Roughing to semi-finishing of heat resistant alloys | BIDEMICS

Roughing to semi-finishing of heat resistant alloys | BIDEMICS

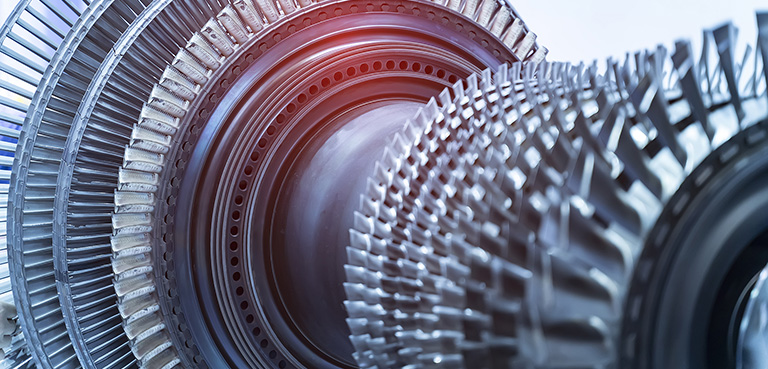

Revolutionary material for machining heat resistant alloys

Capable of ultra-high speeds of 480m/min

Higher quality and longer tool life than whisker ceramics

Applications include new aerospace part materials

Product video

Features

- Significantly better tool life at whisker's speed range

Two times faster cutting speeds than whisker

