Milling cutter for machining aluminum parts | PCD inserts

Milling aluminum

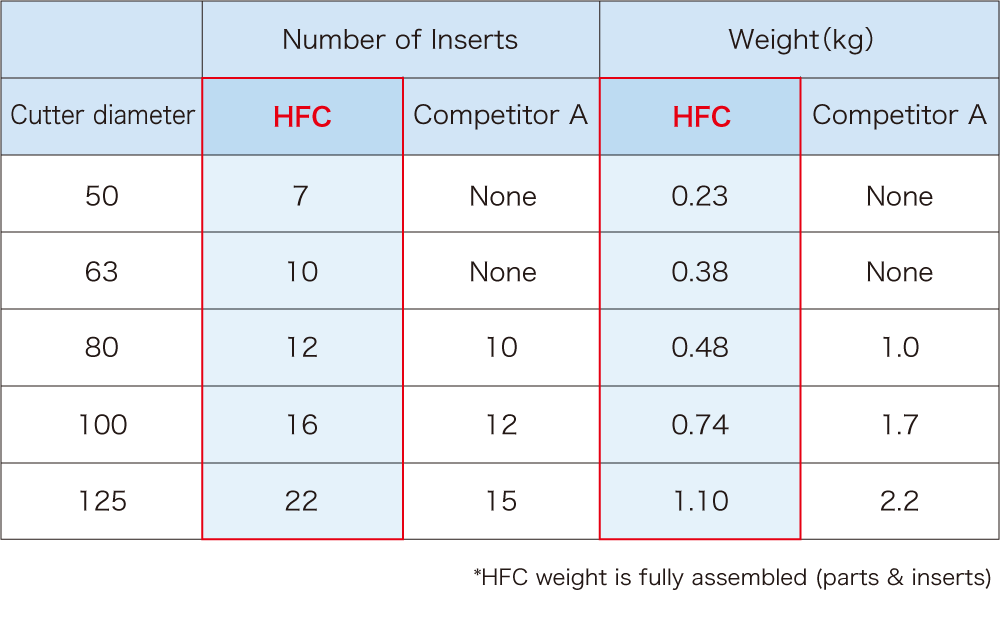

HFC cutter weight is half that of others on the market

A

125mm

4.921”

cutter + BT30 arbor* weighs

2kg

4.4 lbs

or less.

At that weight, the

125mm

4.921”

cutter can even be used on a compact machine!

* Using a BT30-FMNA25.4-40 (

0.7kg

1.54 lbs

)

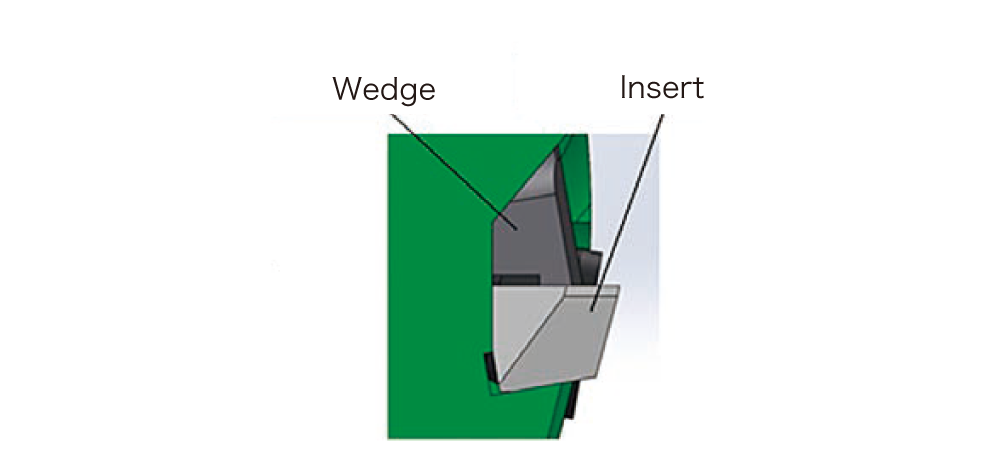

Unique pocket design uses a wedge shape and centrifugal forces to help prevent the insert from sliding out.

