金属增材制造工作粗加工 | Sialon 陶瓷

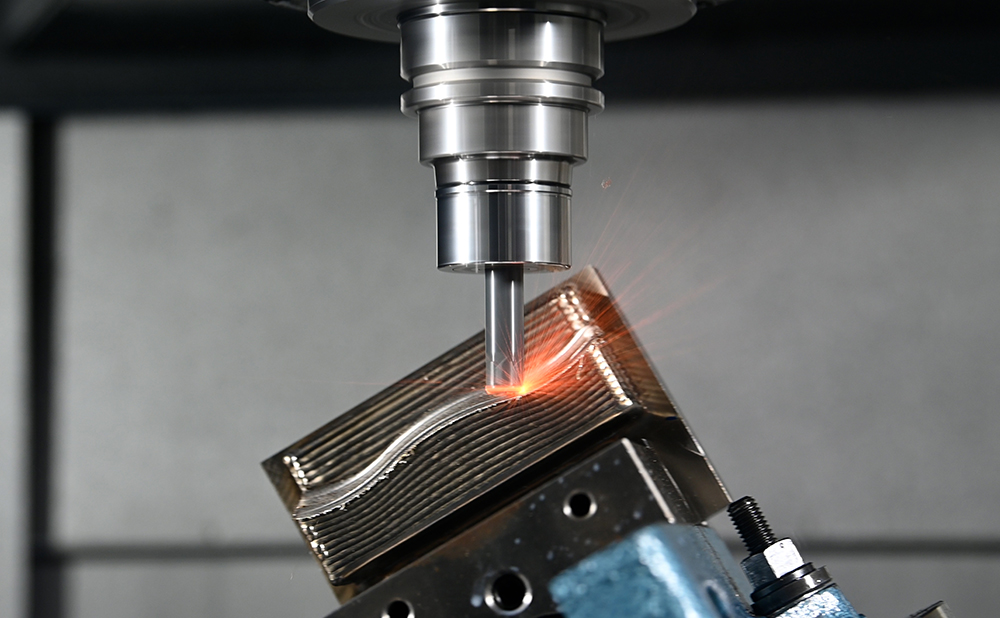

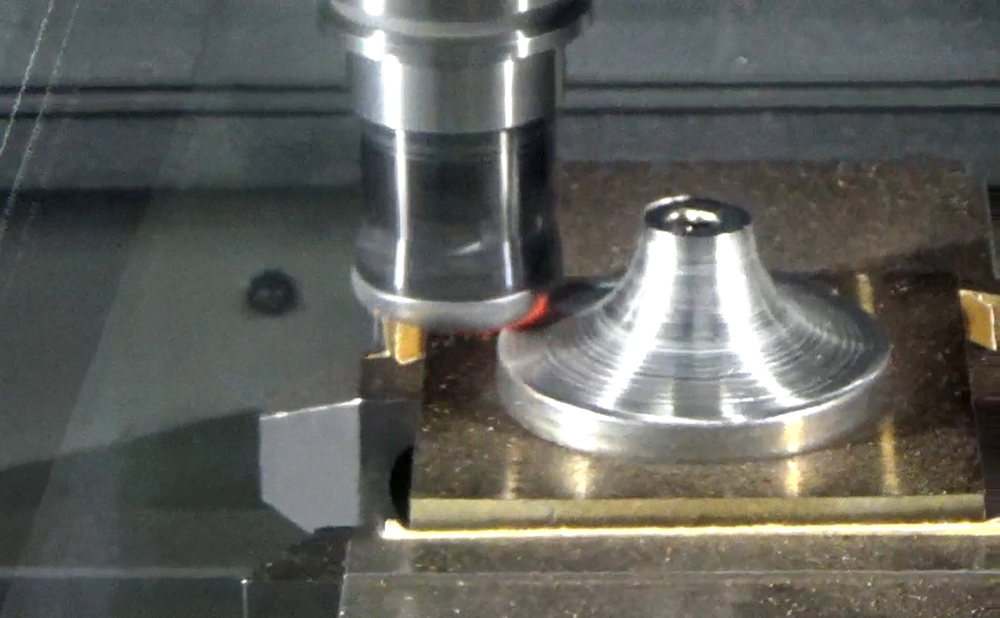

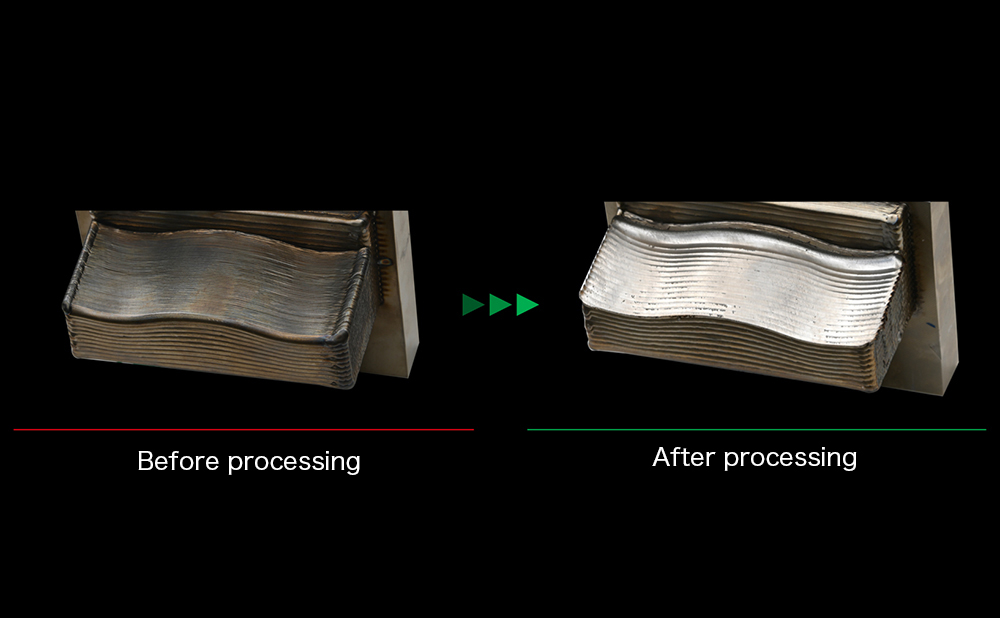

Additively manufactured workpieces using nickel-based alloys

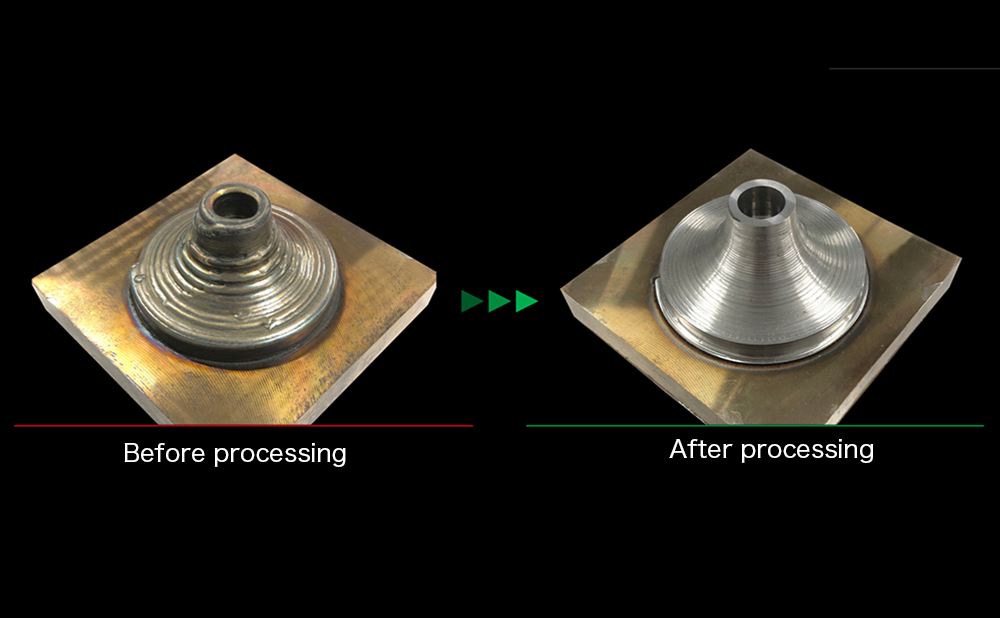

Milling / End milling: roughing operations

Machining that takes about 8 minutes with a carbide tool can be shortened to about 1 minute with a ceramic tool.

Achieves high-efficiency machining approximately 20 times that of carbide tools.

