Hexagon : AF1.0 ‒ AF1.4Socket machining tool | Swiss Tooling

Hexagon : AF1.0 ‒ AF1.4Socket machining tool | Swiss Tooling

For MEDICAL Components

Users Wanted!

Be the first to try the latest development from NTK.

Introduction Movie

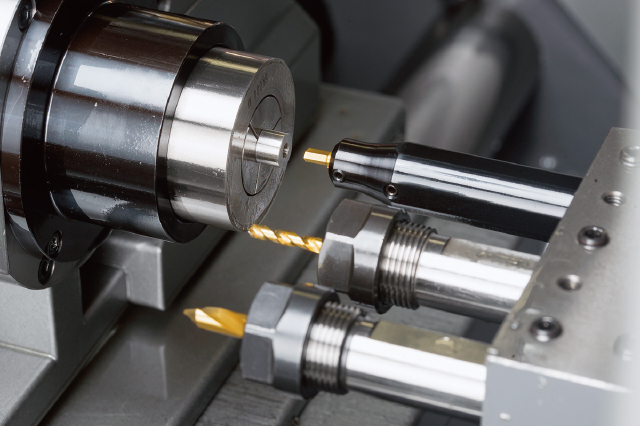

Applications

- Dental Implants

- Bone Screws

- Medical device components

Work Materials

Titanium / Stainless steel / PEEK / TEFLON

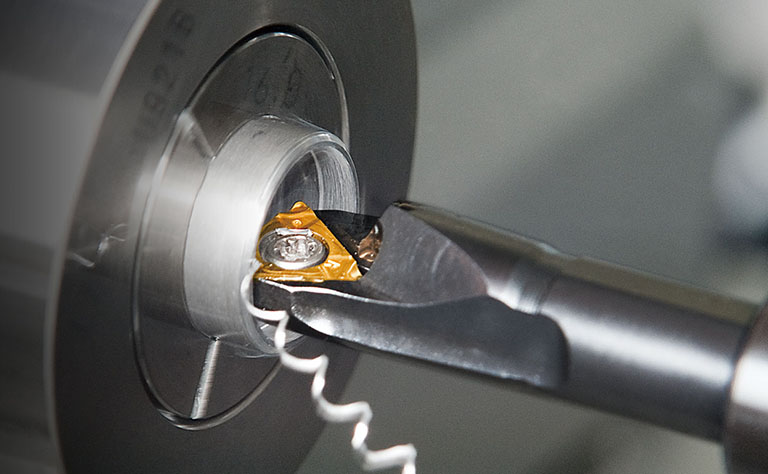

Comparison Chart of HEX Socket Machining

scroll →

| Tool Pressure | Cycle Time |

Flexibility |

Tool Cost |

||

|---|---|---|---|---|---|

|

◎ | △ *Can be off-set by over-wrapping operation |

○ | ◎ | Less tool pressure -especially on small diameter parts One size can cover several socket sizes |

| Broach Tool | △ | ○ | ╳ | △ | Need to have tools for each socket size |

- Rotary-broach is an efficient way for Hexagon socket. But tool pressure is high and often times it pushes part too hard.

- SHAPER DUO can make Hexalobular(6-lobe) socket faster and simpler.

| Processing condition | |

|---|---|

|

|

|

|

|

|

|

|

scroll →

| Pilot hole | Starting"X"position | Final"X"position | Roughing pass | Finishing pass |

