Coolant through toolholders | Swiss CNC Lathes

Front turning / Back turning / Grooving / Threading / Cut off / ID boring

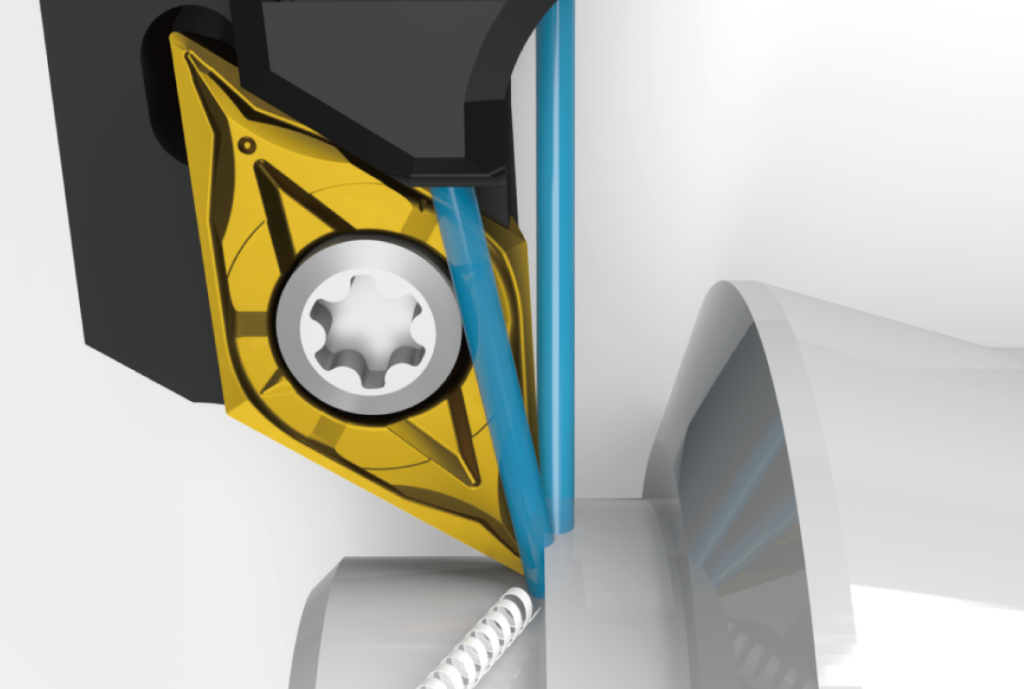

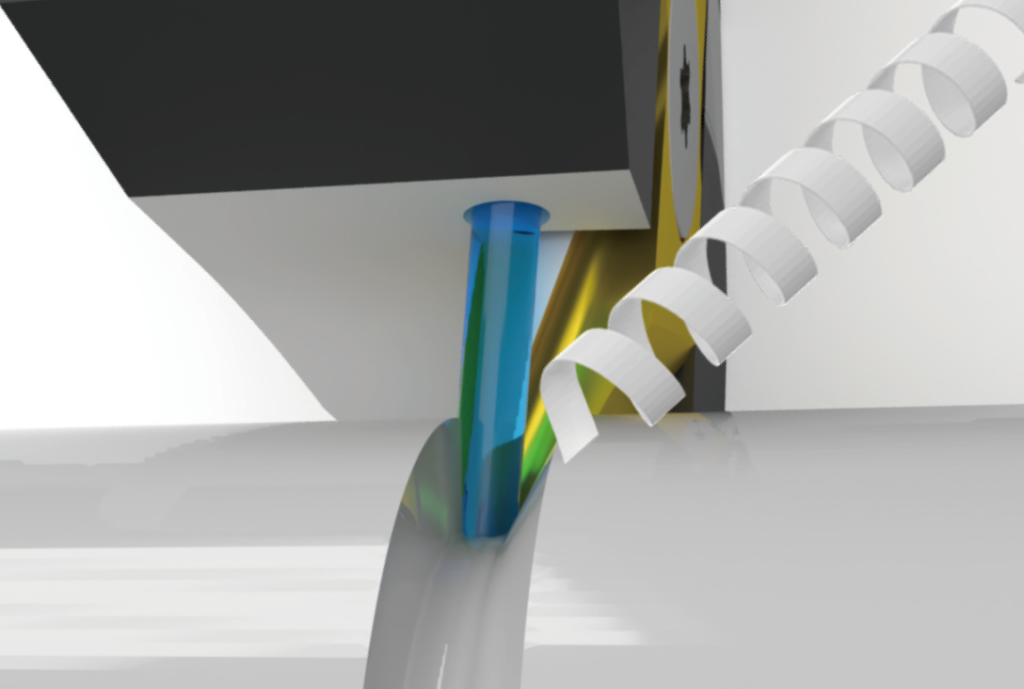