| Grade | Material | Operation type | Machining | Cutting speed (m/min) Cutting speed (SFM) | Feed (mm/t) Feed (IPT) | DOC (mm) DOC (inch) | Coolant |

|---|---|---|---|---|---|---|---|

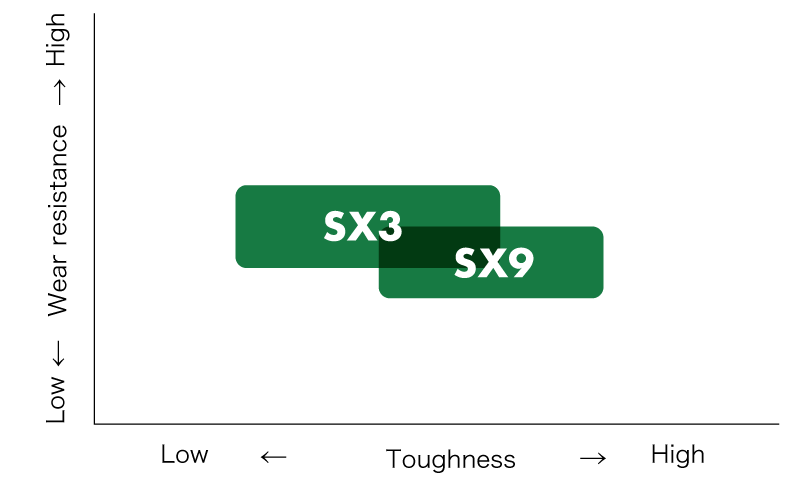

| SX3 / SX9 | Additive manufacturing workpiece (Nickel-based alloy) | Milling | Roughing | 450 – 1,000 1500 – 3500 | 0.07 – 0.12 .003 – .005 | – | DRY |

| SX9 | End milling | 300 – 1,000 1000 – 3300 | 0.03 .001 | – |

For more information about this product, visit our online e-catalog, or download the catalog/product report