- Machining applications include powdered metal heat resistant alloy materials

Tooling application

Finishing Heat resistant alloys

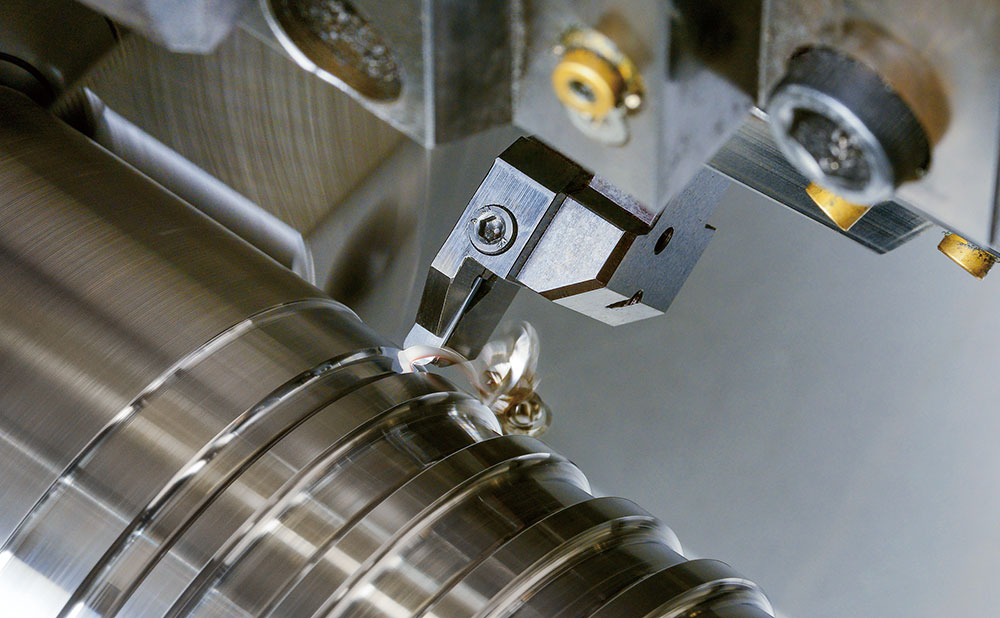

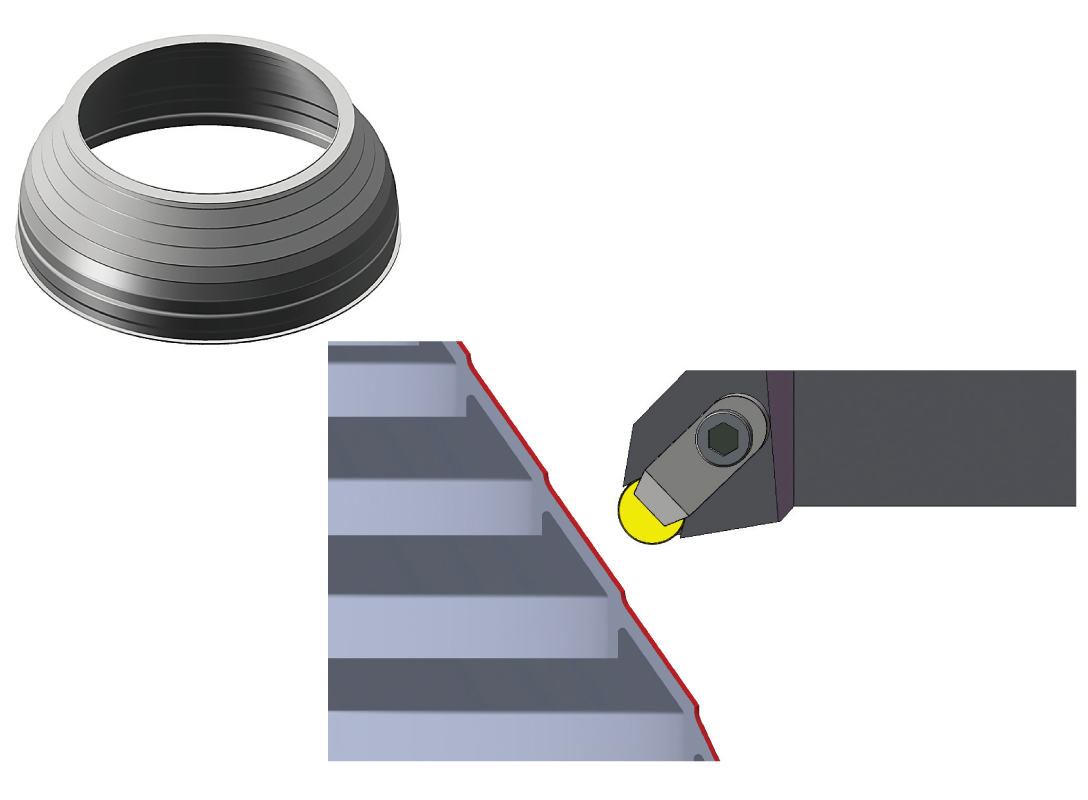

Turning / Grooving / Profiling / Roughing to Semi-finishing

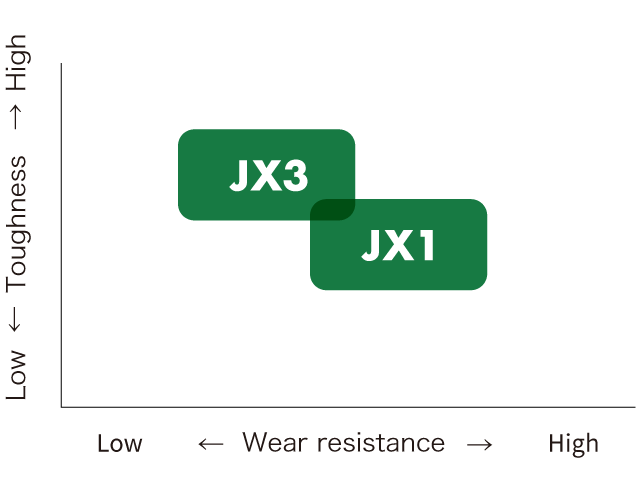

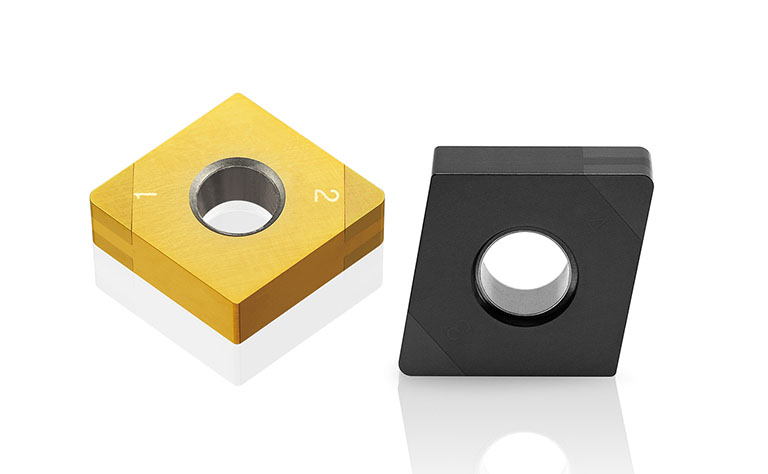

Grade characteristics

Cutting conditions

Scroll the table →

| Grade | Material | Operation type | Machining | Cutting speed (m/min) | Feed(mm/rev) | DOC(mm) | Coolant |

