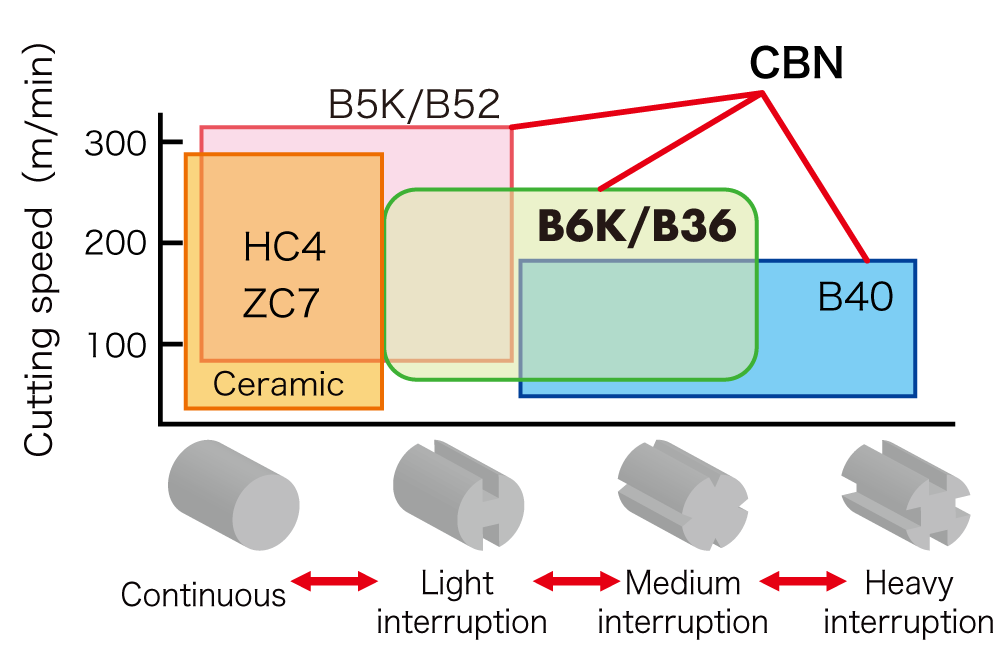

For light to medium interrupted machining | CBN for machining hardened material

Light to medium interrupted machining of hardened materials of HRC55 or above

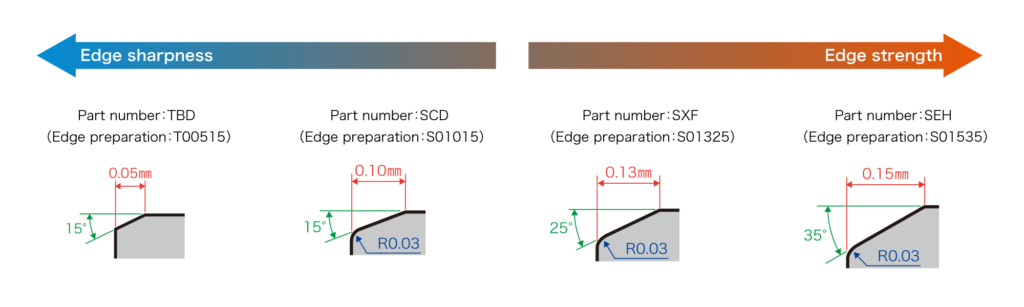