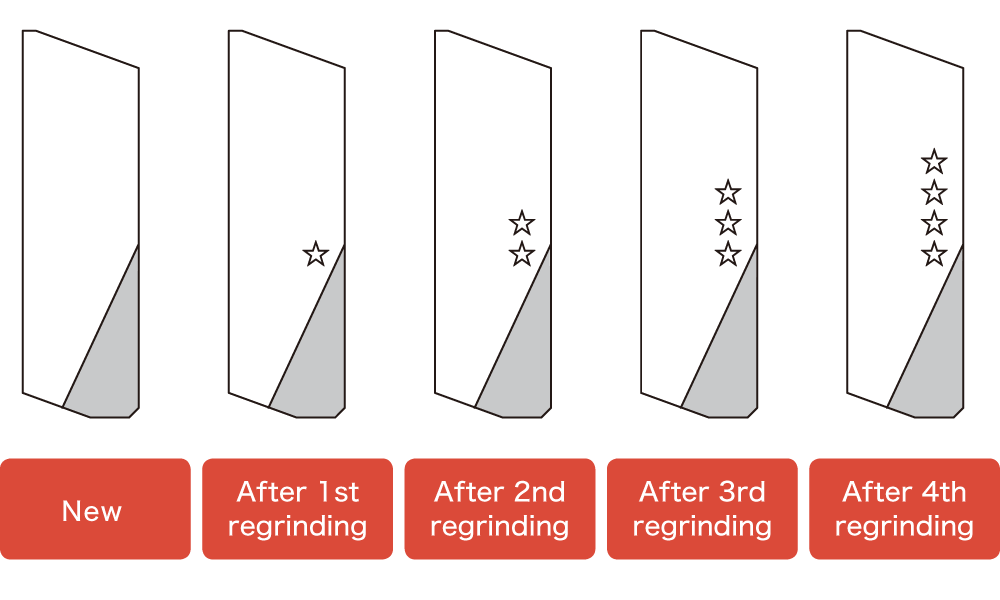

*The number of re-grinds per insert may vary depending upon cutting edge damage evaluation.

