Finishing Heat resistant alloys | BIDEMICS

Finishing Heat resistant alloys

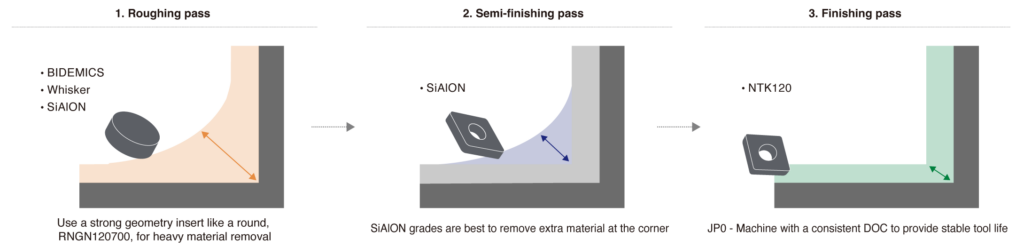

Finish turning operations

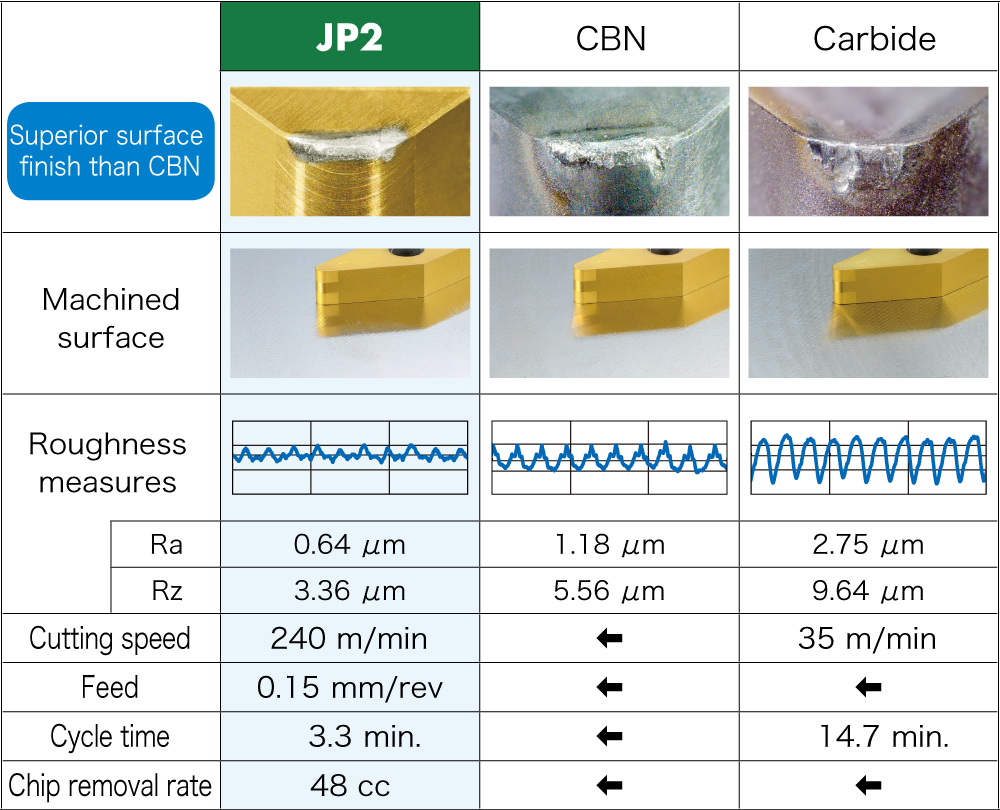

JP2’s excellent wear resistance and notching resistance results in workpiece surface finishes consistently superior to both CBN and carbide.

| Grade | Material | Operation type | Machining | Cutting speed (m/min) Cutting speed (SFM) | Feed(mm/rev) Feed(IPR) | DOC(mm) DOC(inch) | Coolant |

|---|---|---|---|---|---|---|---|

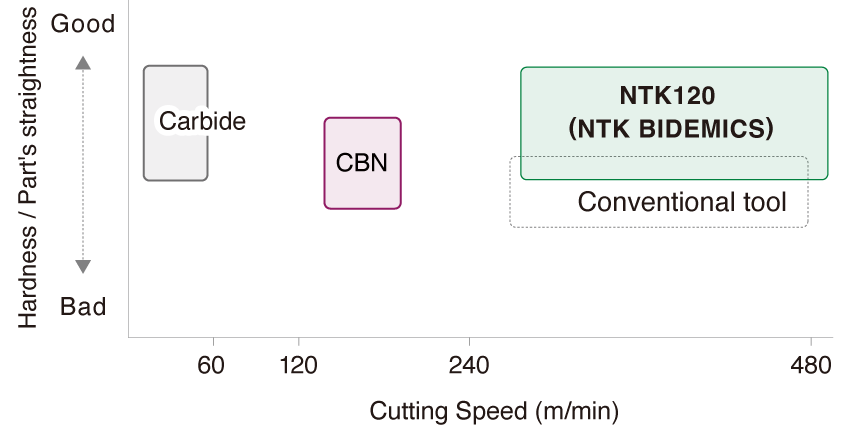

| NTK120 | Heat resistant alloys | Turning | Finishing | 180 – 500 600 – 1600 | 0.05 – 0.20 .002 – .006 | 0.1 – 0.7 .004 – .015 | WET |

| JP2 | 180 – 480 600 – 1600 | 0.10 – 0.25 .002 – .007 | 0.2 – 1.0 .004 – .015 |

For more information about this product, visit our online e-catalog, or download the catalog/product report

Other recommend products