Excellent notch and flank wear resistance when roughing gray cast iron|Sialon ceramic

Excellent notch and flank wear resistance when roughing gray cast iron|Sialon ceramic

Ceramic grade with the best fracture resistance

Stable machining even in tough applications

Significantly improve productivity when replacing carbide tools with SX9

Features

- The toughest ceramic grade

- Excellent thermal shock and fracture resistance due to the needle-shaped particles formed during the ceramic manufacturing process

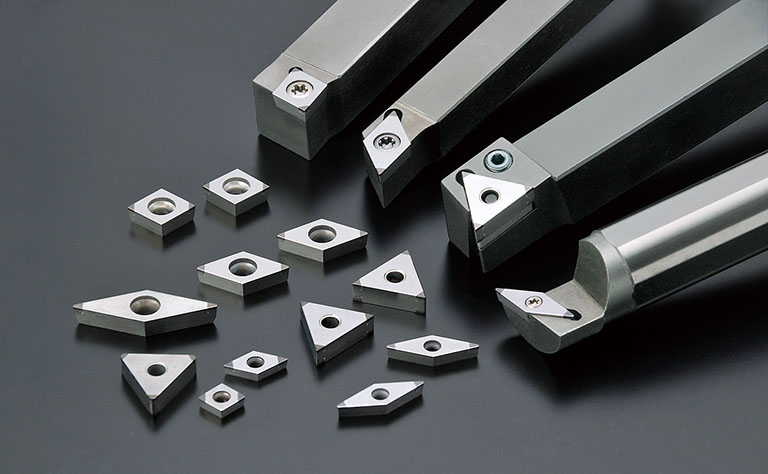

Tooling application

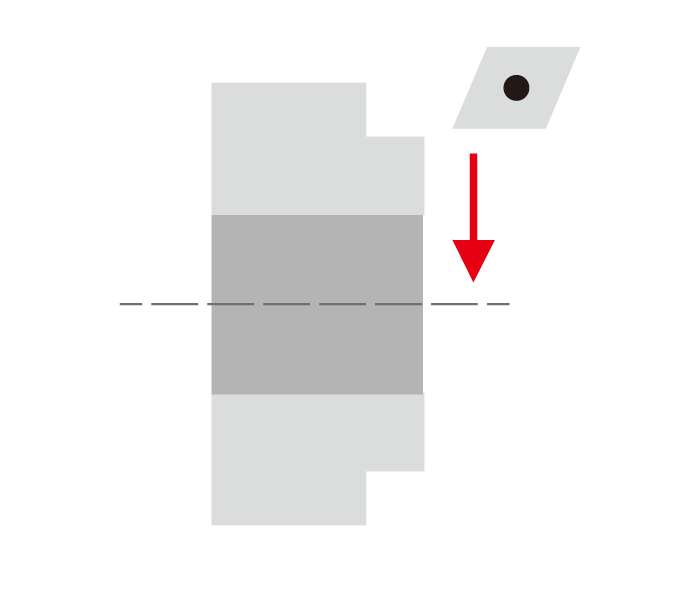

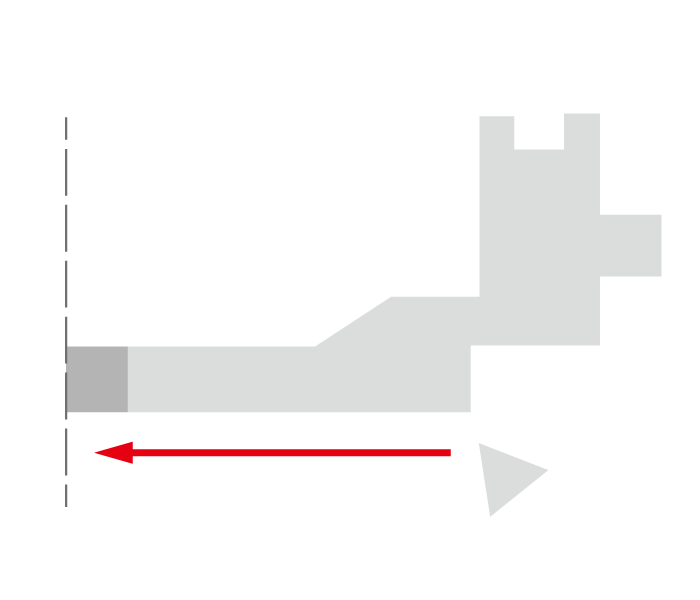

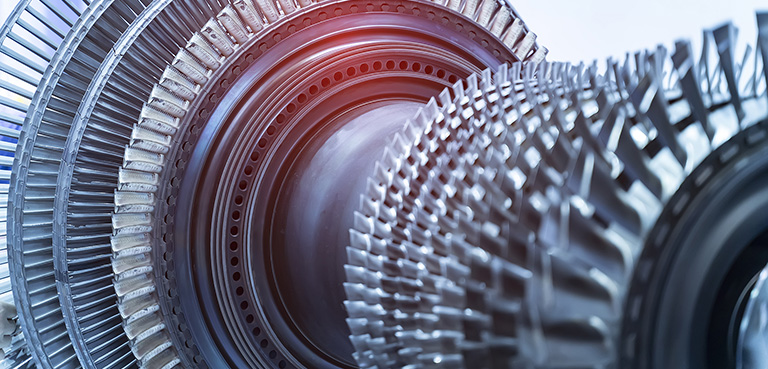

Gray cast iron with scale

Rough Turning / Milling /End milling

