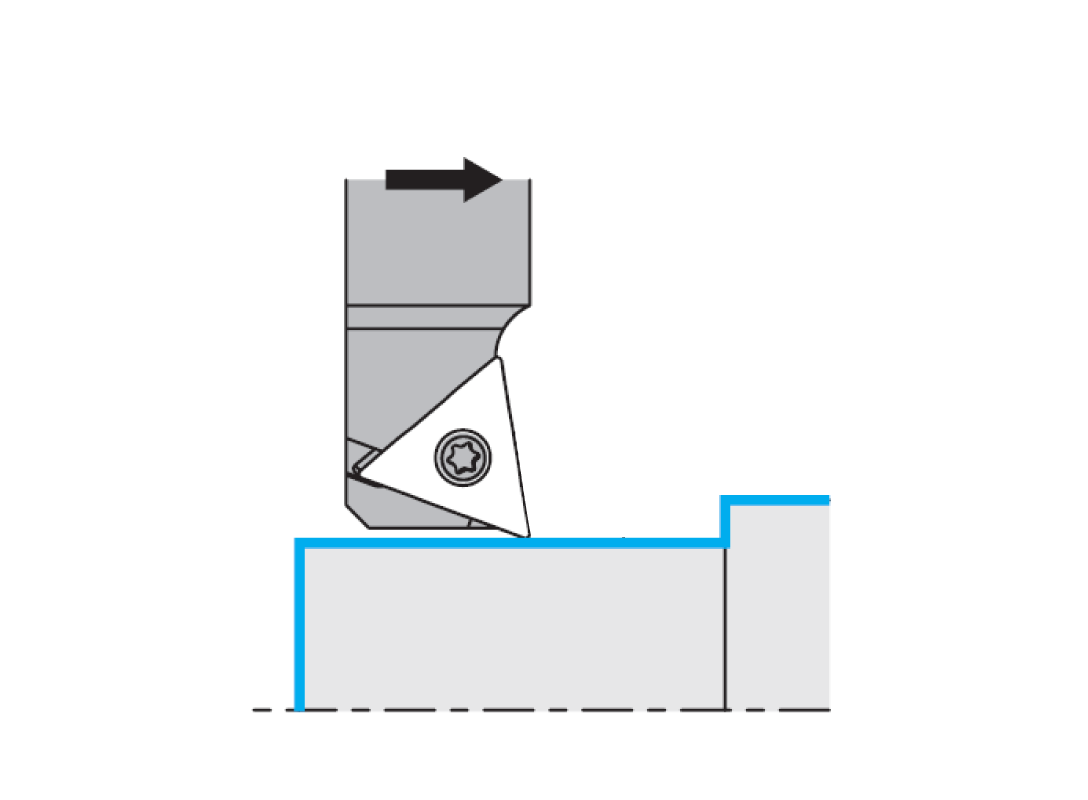

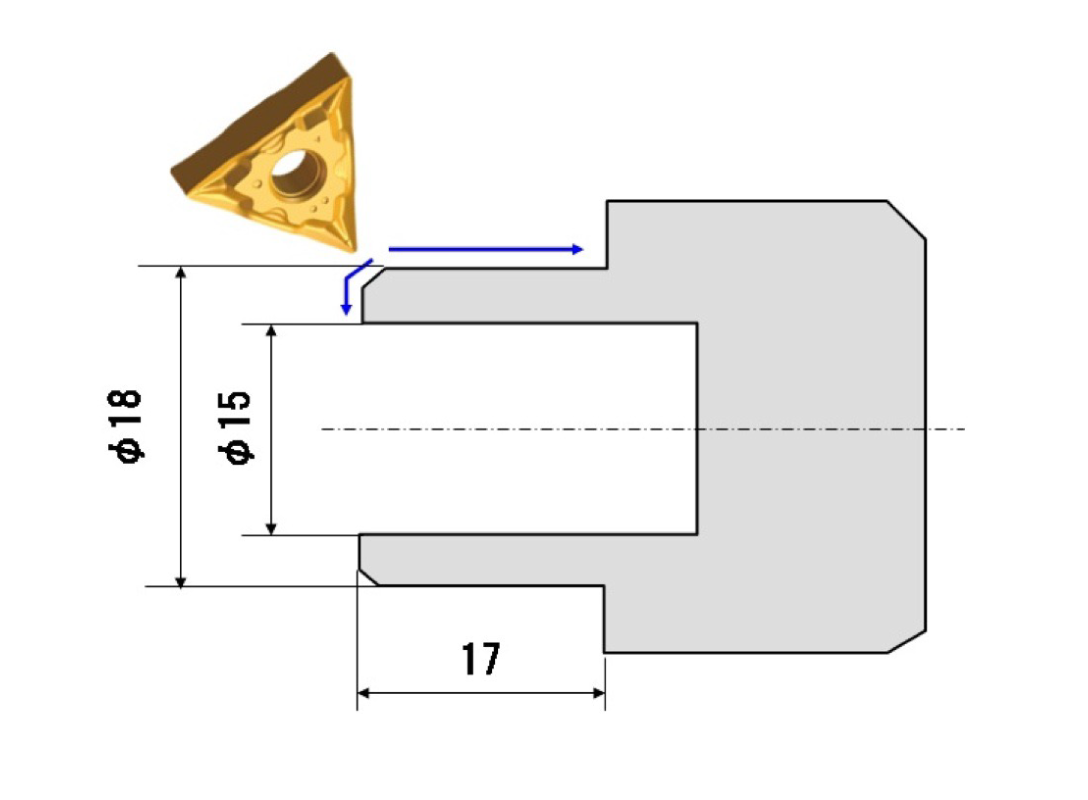

For front turning operations | Swiss CNC Lathes

Swiss CNC Lathe front turning operations