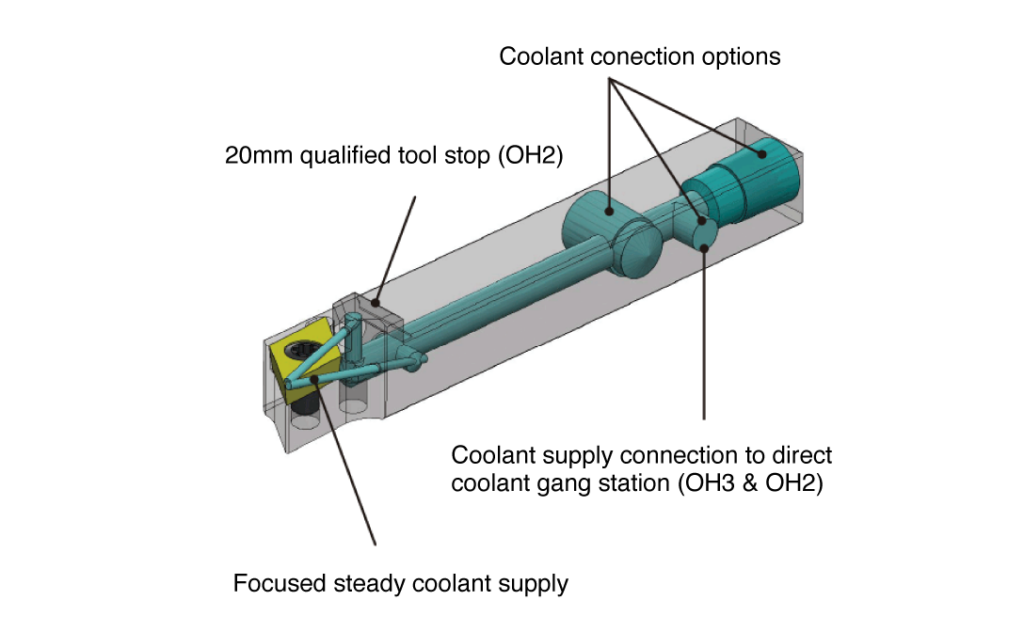

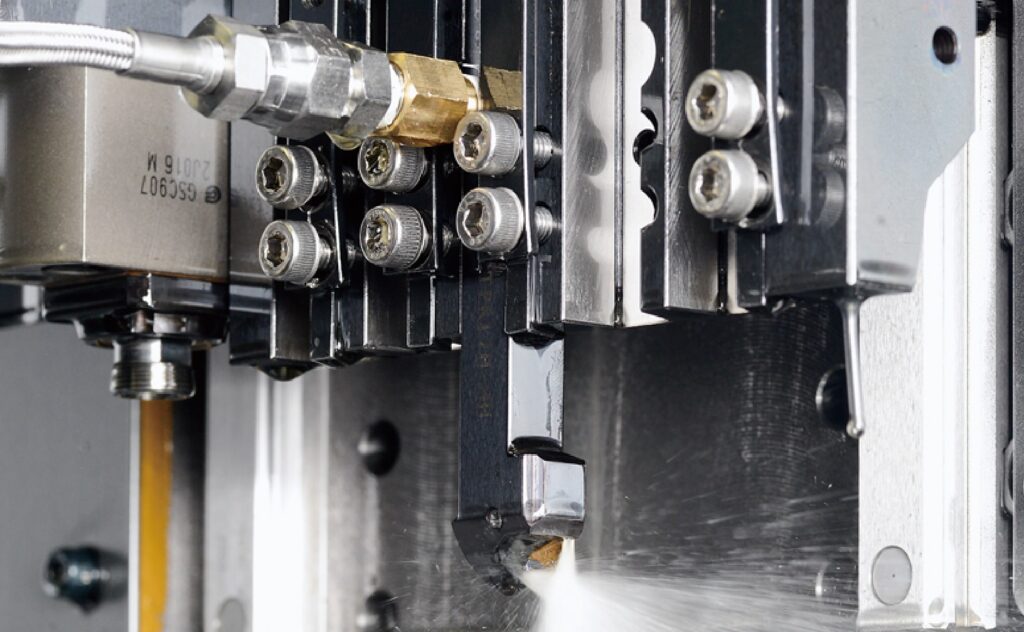

Coolant flow from two locations ( 12mm and 16mm .47” and .63” shank) directs the chips away from the guide bushing.