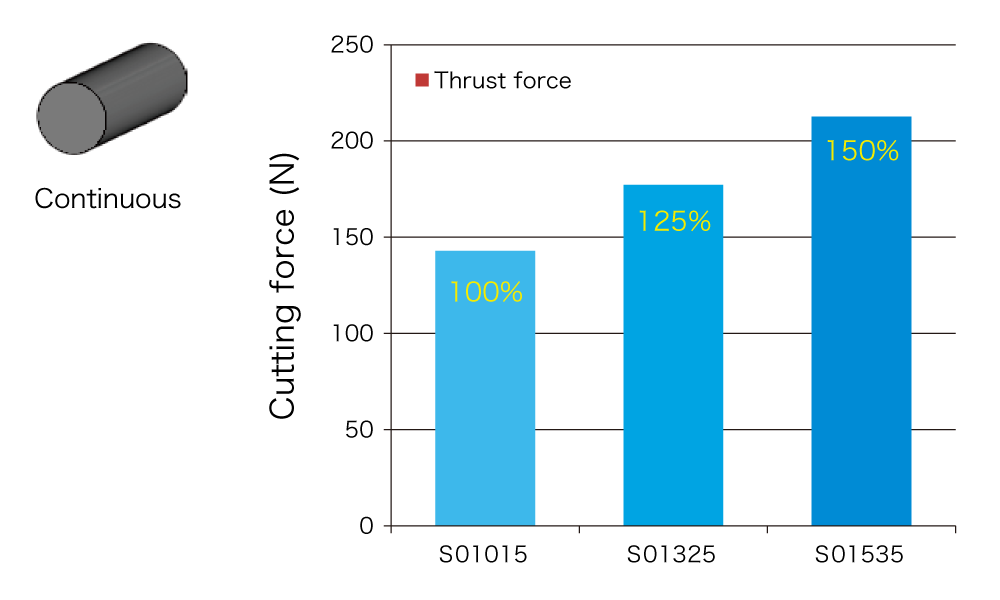

As the edge preparation increases the tool pressure on the insert increases.

[ Cutting conditions ]

SCM415(HRC63-65) m

vc=200m/min f=0.1mm/rev ap=0.2mm

670 SFM .004 IPR .008 DOC

DRY

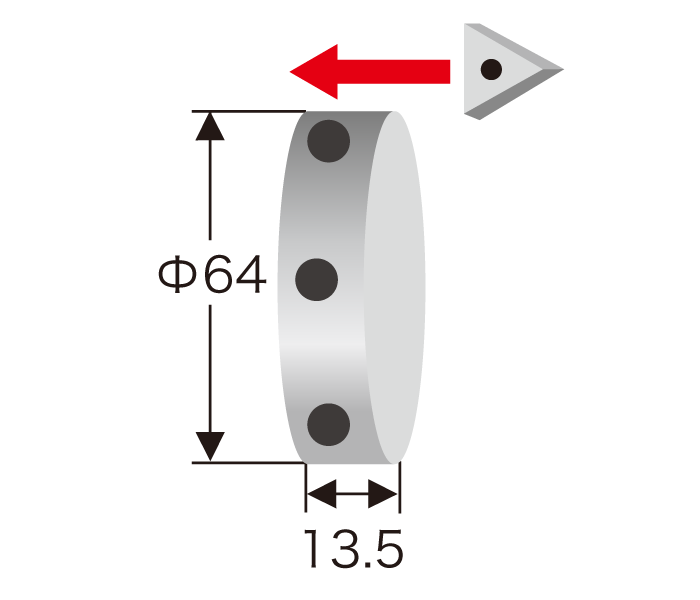

[ Insert ]

