Roughing to finishing of ductile cast iron & gray cast iron| Coated Silicon Nitride Ceramic

Roughing to finishing of ductile cast iron & gray cast iron| Coated Silicon Nitride Ceramic

Covers roughing to finishing operations

An extremely tough material and CVD coating combine to achieve excellent fracture and wear resistance

Achieve long tool life even at a low cutting speed (Vc = 300m/min) due to the CVD coating

Product video

Features

- The combination of an extremely tough grade with a CVD coating achieves excellent fracture resistance and wear resistance

- Lighter edge preparations reduce tool pressure

- Excellent for finishing operations

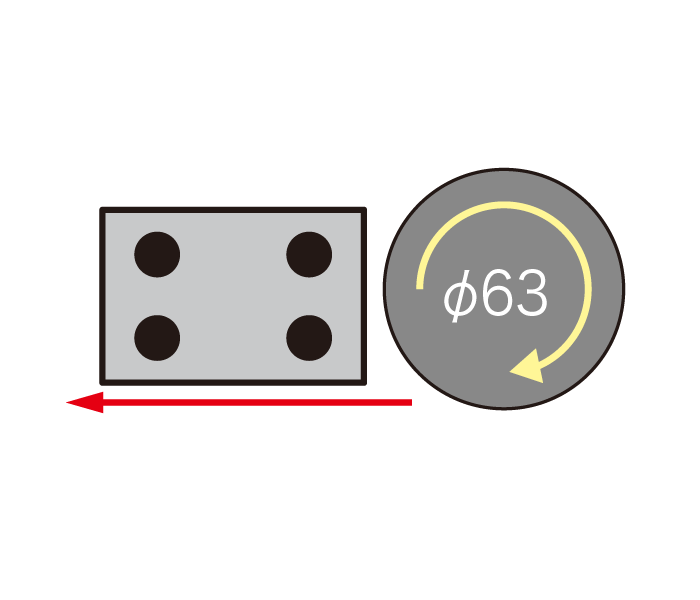

Tooling application

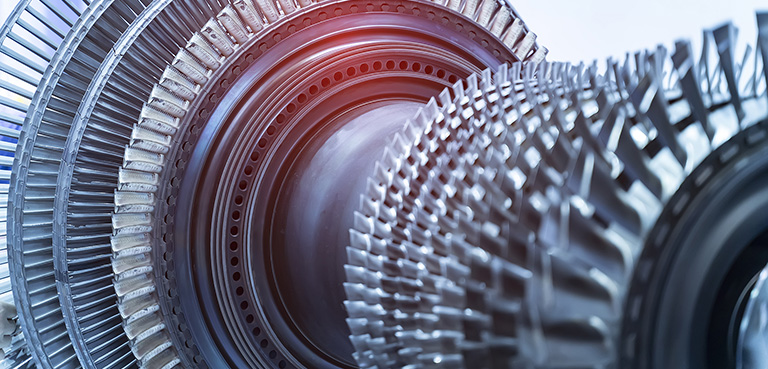

Ductile / Gray cast iron

Turning/Milling

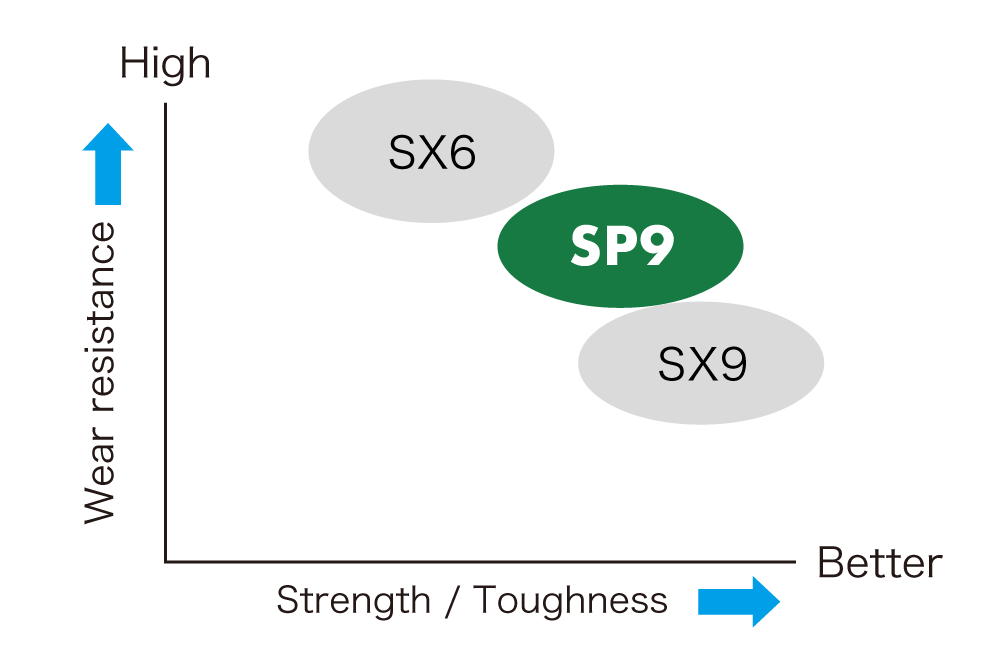

Grade characteristics

Cutting conditions

Scroll the table →

| Grade | Material | Operation type | Machining | Cutting speed (m/min) | Feed(mm/rev) | DOC(mm) | Coolant |