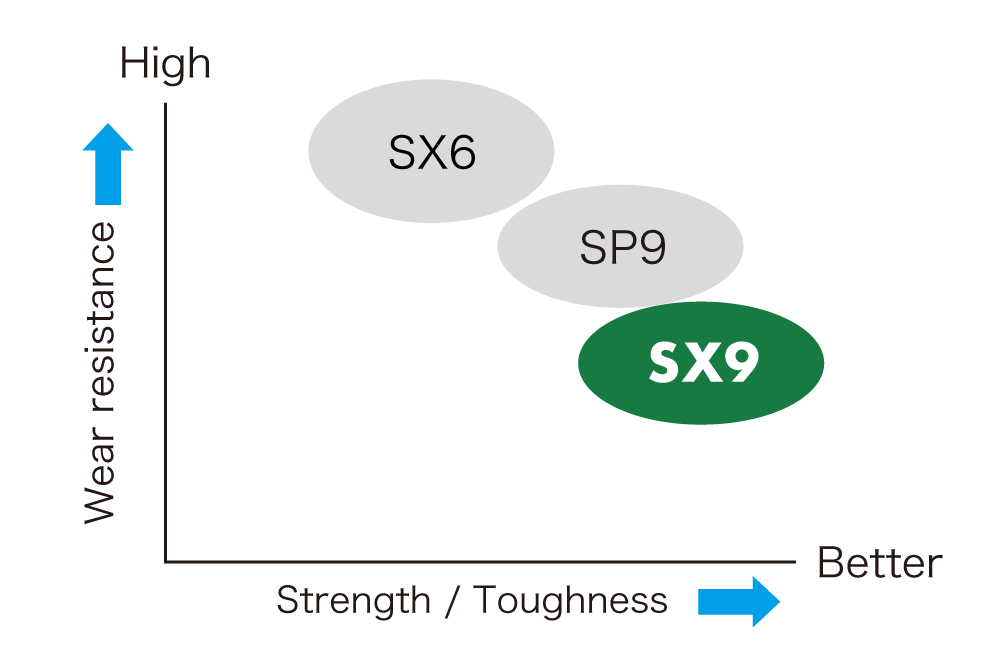

Grade characteristics

Cutting conditions

Scroll the table →

| Grade | Material | Operation type | Machining | Cutting speed (m/min) | Feed(mm/rev) | DOC(mm) | Coolant |

|---|---|---|---|---|---|---|---|

| SX9 | Gray cast iron | Turning | Roughing with scale, Rough to semi-finish machining | 300 - 800 | 0.3 - 0.6 | -3.5 | DRY |

| Milling | 350 - 700 | 0.05 - 0.1 | - |

Gray cast iron rough milling application

Gray cast iron ceramic End mill application

Case study

| Machine parts | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| SX9 | 850 pcs / corner |

|

| Competitor’s CVD coated carbide | 300 pcs / corner |

|

- SX9 achieved stable machining results in this interrupted turning operation.

