Best grade for machining stainless steel | Carbide grade for Swiss CNC lathes

For stainless steels and steels

Front turning / Back turning / Grooving / ID boring / Cut off / Threading

Expansion of lineup for all applications

Select optimum chipbreaker according to machining conditions

*Please refer to the catalog for details.

| Application | Series |

|---|---|

| Front turning | TMV chipbreaker AMX chipbreaker AM3 chipbreaker(with Wiper) |

| Back turning | BACK DUO series |

| Cut off | CUT DUO series |

| Threading | TTP series |

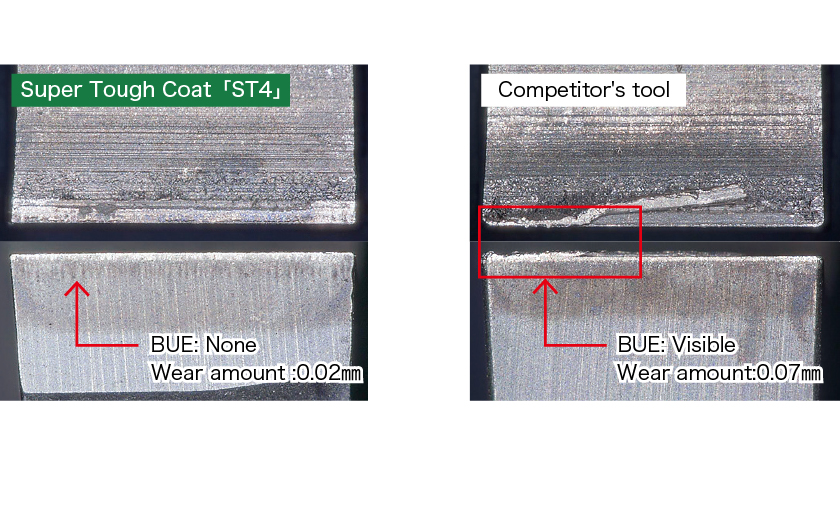

[ Cutting conditions ]

Material :

SUS304 ⌀11 vc=80m/min f=0.03㎜ /rev

304SS ⌀11 Speed=260 SFM feed=.0012”

after 200 pcs.

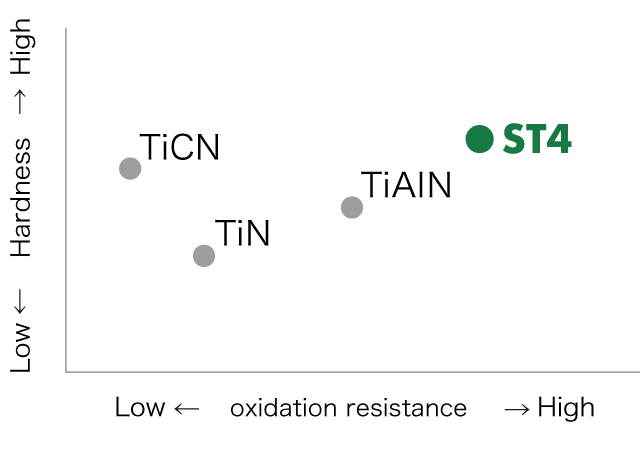

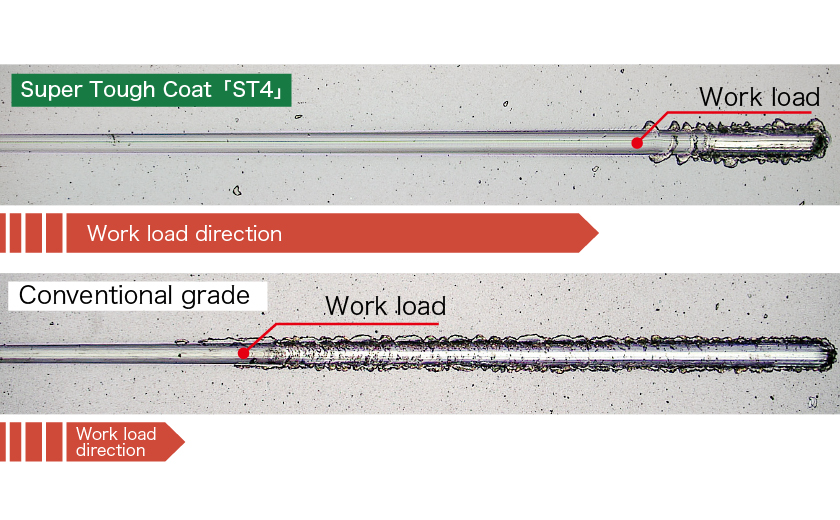

NTK’s new PVD coating technology improved the bonding force and smoothness on ST4.

It eliminates BUE issues and improves insert performance.

| Medical parts | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| ST4 | C/T About 1.5 min / part |

| Conventional tool (PVD carbide) |

C/T About 5.0 min / part

|

TFX series insert in ST4 achieved approximately 3.7 times lower cycle time than that of the competitor’s insert.

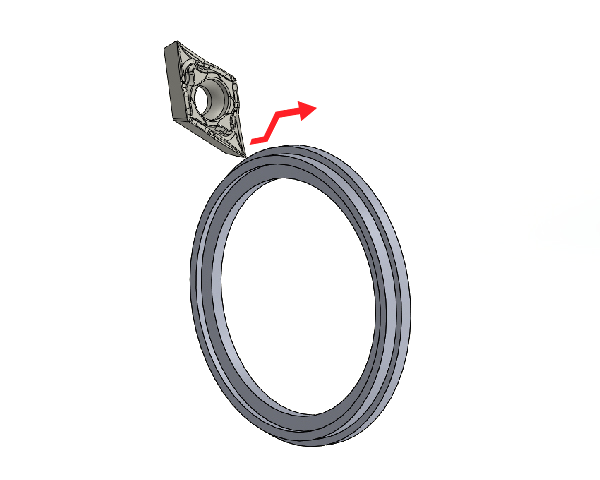

| Pipe part | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| ST4 |

2,000 pcs / corner

|

| Conventional tool (PVD carbide) |

1000 pcs / corner

|

ST4 increased tool life by 2 times that of the competitor insert.

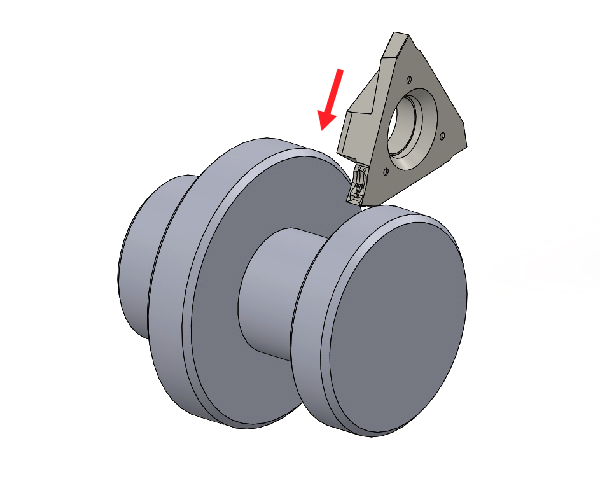

| Machine parts | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| ST4 |

6,000 pcs / corner

|

| Conventional tool (PVD carbide) |

3,500 pcs / corner

|

ST4 increased tool life by about 1.7 times compared to the competition.

| Equipment parts | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| ST4 |

4000 pcs / corner

|

| Conventional tool (PVD carbide) |

2000 pcs / corner

|

ST4 achieved 2 times the tool life of the competitor’s insert.

For more information about this product, visit our online e-catalog, or download the catalog/product report