chipbreakerBack turning | Swiss CNC Lathes

chipbreakerBack turning | Swiss CNC Lathes

Unique chipbreaker provides excellent chip evacuation

Achieves outstanding surface finish in single pass machining

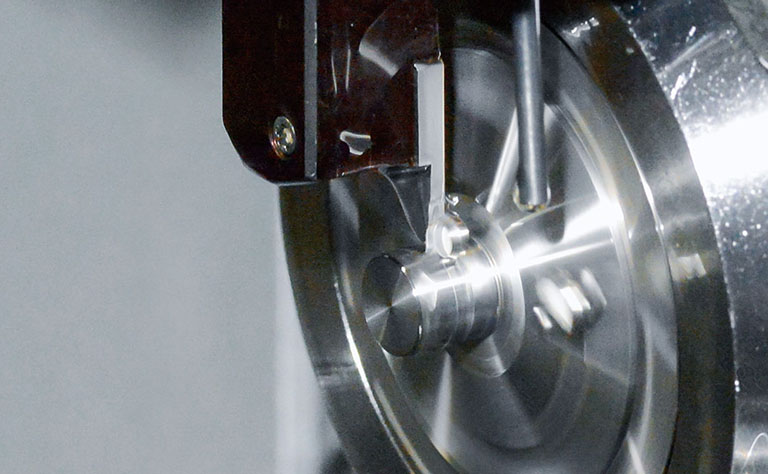

A traditional 2 pass operation can be completed in a single pass while providing chip control.

Dramatically shortens cycle time.

Product video

Features

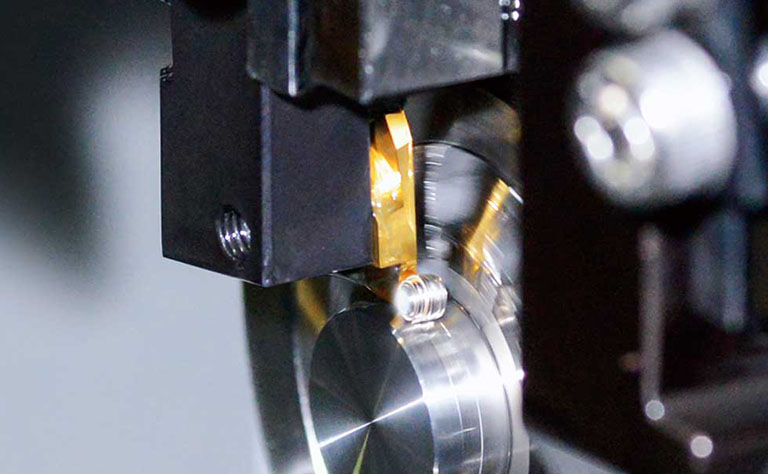

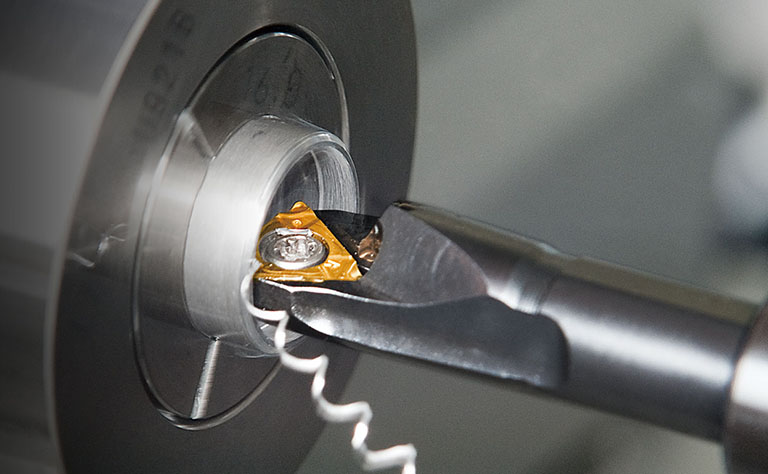

- Single pass back turning

- Up-right insert and screw clamp provides highly rigid system

- Wiper flat on cutting edge generates superior surface finishes even at high feed rates