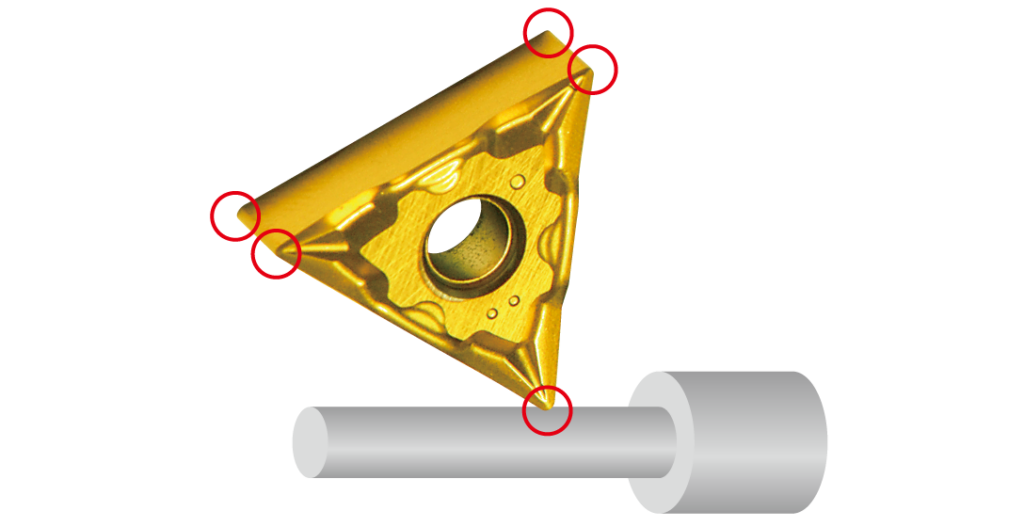

Achieves performance comparable to a positive insert with the benefit of additional corners

