For continuous machining | NTK CeramiX

Hardened materialContinuous machining HRC55-65

| Grade | Material | Operation type | Machining | Cutting speed (m/min) Cutting speed (SFM) | Feed (mm/rev) Feed (IPR) | DOC (mm) DOC (Inch) | DRY | WET |

|---|---|---|---|---|---|---|---|---|

| NTK450 | Hardened material (HRC55-65) |

Turning | Finishing | 100 – 200 330 – 660 | 0.08 – 0.15 .003 – .006 | 0.1 – 0.5 .004 – .020 | ● | ● |

| The same conditions as current CBN | ||||||||

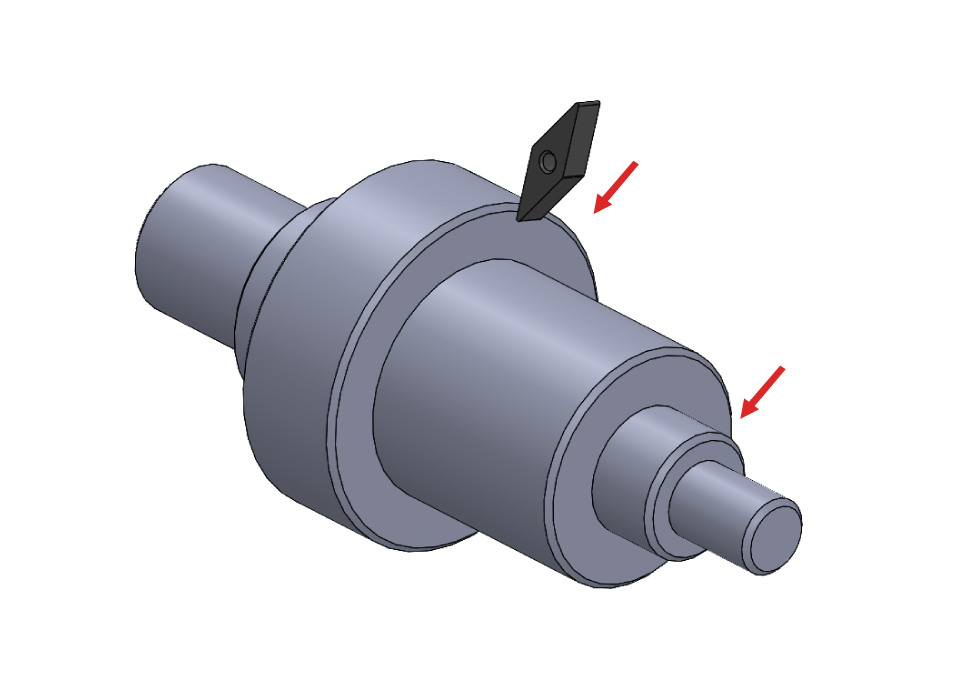

| Industrial robot component | |

|---|---|

|

part diameter :

φ60

φ2.36 inches part diameter :

φ60

φ2.36 inches

|

|

|

|

|

|

|

|

|

| NTK450 TNGA160404 TNGA331 |

30 pcs / corner

|

| Competitor’s coated CBN |

15pcs / corner

|

NTK450 achieved double the tool life vs. the competitor’s coated CBN insert.

Switching to CeramiX will result in a 70% reduction in tool cost per year.