By replacing the CVD coated carbide with ceramic there was a significant reduction in cutting tool costs and an increase in production.

| Brake disc | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| SX9 | 360 pcs / corner |

|

| Whisker ceramic | 264 pcs / corner |

|

- SX9 machined at the same cutting conditions as the current whisker ceramic and resulted in a reduction in tooling cost for the customer.

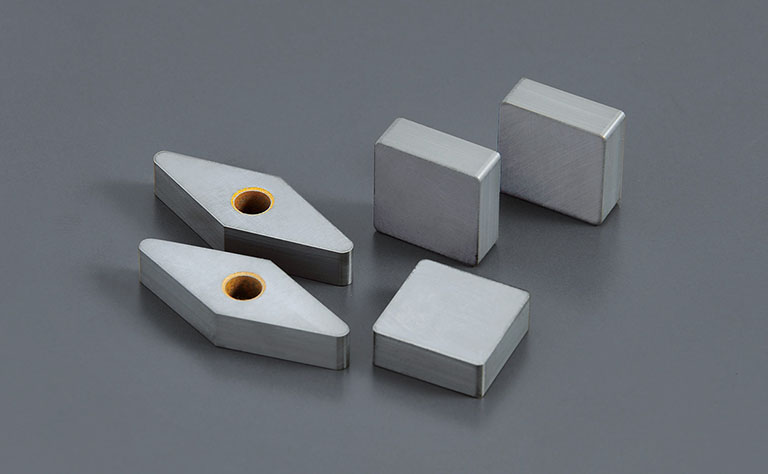

Tool lineup

Other recommended products

-

SX6Exceptional wear resistance for rough machining of gray cast iron| Silicon nitride ceramic

First recommendation for roughing gray cast iron

-

HC1/HW2Continuous machining of gray cast iron| Alumina ceramic (White ceramics)

First recommendation for finishing gray cast iron

-

B23/B30High-speed finishing of gray cast iron| Uncoated CBNs

Best CBN grades for machining gray cast iron

-

CP1Roughing gray cast & ductile cast iron / CVD coated carbide

CVD coated carbide grade ideal for roughing

Useful information

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕 Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕 Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics

Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics How to Make Ceramic Cutting Tools from Scratch

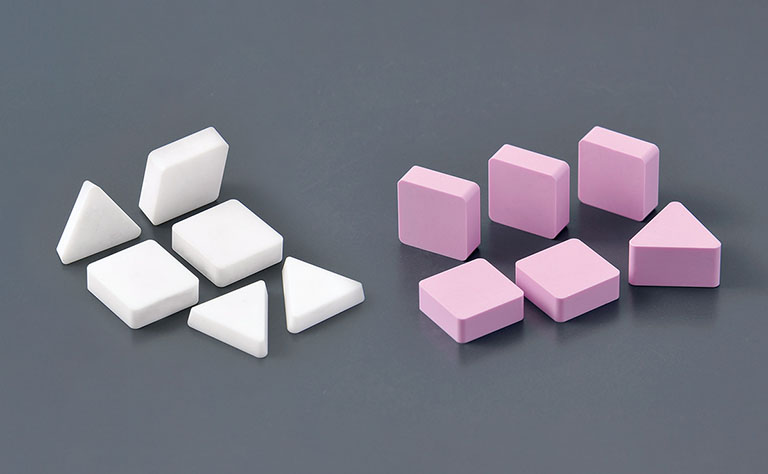

How to Make Ceramic Cutting Tools from Scratch