|---|---|---|---|---|

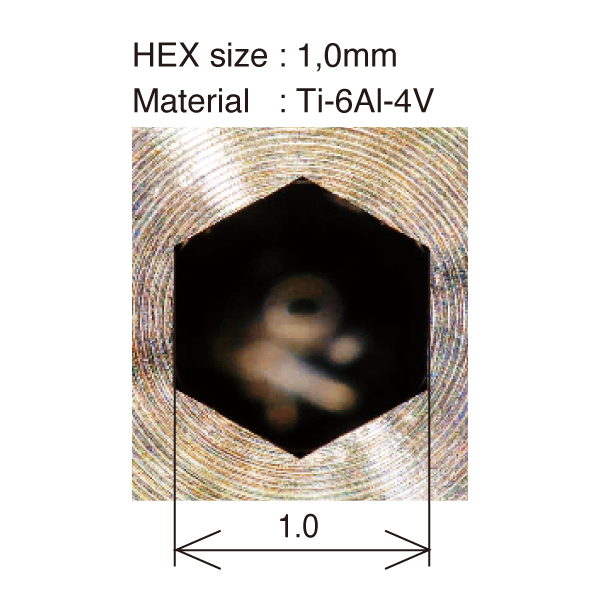

| 0.9mm | 0.895mm | 1.155mm | 6pass | 1pass |

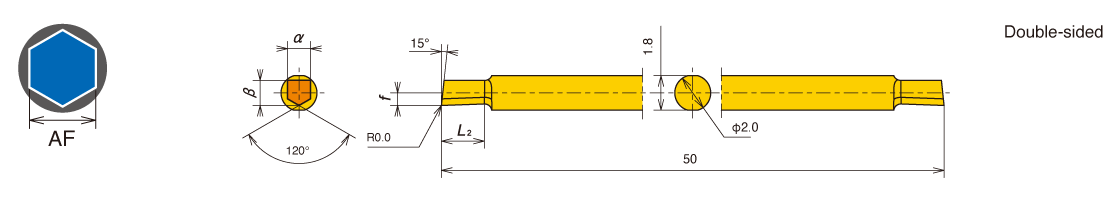

Insert Bar -Hexagon

scroll →

We are in search of users to try the latest item development by NTK. No official release date yet.

scroll →

| (mm) | |||||||

| Sample items | HEX size range | Base AF | L2 | α | β | f | Pilot hole |

|---|---|---|---|---|---|---|---|

| TM4 TEST14-0179FN-1 | 1.0 ~ 1.1 | 1.0 | 1.5 | 0.65 | 0.70 | 0.35 | 0.90 |

| TM4 TEST14-0180FN-1 | 1.1 ~ 1.2 | 1.1 | 1.8 | 0.70 | 0.80 | 0.40 | 1.00 |

| TM4 TEST14-0181FN-1 | 1.2 ~ 1.3 | 1.2 | 1.8 | 0.75 | 0.90 | 0.45 | 1.10 |

| TM4 TEST14-0182FN-1 | 1.3 ~ 1.4 | 1.3 | 2.0 | 0.80 | 1.00 | 0.50 | 1.20 |

Tool lineup

Please check product catalog for tooling lineup

Other recommended products

-

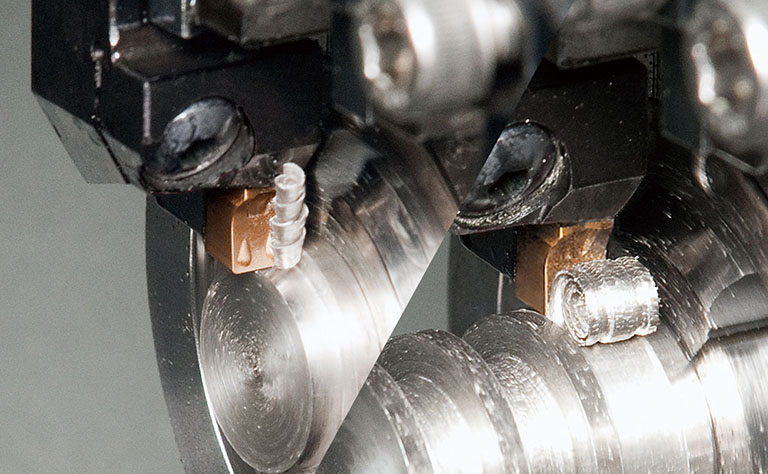

SHAPER DUOFor socket hole machining| Swiss CNC lathes

Highly productive socket hole machining

-

Mogul barsFor ID boring operations| Swiss CNC lathes

Solves common issues associated with ID boring operations

-

SCRUM DUOFor grooving| Swiss CNC lathes / Conventional CNC lathes

Highly rigid holder design

-

DT4/DM4Difficult-to-cut materials | Carbide grade for Swiss CNC lathes

Superior heat resistance

Useful information

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining

The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining

Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining "Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab

"Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab