Machines through scale on heat resistant alloys | Sialon ceramic

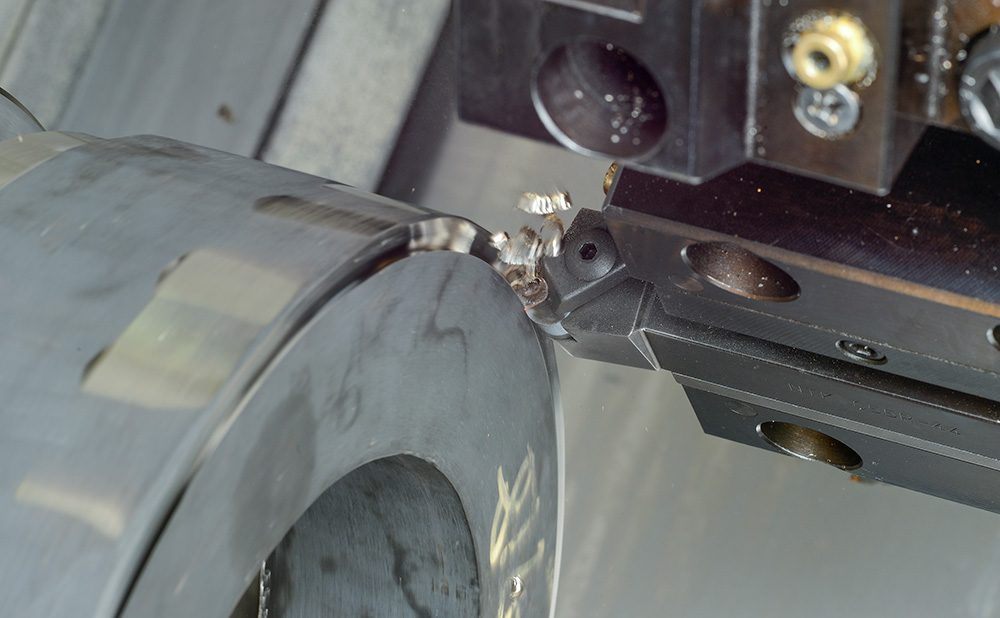

Heat resistant alloys

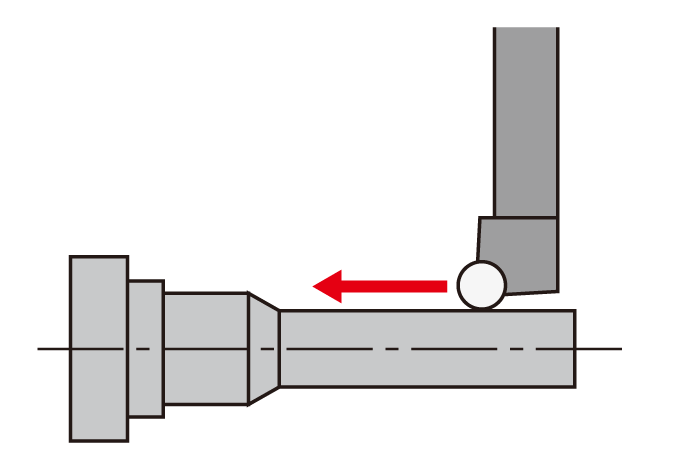

Turning / Milling / End milling: roughing operations

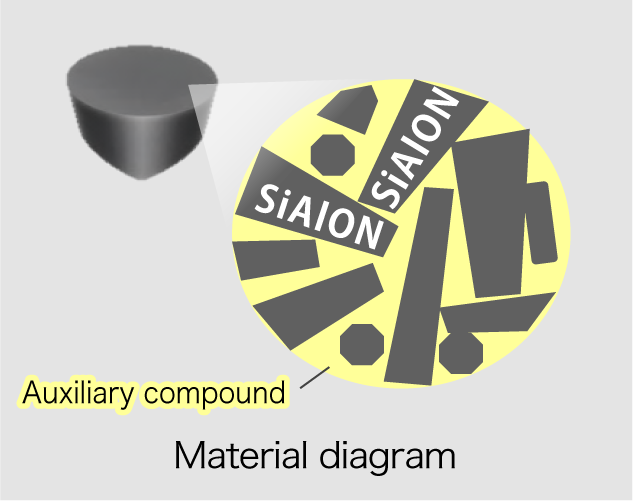

氮化硅(Si3N4)与铝(Al)和氧(O)结合制成 SiAlON。

Sialon 具有与氮化硅类似的针状颗粒。

这些颗粒的排列使材料能够承受切削时的冲击力。

氧化铝的加入提高了材料的耐热性能。

这些性能优势使其成为加工耐热合金的理想材料。

| 等级 | 材料 | 操作类型 | 机械加工 | Cutting speed (m/min) Cutting speed (SFM) | Feed(mm/rev) Feed (IPR / IPT) | DOC(mm) DOC(inch) | 冷却液 |

|---|---|---|---|---|---|---|---|

| SX9 | 耐热合金 | Turning | Roughing (scale or no scale) | 180 – 240 600 – 800 | 0.20 – 0.35 .008 – .014 | 1.0 – 5.0 .040 – .200 | 湿润 |

| 轮廓加工/半精加工 | 180 – 270 600 – 900 | 0.15 – 0.30 .006 – .012 | 1.0 – 2.0 .040 – .080 | ||||

| Milling | 可索引 | 450 – 1000 1500 – 3300 | 0.02 – 0.03 .0008 – .001 | 1.0 – 2.5 .040 – .100 | 干燥 | ||

| 端铣 | – | 300 – 1000 1000 – 3300 | 0.05 – 0.1 .002 – .004 | – |

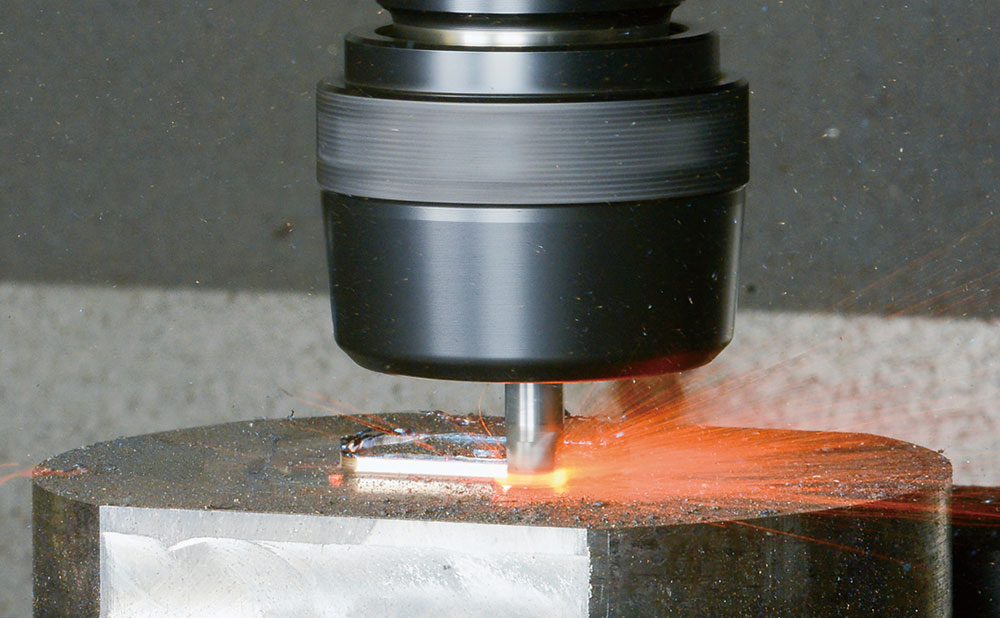

| Aircraft part (with scale) | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| SX9 |

2 pcs / corner

|

| Competitor’s whisker |

1 pcs / corner

|

SX9 is a significant cost advantage and double the tool life compared to competitor’s whisker insert.

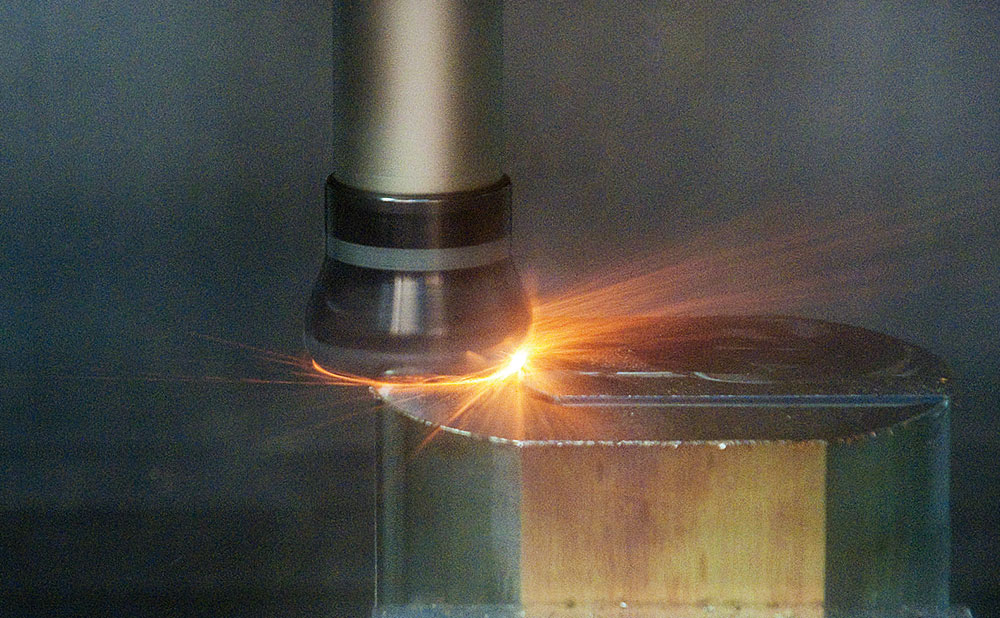

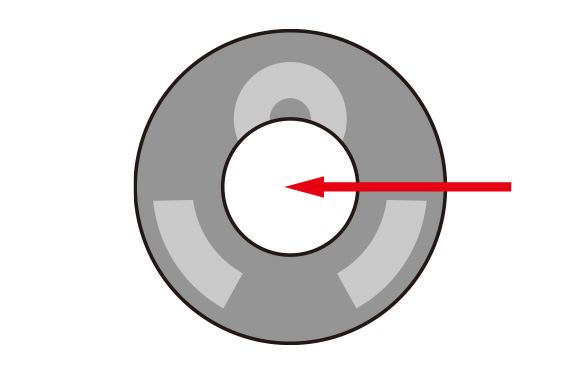

| Ring (with scale) | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| SX9 |

10 pass

|

| Competitor’s whisker |

5 通过

|

与竞争对手的晶须级相比,SX9 的刀具寿命延长了一倍。