Tooling application

Swiss CNC lathe back turning

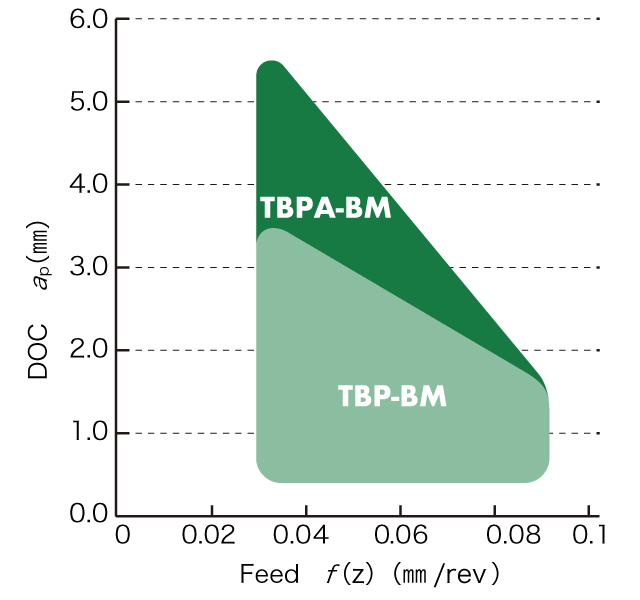

TBP/TBPA-BM chip control range

Cutting conditions

Scroll the table →

| Coated grade | Material | Operation type | Cutting speed (m/min) | Feed (mm/rev) | DOC (mm) |

|---|---|---|---|---|---|

| ST4 | Stainless | Back turning | 50 - 120 | X direction: 0.01-0.03 Z direction: 0.03 - 0.04 |

TBP-BM : 0.5-3.5 TBPA-BM : 0.5-5.5 |

| DM4 | Difficult-to-cut material / titanium alloy Alloy steel / carbon steel / hardened material |

30 -120 | X direction: 0.01-0.03 Z direction: 0.03 - 0.08 |

||

| TM4 | Non-ferrous / aluminum / plastic / general purpose | 50 - 180 | X direction: 0.01-0.03 Z direction: 0.03 - 0.08 |