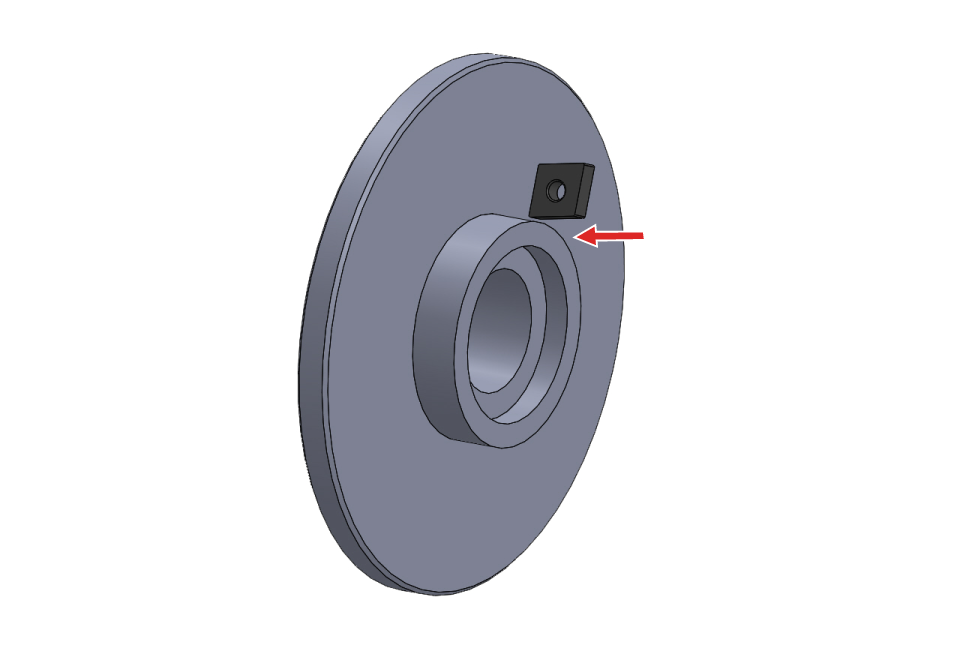

| Gear | |

|---|---|

|

part diameter :

φ150

φ6 inches part diameter :

φ150

φ6 inches

|

|

|

|

|

|

|

|

|

| NTK450 CNGA120404 CNGA431 |

200 pcs / corner

|

| Competitor’s coated CBN |

200 pcs / corner

|

NTK450 matched the tool life of the competitor’s coated CBN.

The result is a 50% reduction in insert costs for the customer.

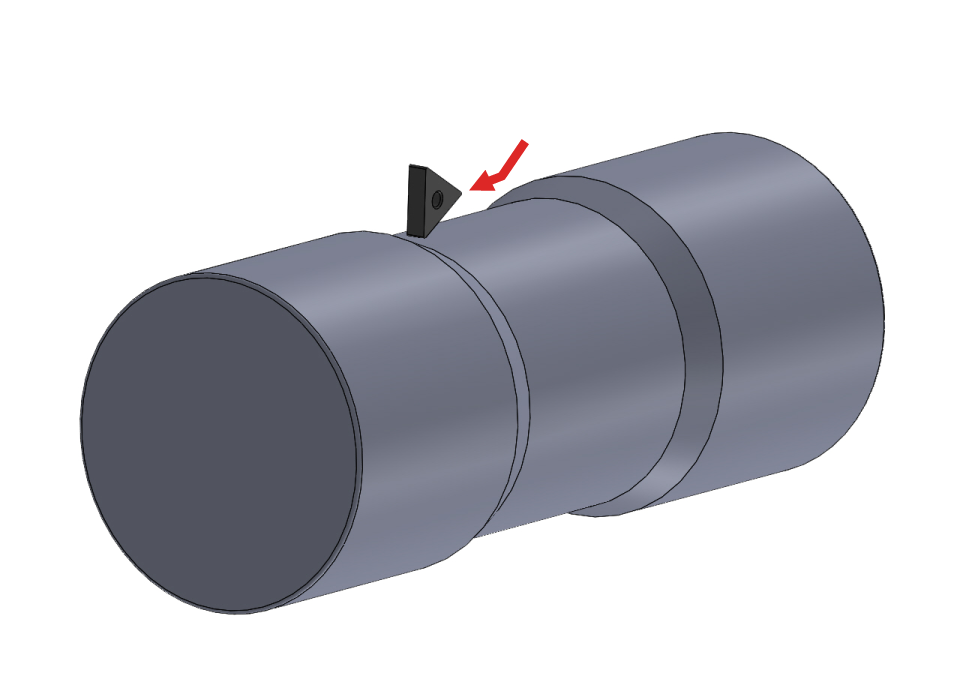

| Holder part | |

|---|---|

|

part diameter :

φ60

φ2.36 inches part diameter :

φ60

φ2.36 inches

|

|

|

|

|

|

|

|

|

| NTK450 VNGA160404 VNGA331 |

20 pcs / corner

|

| Competitor’s CBN |

20 pcs / corner

|

NTK450 matched the tool life of the competitor’s coated CBN.

The result is a 30% reduction in insert costs with NTK450.

| Industrial part | |

|---|---|

|

part diameter :

φ250

φ10 inches part diameter :

φ250

φ10 inches

|

|

|

|

|

|

|

|

|

| NTK450 TNGA160404 |

16pcs / corner

|

| Competitor’s coated CBN |

20 pcs / corner

|

NTK450 achieved 80% of the tool life compared to competitor’s coated CBN with the same cutting conditions.

Replacing the CBN with NTK450 will result in a 10% tool cost reduction for the customer.

For more information about this product, visit our online e-catalog, or download the catalog/product report

Other recommend products