By focusing coolant to cutting edge chips are flushed away from the machined surface to achieve an excellent surface finish.

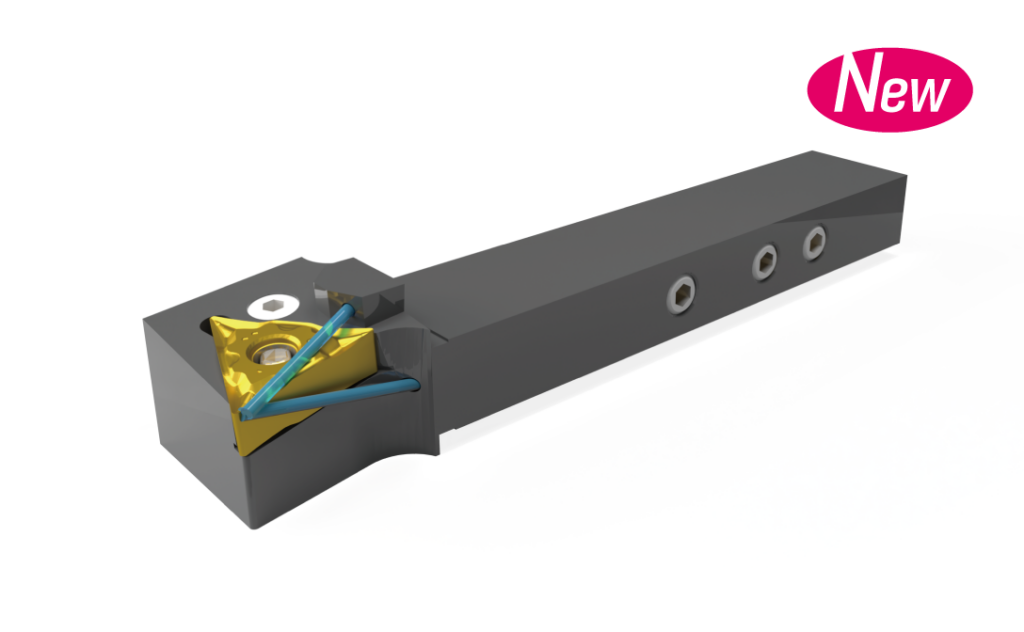

New CTP-SUB cut-off holder lineup

Lineup expansion of

16mm

.63”

