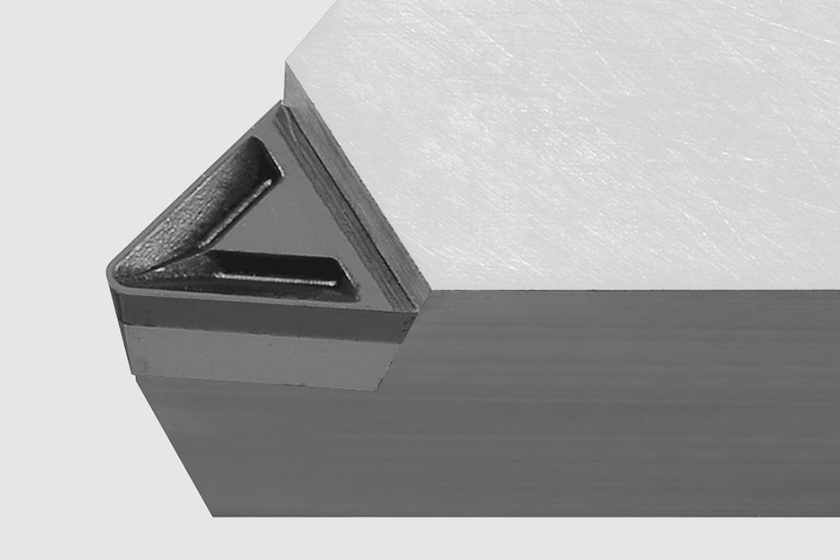

有色金属加工,如铝、黄铜、树脂、铜、碳、陶瓷等

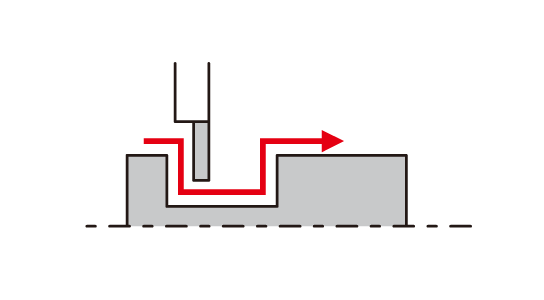

前扫/后扫/切槽

| 线轴 | |

|---|---|

|

|

|

|

|

|

|

|

|

|

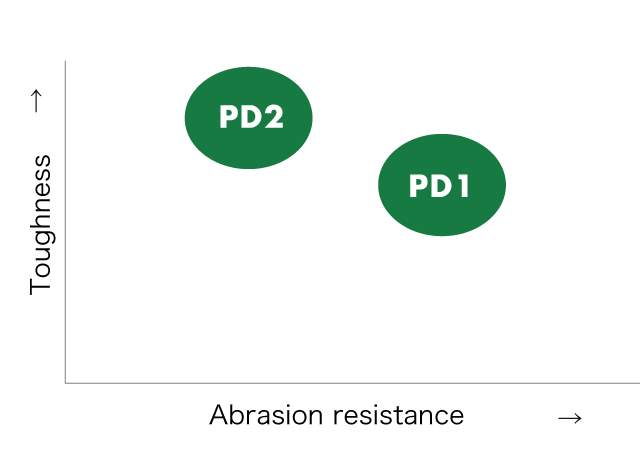

| PD1 |

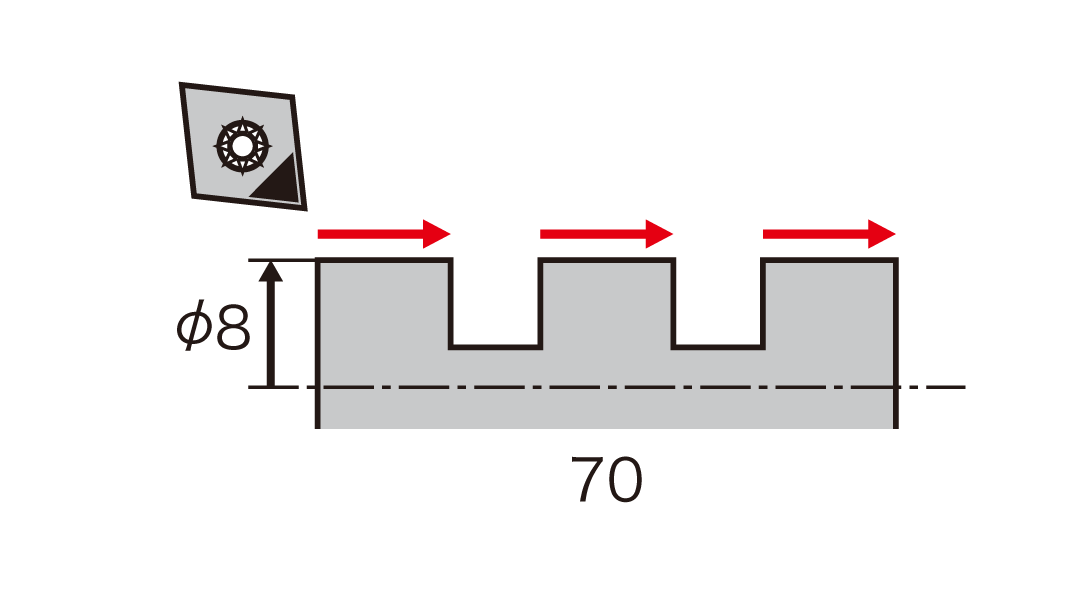

10,000 件/角

|

| 竞争对手的焊接型硬质合金刀片 | 1,000 件/角 |

PD1 缩短了加工时间,并且性能良好,没有出现溶着问题,从而实现了良好的表面光洁度。

| 线轴 | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| PD2 |

10,000 件/角

|

| 竞争对手的 PCD |

5,000 件/角

|

与竞争对手的 PCD 相比,PD2 具有出色的耐磨损性,生产率提高了一倍。

有关该产品的更多信息,请访问我们的在线电子目录,或下载目录/产品报告