For continuous machining | Alumina TiC based ceramics

| Grade | Material | Operation type | Machining | Cutting speed (m/min) Cutting speed (SFM) | Feed(mm/rev) Feed (IPR /IPT) | DOC(mm) DOC(inch) | Coolant |

|---|---|---|---|---|---|---|---|

| ZC4 | Harden material | Turning | Finishing | 40 – 210 130 -690 | 0.07 – 0.2 .003 – .008 | 0.1 – 0.7 .004 – .028 | DRY / WET |

| HC4 |

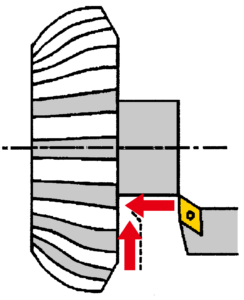

| Gear machining | ||

|---|---|---|

|  | |

| ||

| ||

| ||

| ||

| ZC4 | 60 pcs / corner | |

| Competitor’s black ceramic | 30 pcs / corner | |

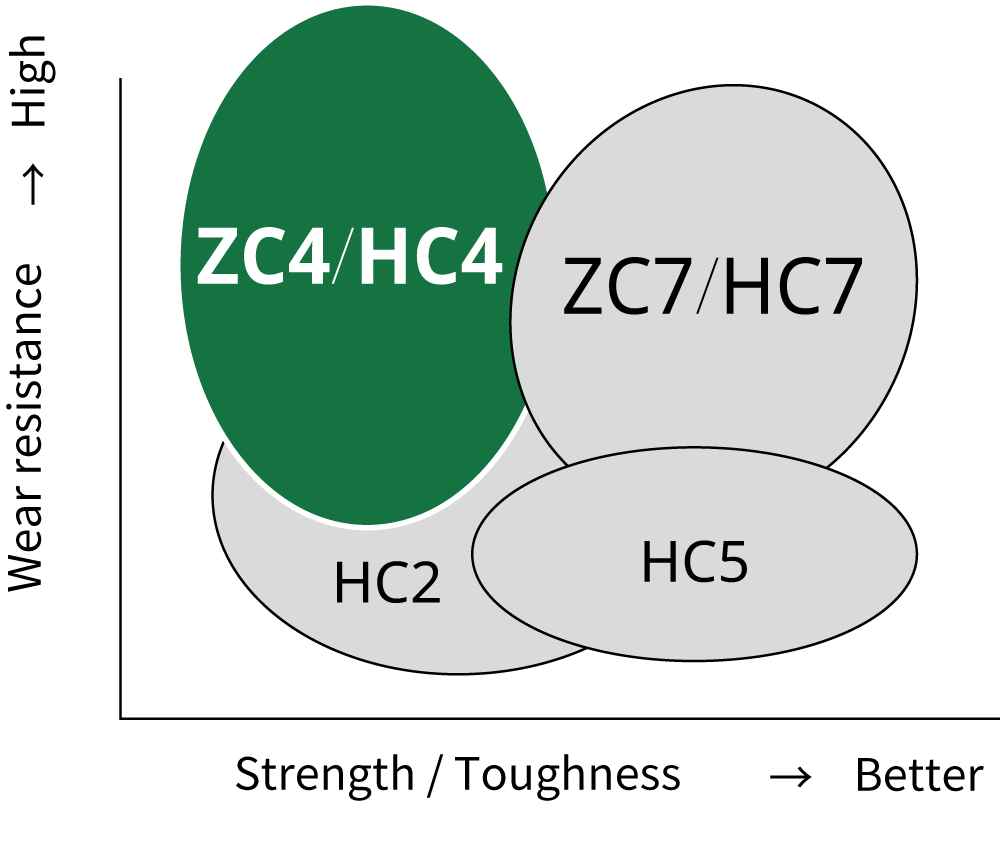

ZC4 has superior wear resistance and twice the tool life extension compared to competitors’ tool.

For more information about this product, visit our online e-catalog, or download the catalog/product report

Other recommend products