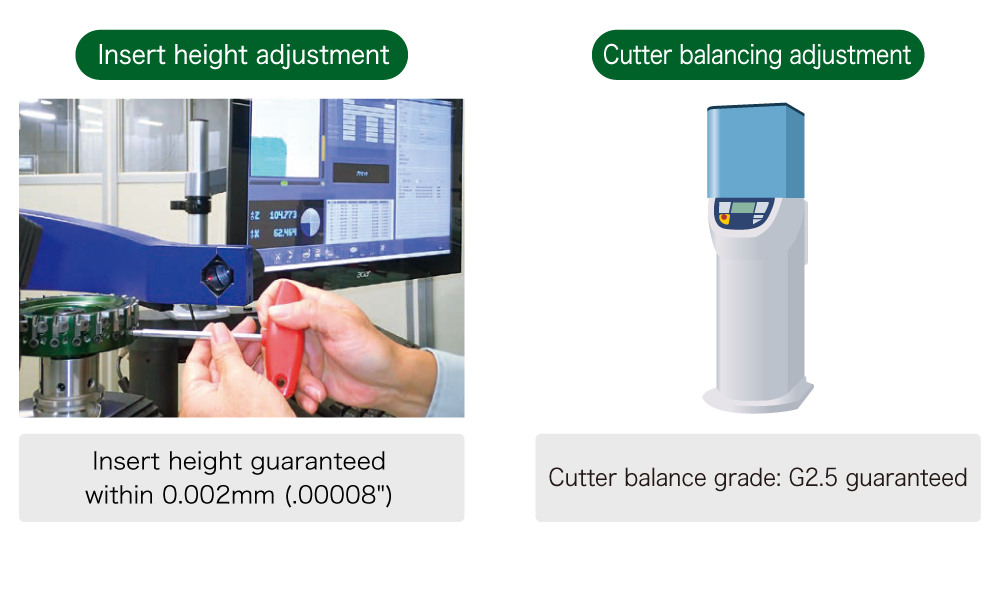

Process

1. Loosen the axial adjustment screw

2. Install inserts (lightly hand tighten)

3. Clean the inserts

4. Adjust height of inserts (initial setup)

5. Tighten wedge set screw (firmly tighten)

6. Final insert height adjustment

| ●1st Recommendation 〇2nd Recommendation |

||||||

| Grade | Material | Cutting speed (m/min) Cutting speed (SFM) | Feed(mm/rev) Feed(IPR) | DOC(mm) DOC(inch) | DRY | WET |

|---|---|---|---|---|---|---|

| PD1 | Aluminum alloy (SI≦13) | 900 – 3000 – 5000 3000 – 10000 – 17000 | 0.05 – 0.12 – 0.20 .0020 – .0047 – .0079 | ~ 6.35 ~ .25 | 〇 | ● |

| PD1 | Aluminum alloy (Si≧13) | 300 – 600 – 900 1000 – 2000 – 3000 | 0.05 – 0.12 – 0.20 .0020 – .0047 – .0079 | ~ 6.35 ~ .25 | 〇 | ● |

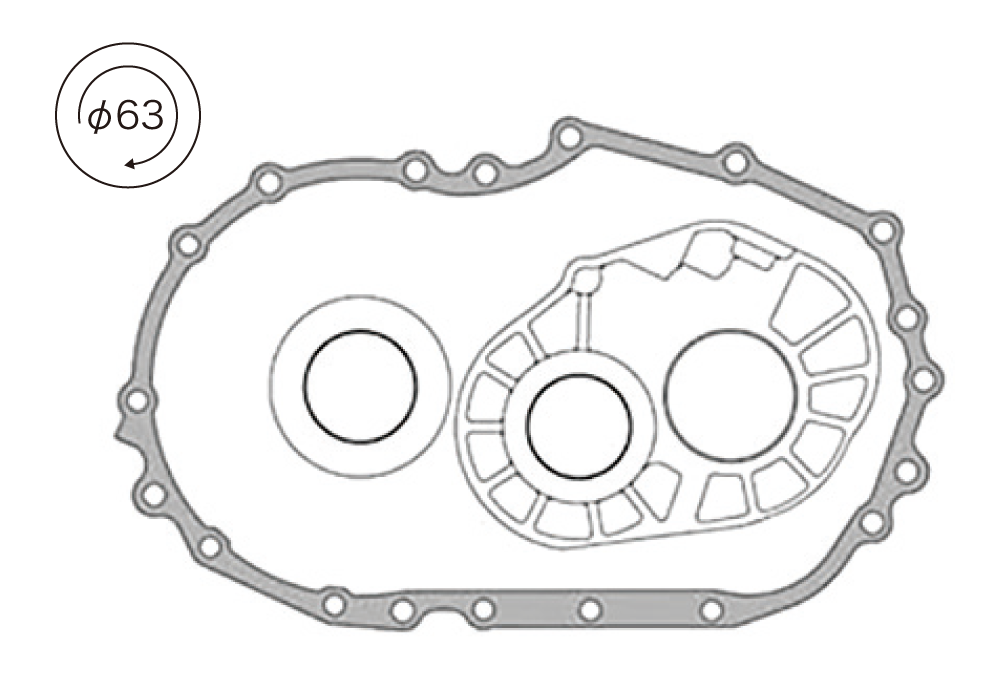

| Transmission case ( ⌀63 ⌀2.48” , 10 edges, WET) | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| HFC |

10,000 mm/min

400 IPM

|

| Competitor’s PCD cutter |

7,920 mm/min

310 IPM

|

HFC cutter achieved 1.3 times higher productivity than the competitor’s PCD cutter.

For more information about this product, visit our online e-catalog, or download the catalog/product report