sq. shank tools with direct connect capability

TNGG inserts with superior cost performance can be installed

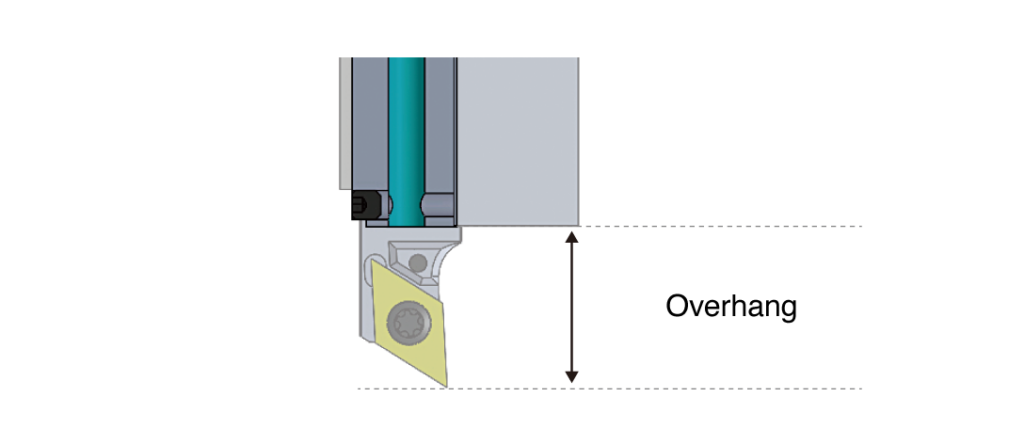

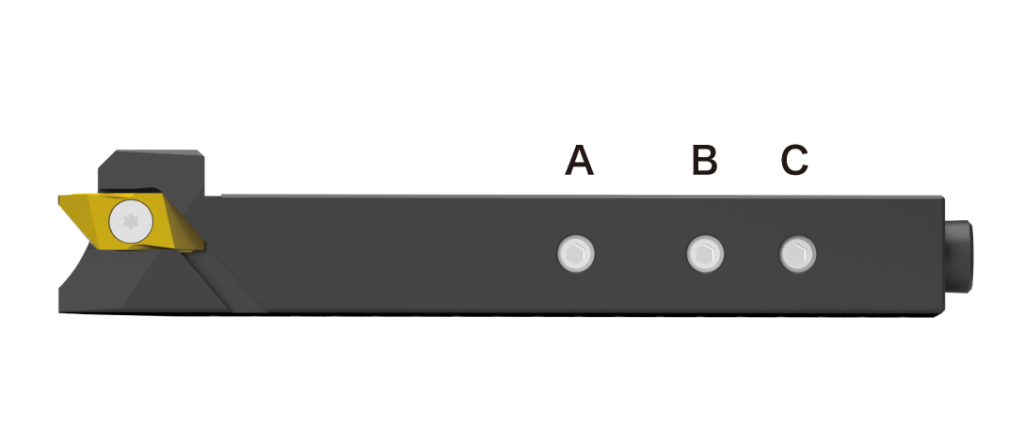

| Make* | Model | Tool position** | Shank size | Overhang (inch) | Direct Connect Toolholder Coolant Port |

|---|---|---|---|---|---|

| Citizen-Cincom | L12(2M) | T1 | □12 | 24.5mm .965 | C |

| T2-T7 | □10 | 17.5mm .689 | B | ||

| T2-T6 | □12 | ||||

| L20E(2M) | T1 | □12/16 | 30.0mm 1.181 | A | |

| T2-T5 | □12 | 20.0mm .787 | A | ||

| L20E(3M) | T1 | □12/16 | 30.0mm 1.181 | A | |

| T2-T6 | □12 | 20.0mm .787 | A | ||

| D25(1M) | T10 | □16/20 | 30.0mm 1.181 | C | |

| T11-T13 | □16 | 25.0mm .984 | |||

| T30 | □16/20 | ||||

| T31-T32 | □16 | ||||

| M32(5M) | T1 | □16/20 | |||

| T2-T5 | □16 | ||||

| STAR | SB-16Ⅲ | T1-T5(T6) | □12 | 22.0mm .866 | C |

| SD-26 Type-S,G,E,C | T1 | □16 | 30.0mm 1.181 | ||

| T2-T7 | 25.0mm .984 | ||||

| SB-20/23RⅡ | T1-T6 | □12 | 22.0mm .866 | ||

| T1 | □16 | 30.0mm 1.181 | |||

| T2-T5 | 25.0mm .984 | ||||

| TSUGAMI | B026/32-Ⅲ | T5-T9, T11-T15, T26-T27 | □16 | 26.0mm 1.024 | B |

| BW269/329ZJ | T5-T9, T26-T27 | ||||

| SS267/327-Ⅲ(-5AX) | |||||

| SS207-Ⅲ(-5AX) | T5-T10, T26-T28 | □12 | A | ||

| S205(A)/S206(A)-Ⅱ |

*Based on information from June 2025 ** The tool position varies depending on the option setting. Please confirm in advance.