TNGA160408

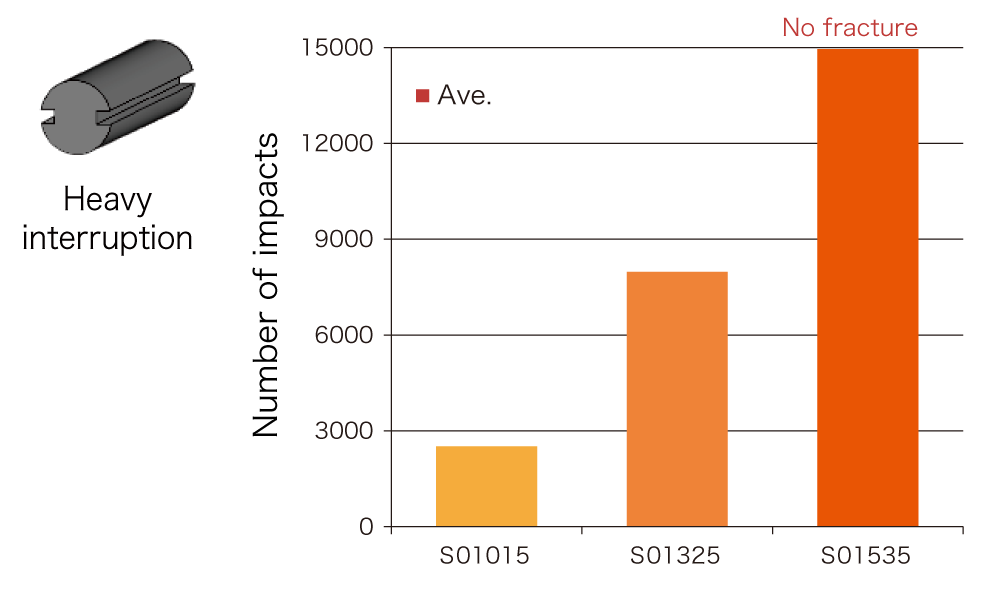

There is a direct correlation between an increase in the edge preparation and improvement of insert fracture resistance.

[ Cutting conditions ]

SCM415(HRC63-65)

vc=75m/min f=0.1mm/rev ap=0.3mm

250 SFM .004 IPR .012 DOC

DRY

[ Insert ]

TNGA160408

| Grade | Material | Operation type | Machining | Cutting speed (m/min) Cutting speed (SFM) | Feed(mm/rev) Feed(IPR) | DOC(mm) DOC(inch) | DRY | WET |

|---|---|---|---|---|---|---|---|---|

| B6K/B36 | Hardened material (HRC55 or above) | Turning Light to medium interrupted machining | Finishing | 40 – 240 130 – 800 | ~ 0.15 ~ .006 | 0.1 – 1.0 .004 – .040 | ● | ● |

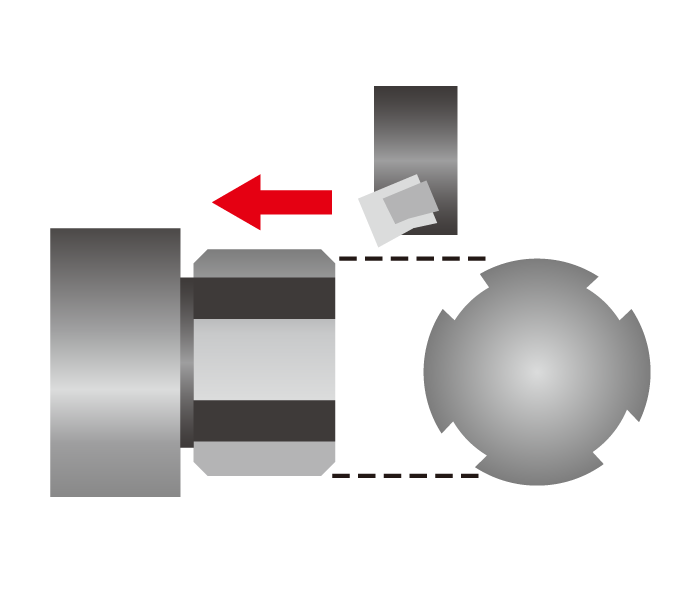

| Interrupted OD turning of machine parts | ||

|---|---|---|

|

|

|

| Front turning Heavy interruption | ||

|

||

|

||

|

||

|

||

| B6K |

700 pcs / corner

|

|

| Conventional tool |

400 pcs / corner

|

|

| Interrupted OD turning of automotive parts Steel – carburized & quenched | ||

|---|---|---|

|

|

|

| Front turning Heavy interruption | ||

|

||

|

||

|

||

|

||

| B6K |

400 pcs / corner

|

|

| Conventional tool |

150 pcs / corner

|

|

For more information about this product, visit our online e-catalog, or download the catalog/product report

Other recommend products