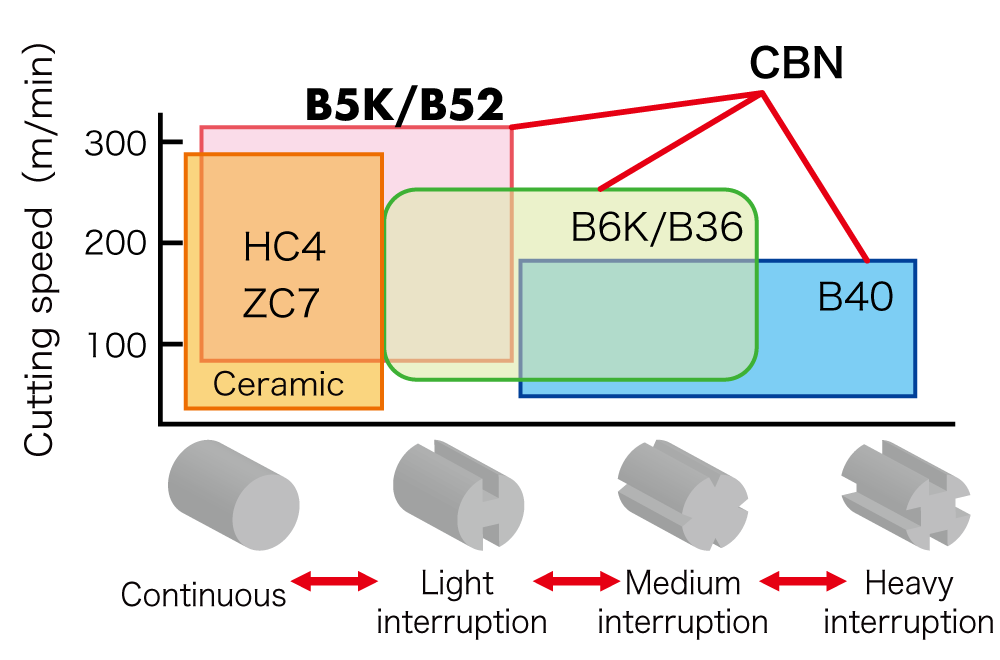

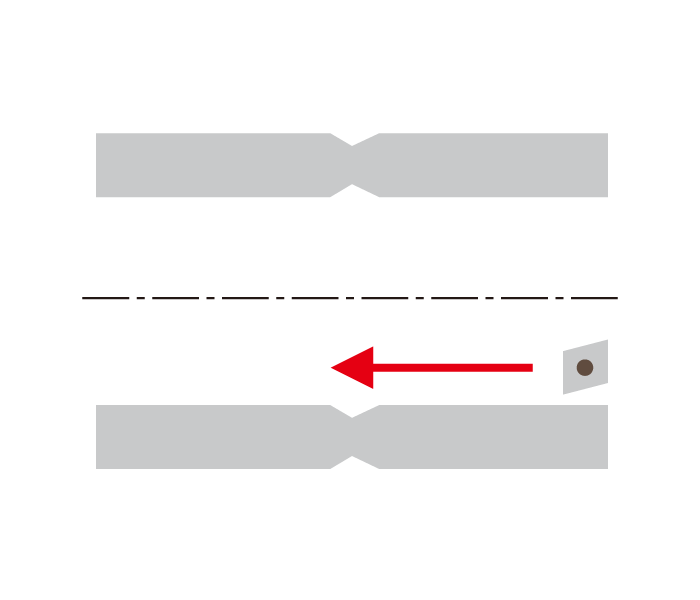

For continuous-light interruption machining | CBN for machining hardened material