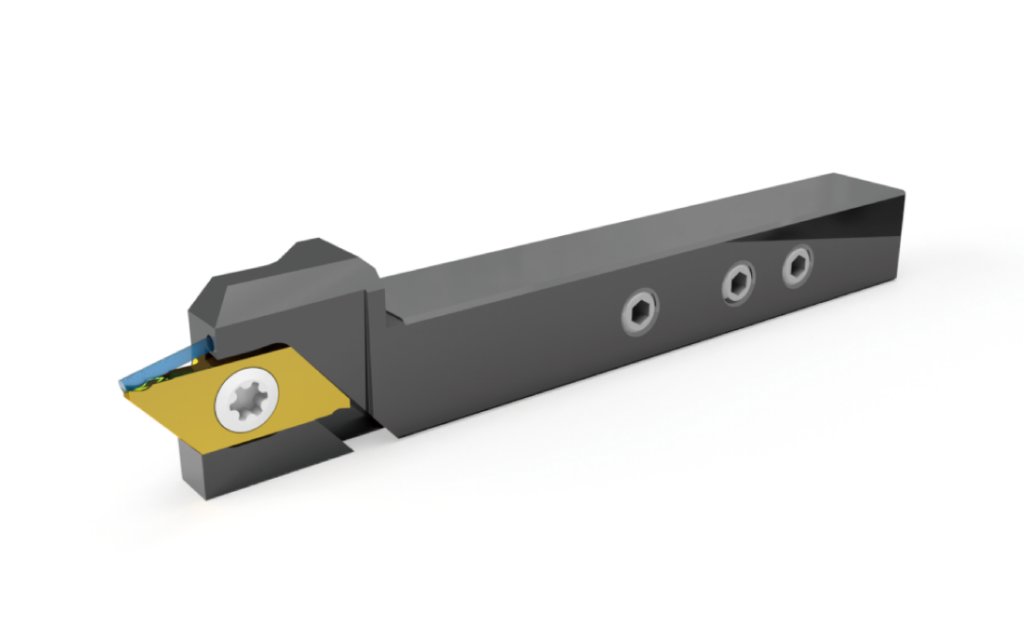

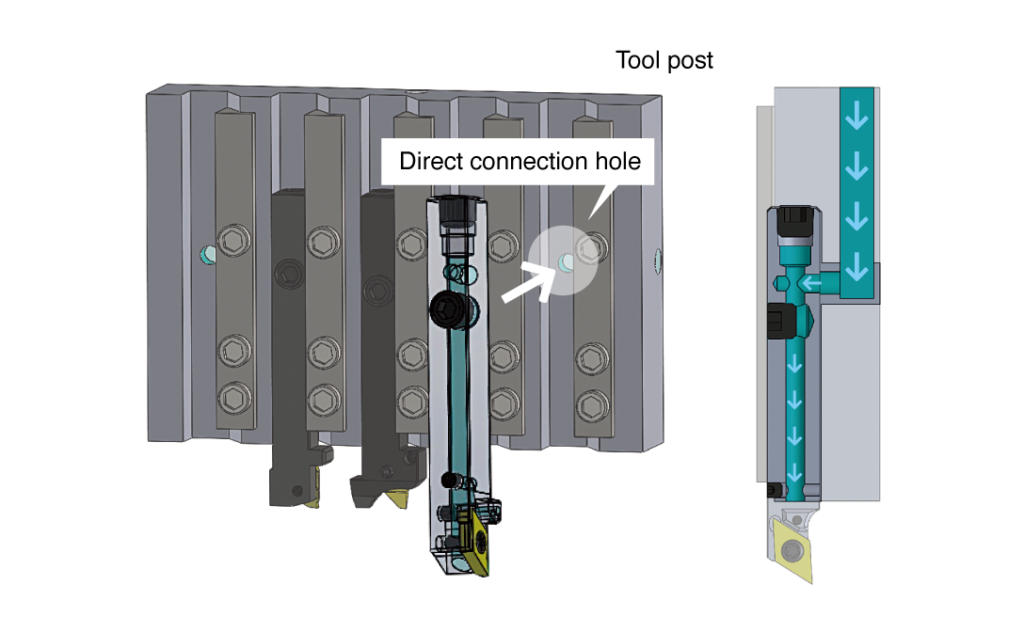

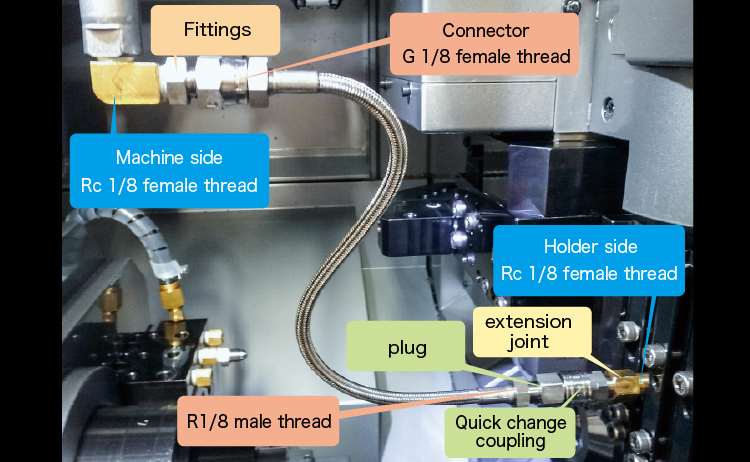

Holder side connection option

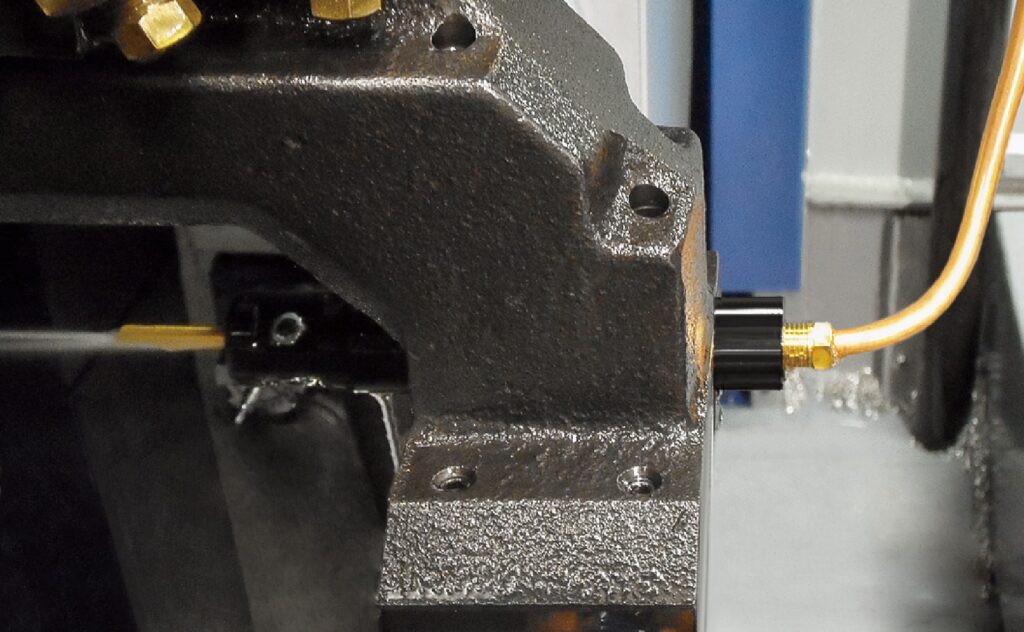

Holder rear connection option