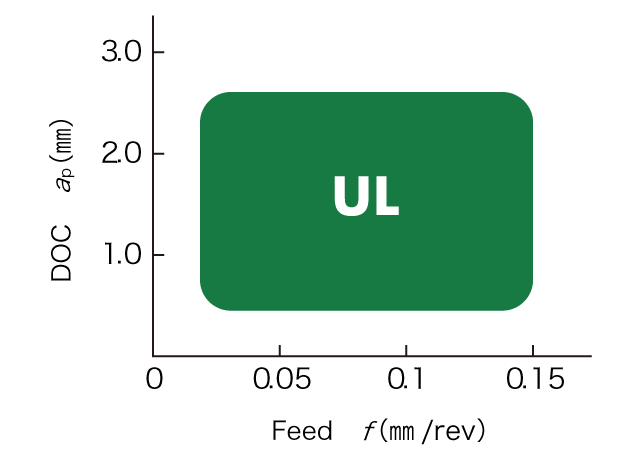

| Coated grade | Material | Operation type | Cutting speed (m/min) Cutting speed (SFM) | Feed (mm/rev) Feed (IPR) | DOC (mm) DOC (inch) |

|---|---|---|---|---|---|

| ST4 | Stainless | OD Turning continuous | 50 – 120 150 – 400 | 0.03 – 0.15 .0008 – .004 | 0.3 – 2.5 .020 – .118 |

| QM3 | Alloy steel / carbon steel / hardened material | ||||

| DM4 | Difficult-to-cut material / titanium alloy / high temp alloys | 30 – 100 75 – 330 | |||

| TM4 | Non-ferrous / aluminum / plastic / general purpose | 50 – 180 150 – 600 |

| Electronic component | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| ST4+ UL chipbreaker |

1000 pcs / corner

|

| Competitor’s molded chipbreaker (PVD coated carbide) | 200 pcs / corner |

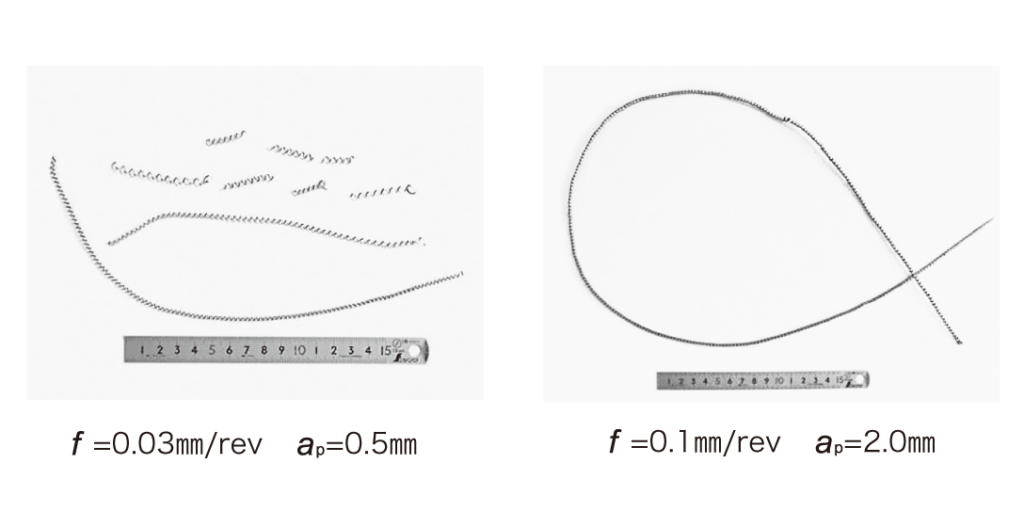

UL insert obtained good machined surface with its sharp cutting edge.

UL combined with the ST4 grade, for stainless steel machining, achieved 4 x longer tool life compared to the competition.

| Auto parts | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| TM4+ UL chipbreaker |

800 pcs / corner

|

| Competitor’s wiper insert (PVD coated carbide) |

400 pcs / corner

|

UL sharpness provided stable dimensional results and reduced tool pressure

When cutting speed increased, BUE was eliminated further increasing tool life from 600 to 800 pieces /corner

For more information about this product, visit our online e-catalog, or download the catalog/product report