|---|---|---|---|---|---|---|---|

| SP9 | Gray cast iron | Turning | Turning Roughing ~ Finishing | 350 - 800 | 0.3 - 0.6 | -3.5 | DRY |

| Ductile cast iron | 250 - 550 | 0.15 - 0.4 | -3.0 | DRY | |||

| Gray cast iron | Milling | Milling Roughing ~ Semi-Finishing | 350 - 700 | 0.07 - 0.25 | -6.0 | DRY | |

| Ductile cast iron | 400 - 800 |

Gray cast iron rough turning application

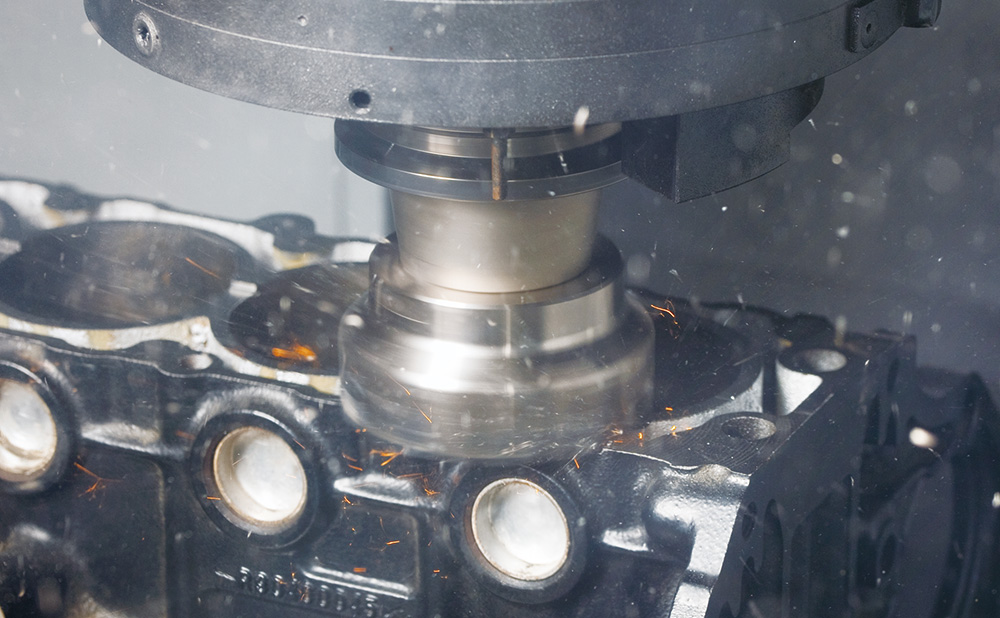

Gray cast iron milling application

Case study

| Differential case | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| SP9 | C/T 30 seconds / part |

|

| Competitor’s CVD coated carbide | C/T 60 seconds / part |

|

- SP9 machined at a higher speed than the competitor's CVD coated carbide and reduced cutting time by 50%.

| Auto parts | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

|

||

| SP9 | 1,300 pcs/ corner |

|

| Competitor's silicon nitride ceramic | 800 pcs/ corner |

|

- SP9 achieved 1.6 X higher tool life than the competitor's ceramic.

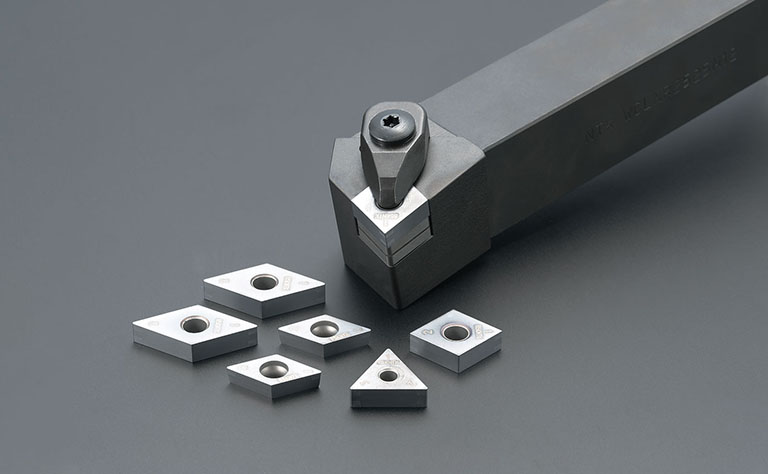

Tool lineup

Other recommended products

-

HC6For machining ductile cast iron| TiC ceramic + alumina

Specialized ceramic for finishing ductile iron

-

B5K/B52CBN grades for finishing ductile cast iron| Coated (B5K) / Un-coated (B52)

Best CBN grades for high-speed finishing of ductile cast iron

-

CP1Roughing gray cast & ductile cast iron / CVD coated carbide

CVD coated carbide grade ideal for roughing

-

SX6Exceptional wear resistance for rough machining of gray cast iron| Silicon nitride ceramic

First recommendation for roughing gray cast iron

Useful information

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕 Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕 Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics

Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics How to Make Ceramic Cutting Tools from Scratch

How to Make Ceramic Cutting Tools from Scratch