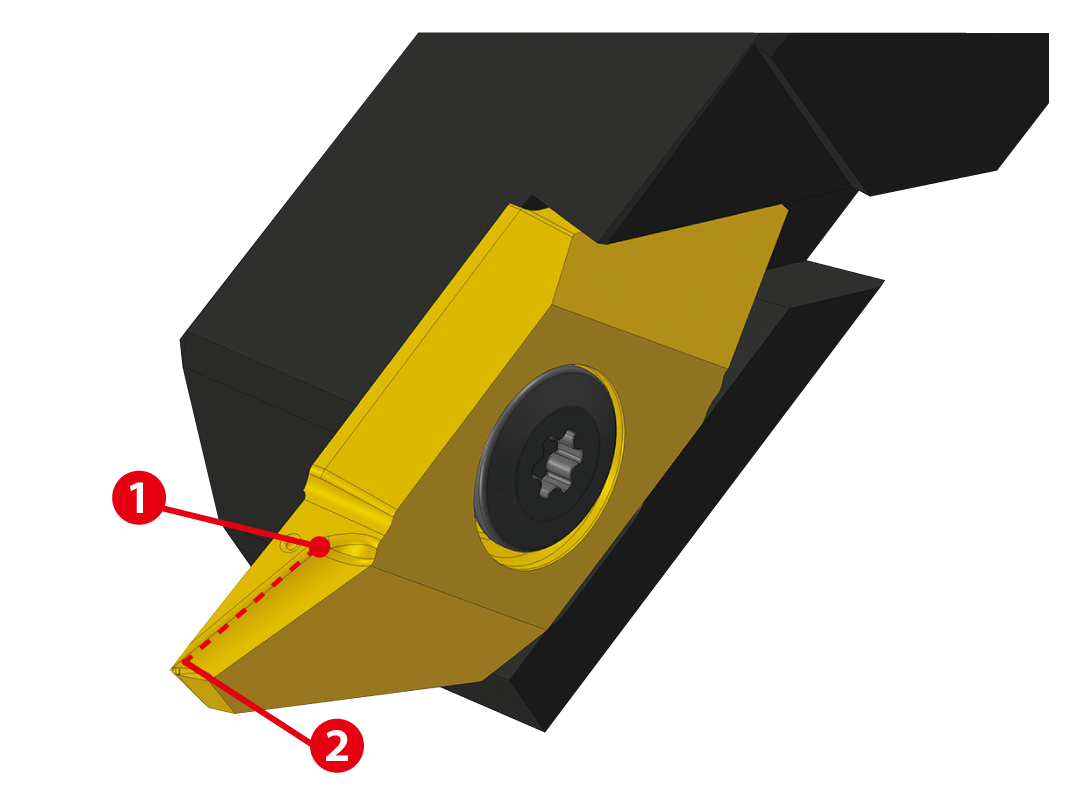

BM chipbreaker

- ① Prevents the chip from damaging the shoulder feature on the part

② Wiper flat feature generates excellent surface finish

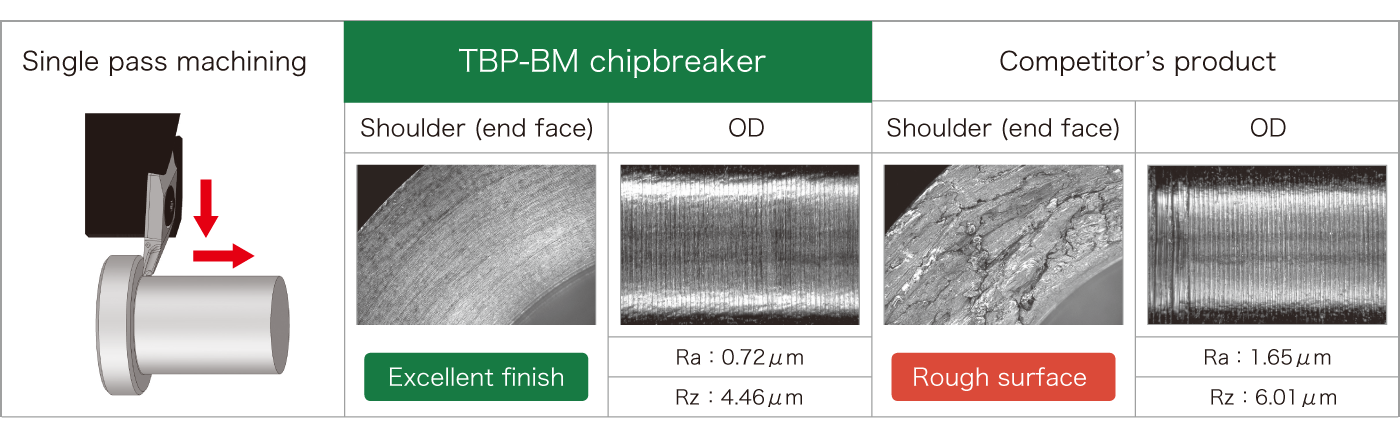

Cutting performance

- [ Cutting conditions ]

- Material : SUS304 φ16 vc=80m/min f (x)=0.02mm/rev f (z)=0.08mm/rev ap=3.0mm WET

- [ Tools used ]