ID boring holder side connection

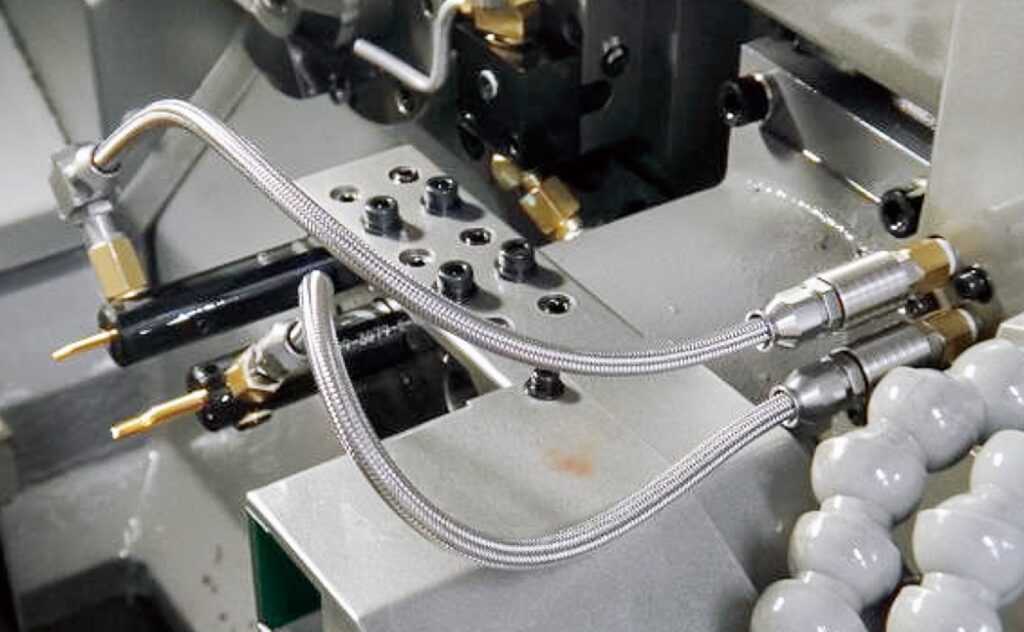

Hose mounting example (vertical gang style)

For more information about this product, visit our online e-catalog, or download the catalog/product report

Other recommend products