|---|---|---|---|---|---|---|---|

| JX1/JX3 | Heat resistant alloys | Turning | Roughing (no scale) | 180 - 480 | 0.12 - 0.27 | 1.0 - 2.5 | WET |

| Profiling / Semi-finishing | 180 - 480 | 0.10 - 0.25 | 1.0 - 2.0 | ||||

| Grooving | 180 - 480 | 0.05 - 0.10 | - |

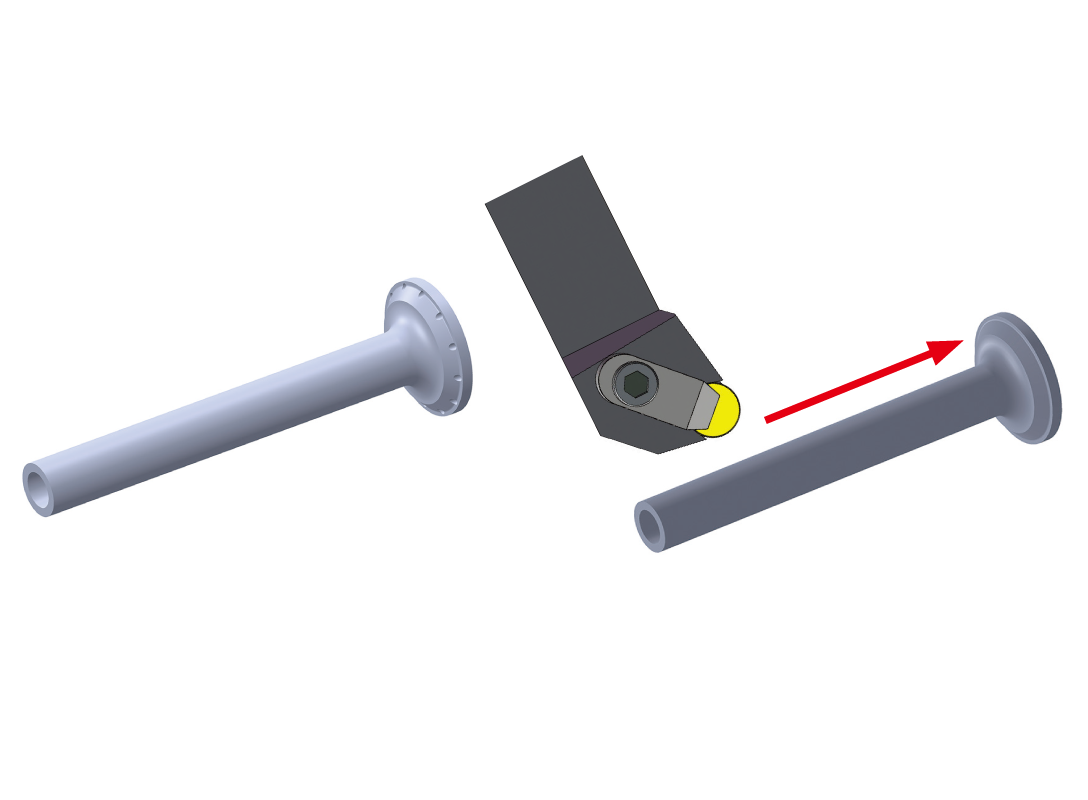

Rough (no scale) turning Inconel

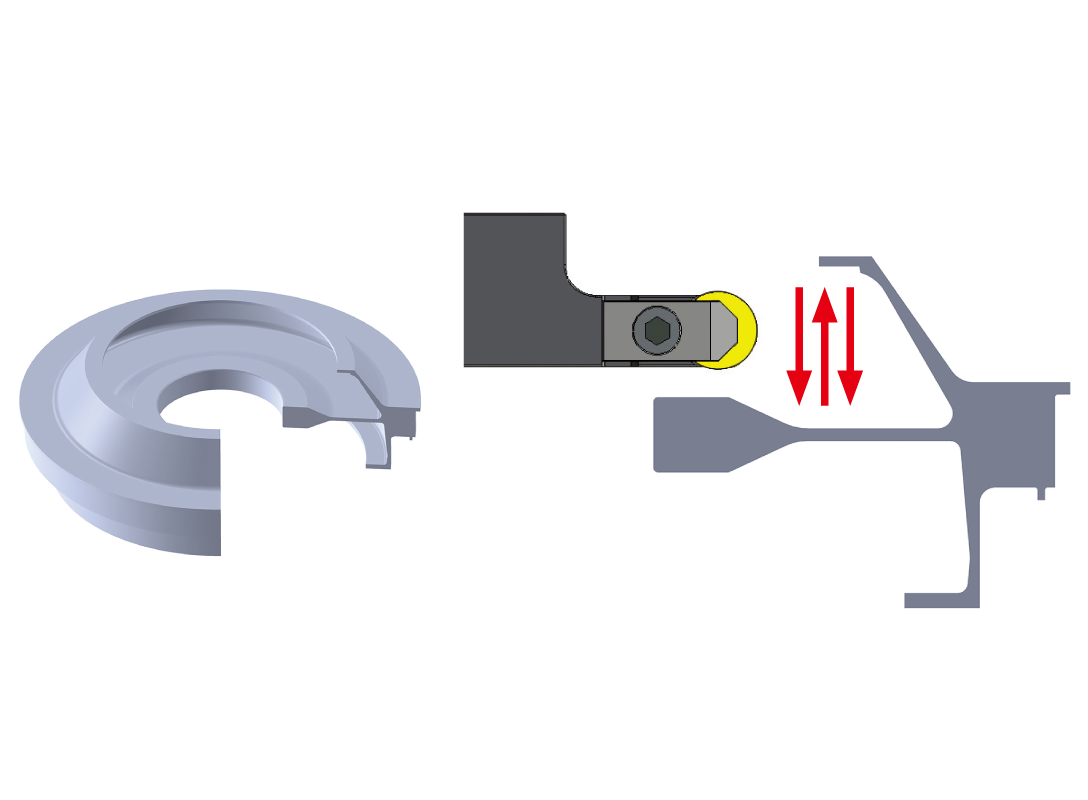

Grooving Inconel

Case study

| Turbine shaft (Inconel - no scale) | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| JX1 | 10min |

| Competitor's whisker ceramic | 3min |

- Long tool life

- JX1 combines strength and excellent thermal conductivity for improved performance compared to whisker ceramics.

BIDEMICS outperformed with dramatically better tool life when run at same parameters as the whisker ceramic insert.

| Turbine disc (Inconel - roughing) | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| JX1 | 120 cc/min |

| Competitor's whisker ceramic | 60 cc/min |

- Faster speeds

- BIDEMICS has excellent material characteristics to allow for high-speed machining.

JX1 machined at double the cutting speeds to improve productivity and eliminated the need for capital investments to improve production.

| Turbine case (Inco 718 Plus - semi-finishing) | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| JX1 | 3 pass |

| Competitor's coated whisker | 1 pass |

- Machines a wide range of heat resistant alloys

- Unique material characteristics of JX1/JX3 allow them to machine difficult to cut materials such as high nickel / high cobalt / powdered metals / heat resistant alloys which have recently become more common in the market.

Chip formation comparison

Continuous chips are typical when machining heat resistant alloys but at higher cutting speeds the chips break easily.

Tool lineup

Please check product catalog for tooling lineup

Other recommended products

-

NTK120/JP2Finishing Heat resistant alloys | BIDEMICS

Machine HRSA materials at speeds of Vc=500 m/min with BIDEMICS

-

SX3Roughing & semi-finishing heat resistant alloys | Sialon ceramic

First recommendation for heat resistant alloys machining

-

SX5Machine heavy scale & interruptions on heat resistant alloys| Sialon ceramic

Toughest SiAlON ceramic on the market

-

SX9Machines through scale on heat resistant alloys | Sialon ceramic

Excellent notch and flank wear resistant ceramic

Useful information

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕 Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕 Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics

Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics How to Make Ceramic Cutting Tools from Scratch

How to Make Ceramic Cutting Tools from Scratch