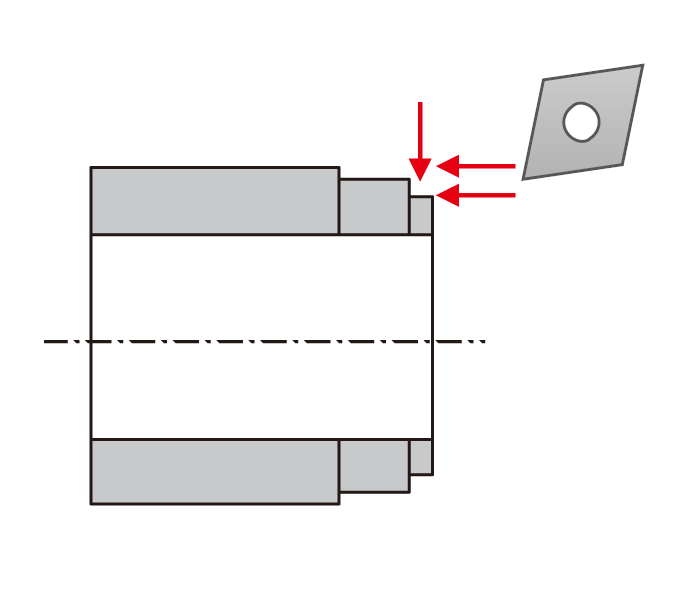

Continuous operations for hardened material at HRC55 or above

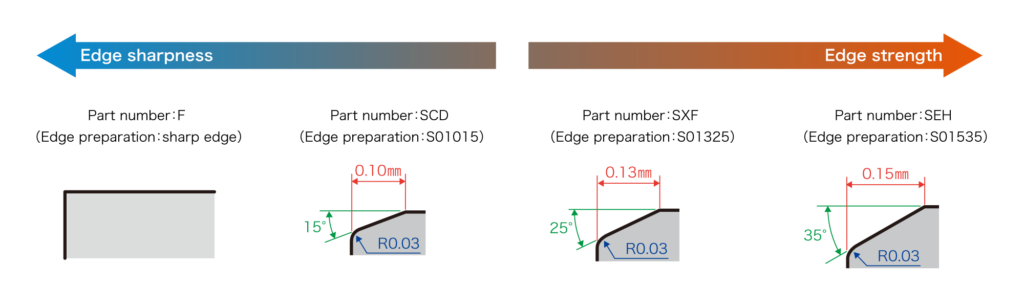

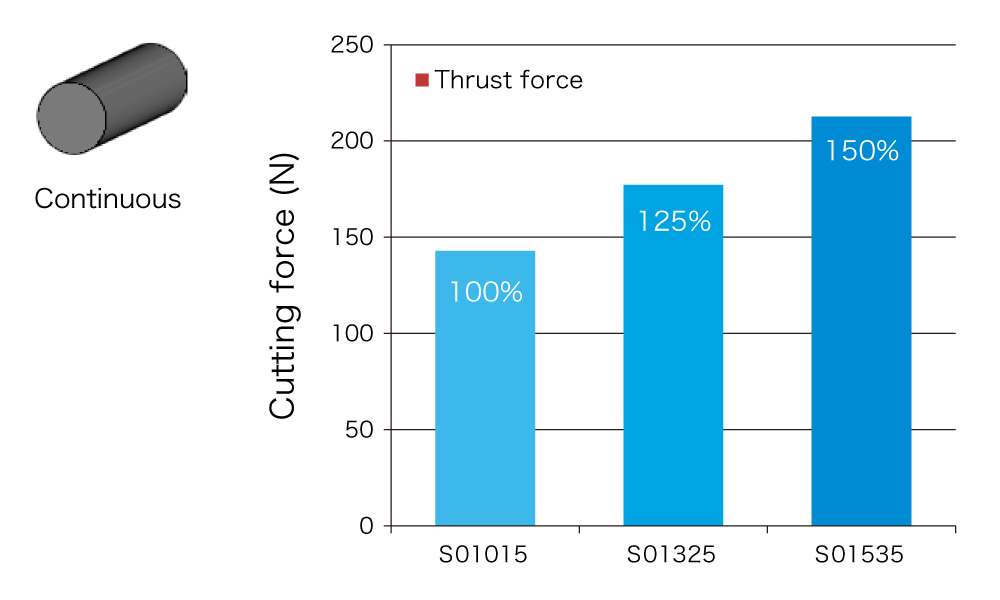

As the edge preparation increases the tool pressure on the insert increases.

