure

Chip comparison (grooving)

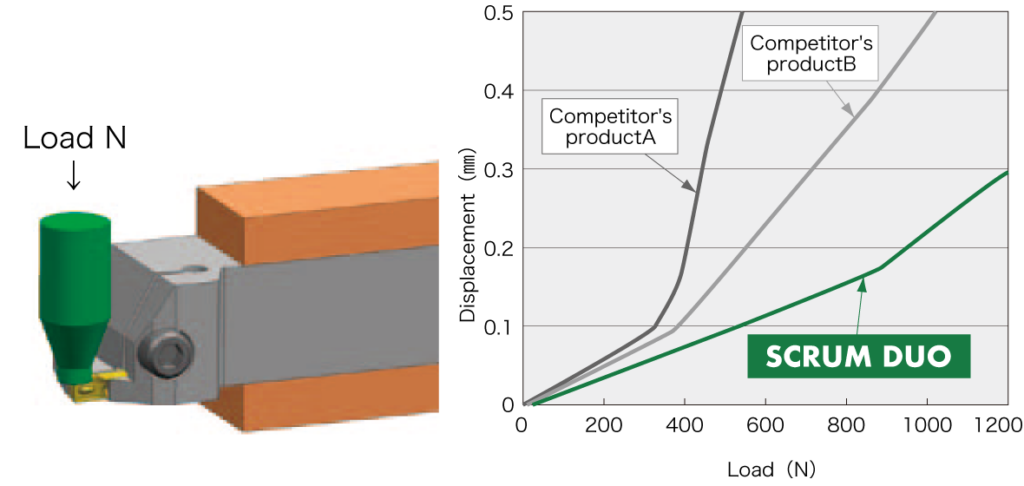

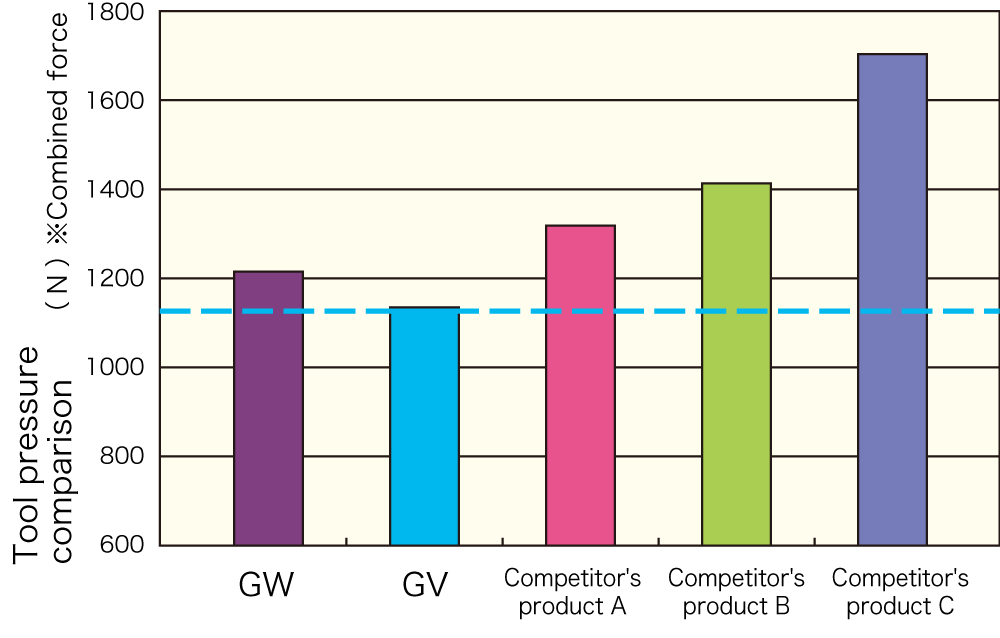

Tool pressure comparison (grooving)

| Coated grade | Material | Operation type | Cutting speed (m/min) Cutting speed (SFM) | Groove width (mm) Groove width (inch) | Grooving feed rate(mm/rev) Grooving feed rate(IPR) | Side turning feed(mm/rev) Side turning feed(IPR) ※ GW chipbreaker only |

|---|---|---|---|---|---|---|

| DM4 | Difficult-to-cut material / titanium alloy / Alloy steel / carbon steel / hardened material / general purpose / high temp alloys | Grooving | 30 – 180 75 – 600 | 3.0 – 4.0 .118 – .157 | 0.05 – 0.12 .002 – .006 | 0.03 – 0.10 .001 – .004 |

| 4.0 – 5.0 .157 – .197 | 0.08 – 0.15 .004 – .008 | 0.03 – 0.13 .006 – .012 | ||||

| 5.0 – 6.0 .197 – .236 | 0.12 – 0.16 .006 – .012 | 0.03 – 0.13 … |

For more information about this product, visit our online e-catalog, or download the catalog/product report