For front turning operations | Swiss CNC Lathes

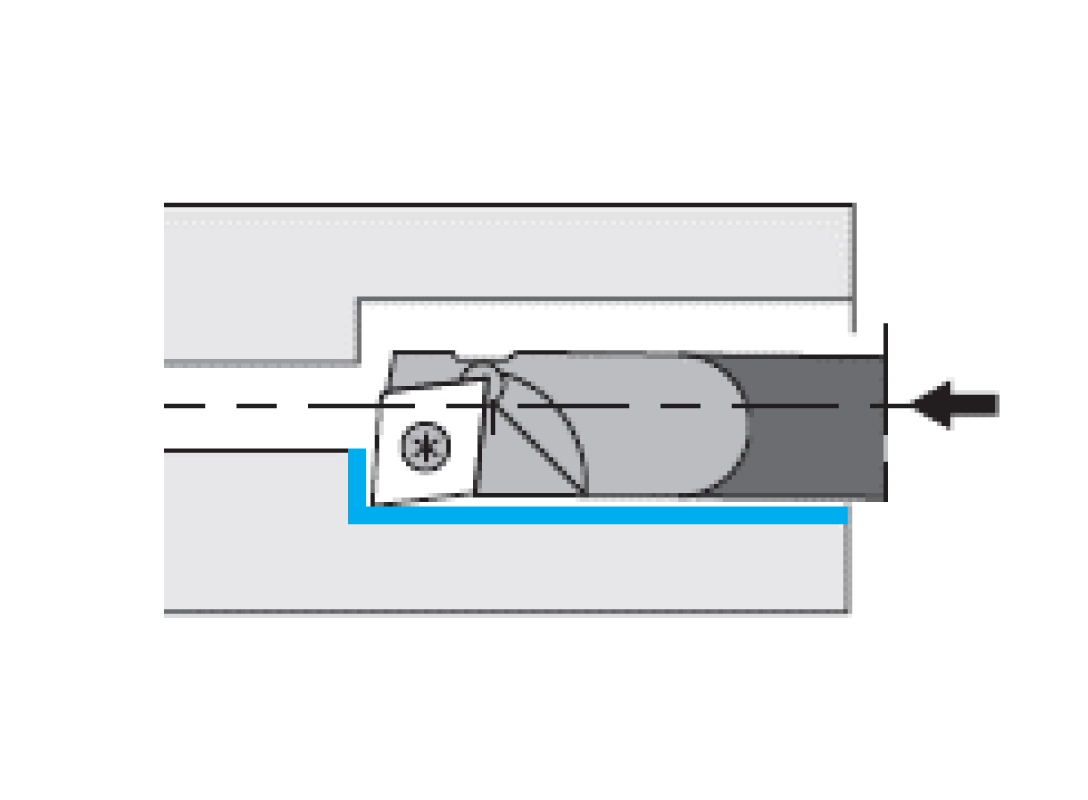

Swiss CNC Lathe front turning operations

Exceptional sharpness and low tool pressure for shearing material to ensure part accuracy

| Coated grade | Material | Operation type | Cutting speed (m/min) Cutting speed (SFM) | Feed (mm/rev) Feed (IPR) | DOC (mm) DOC (inch) |

|---|---|---|---|---|---|

| QM3 | Alloy steel / carbon steel / hardened material | OD Turning continuous | 50 – 120 150 – 400 | 0.02 – 0.10 .0004 – .0016 | 0.05 – 0.3 .002 – .012 |

| DM4/DT4 | Difficult-to-cut material / titanium alloy / stainless / high temp alloys | 30 – 100 75 – 330 | |||

| TM4 | Non-ferrous / aluminum / plastic / general purpose | 50 – 180 150 – 600 |

| Machine parts | |

|---|---|

|

|

|

|

|

|

|

|

|

|

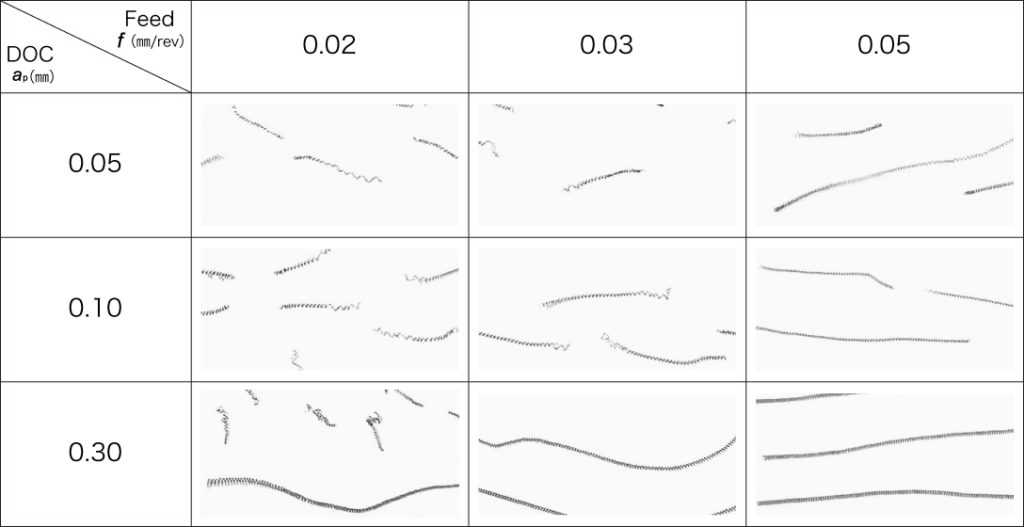

| DM4+ AMX chipbreaker |

10 pcs / corner

|

| Competitor’s molded chipbreaker (coated cermet) |

5pcs / corner

|

AMX achieved stable machining performance and good chip control.

For more information about this product, visit our online e-catalog, or download the catalog/product report

Other recommend products