[ Cutting conditions ]

SCM415(HRC63-65)

vc=200m/min f=0.1mm/rev ap=0.2mm

670 SFM f=.004 IPR p=.008 inch

DRY

[ Insert ]

TNGA160408

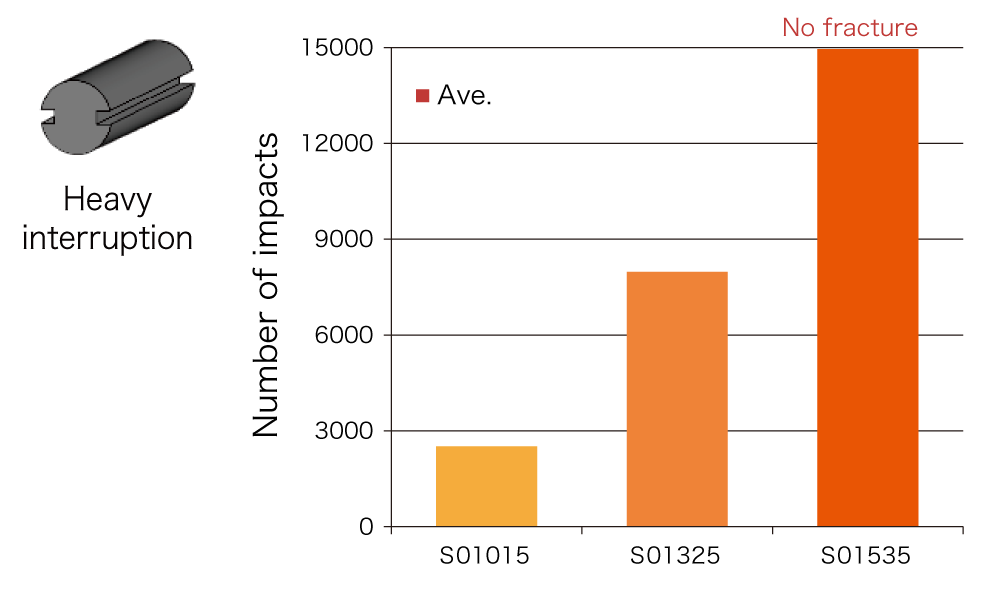

There is a direct correlation between an increase in the edge preparation and improvement of insert fracture resistance.

[ Cutting conditions ]

SCM415(HRC63-65)

vc=75m/min f=0.1mm/rev ap=0.3mm

250 SFM .004 IPR .012 DOC

DRY

[ Insert ]

TNGA160408

| ●1st Recommendation 〇2nd Recommendation |

||||||||

| Grade | Material | Operation type | Machining | Cutting speed (m/min) Cutting speed (SFM) | Feed(mm/rev) Feed(IPR) | DOC(mm) DOC(inch) | DRY | WET |

|---|---|---|---|---|---|---|---|---|

| B5K/B52 | Hardened material (HRC55 or above) | Turning Continuous machining | Finishing | 100 – 300 330 – 1000 | 0.05 – 0.2 .002 – .008 | 0.1 – 1.0 .004 – .040 | 〇 | ● |

| OD Turning of shaft parts | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| B5K |

6 pcs / corner

|

|

| Competitor’s coated CBN |

3 pcs / corner

|

|

ZC7 achieved longer tool life per corner and significantly reduced tool costs with 4 corners compared to the competitor’s 2 corner CBN.

| ID boing of automotive parts | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| B52 |

240 pcs / corner

|

|

| Competitor’s coated CBN |

200 pcs / corner

|

|

ZC7 machined the same number of parts as the competitor’s CBN.

ZC7 performance was much more stable and significantly reduced tool costs for the customer.

For more information about this product, visit our online e-catalog, or download the catalog/product report

Other recommend products