- Holder : TBPR12 Insert : TM4 TBP72FR10M-BM

Case study

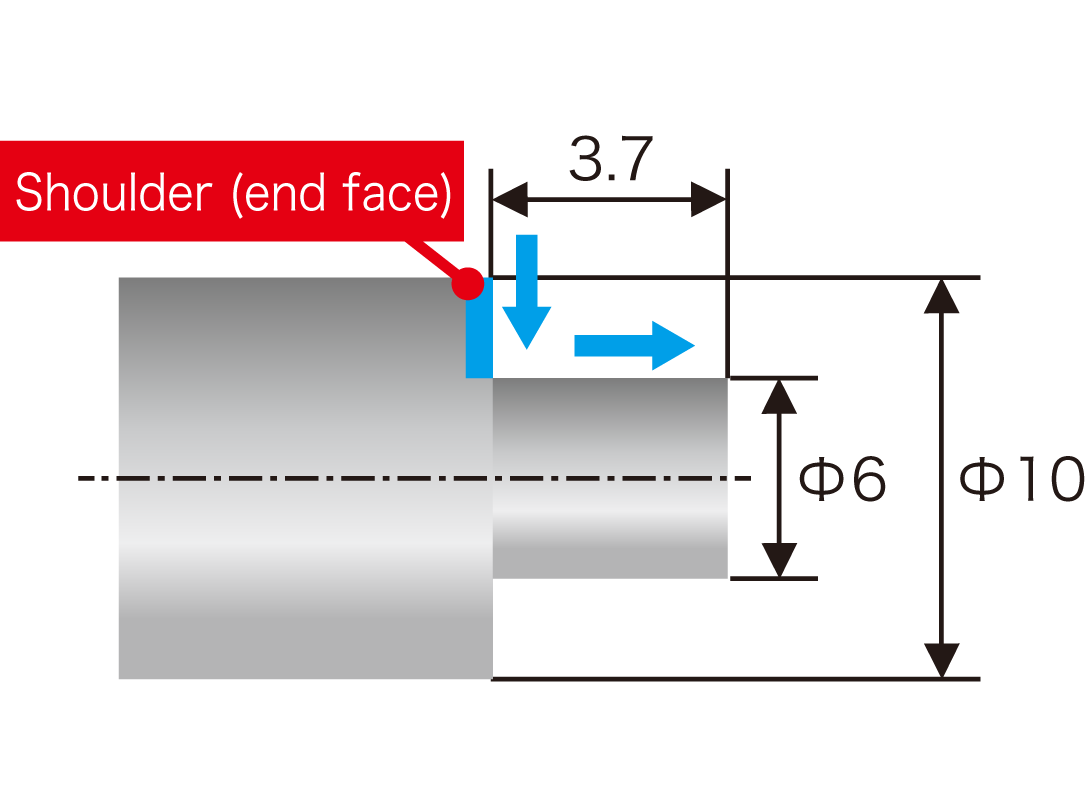

| Stud | |

|---|---|

|

|

|

|

|

|

|

|

| TBP-BM | ①1 pass machining * no extra operations required |

| Competitor’s product | ①Roughing - grooving operations |

The current process required 2 steps to complete the part feature.

NTK's BM chipbreaker achieved shortened cycle time with a single pass operation .

High quality finish on the OD and shoulder due to the chipbreaker design which evacuates chips away from the part

Tool lineup

Please check product catalog for tooling lineup

Other recommended products

-

GX chipbreakerFor grooving | Swiss CNC Lathes

Solves the issue of chips wrapping around workpiece or remaining in the groove

-

Mogul barsFor ID boring operations| Swiss CNC lathes

Solves common issues associated with ID boring operations

-

CTP/CTPA-TH chipbreaker For cut-off operations for diameters up to 16mm| Swiss CNC lathes

Special design for stainless steel cut-off applications

-

S-MILLFor end milling| Swiss CNC lathes

NTK's unique design for sharpness

Useful information

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining

The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining

Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining "Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab

"Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab