High-speed finishing of gray cast iron| Uncoated CBNs

High-speed finishing of gray cast iron| Uncoated CBNs

Best CBN grades for machining gray cast iron

High-speed machining up to Vc=~1,200m/min

Highly effective machining even surpassing ceramic

Features

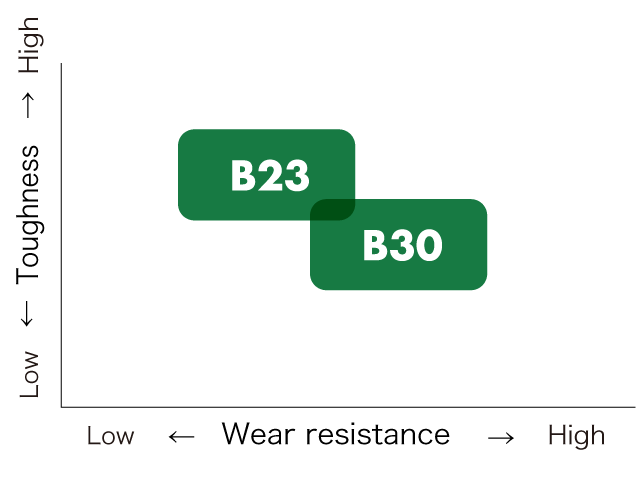

- B23 & B30 grades have high CBN content to enhance wear resistance characteristics

- Perform ultra-high speed machining of up to Vc-1,200 m / min

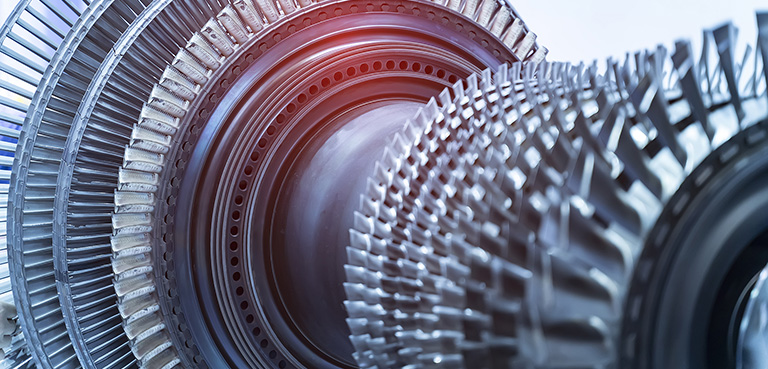

Tooling application

Gray cast iron

B23 for roughing to semi-finish turning operations

B30 for semi-finish to finish turning operations

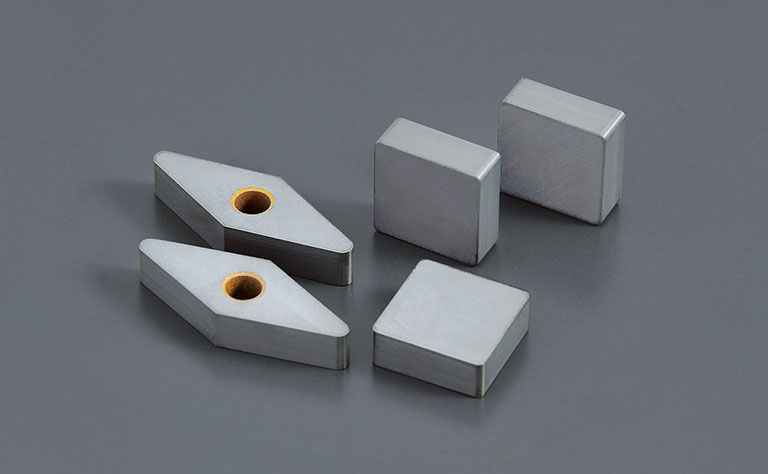

Grade characteristics

Cutting conditions

Scroll the table →

| Grade | Material | Operation type | Machining | Cutting speed (m/min) | Feed(mm/rev) | DOC(mm) | Coolant |

|---|---|---|---|---|---|---|---|

| B23/B30 | Gray cast iron | Turning | High-speed finishing | 400 - 1200 | 0.1 - 0.5 | -2.0 | DRY/WET |

Cost effective: Double-sided & multi-cornered CBN

Case study

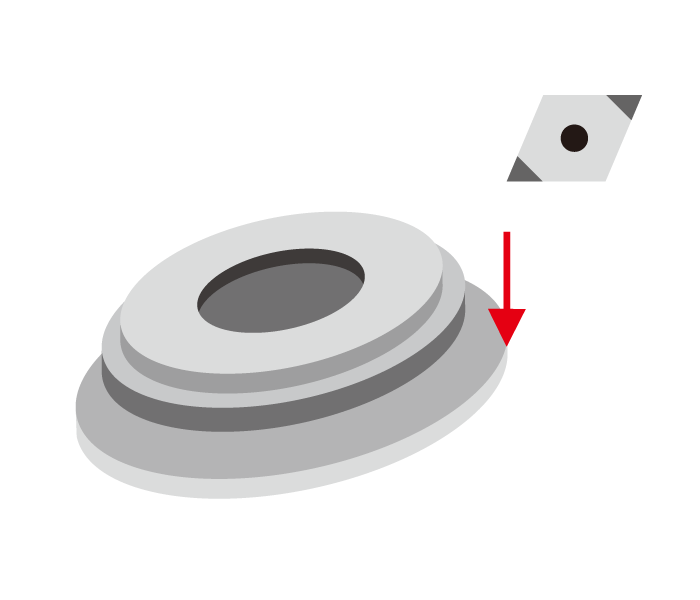

| OD turning of oil pump housing | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| B23 | 210 pcs / corner |

| Competitor's CBN | 70 pcs / corner |

- The B23 insert was 3 times more productive than the competitor's insert.

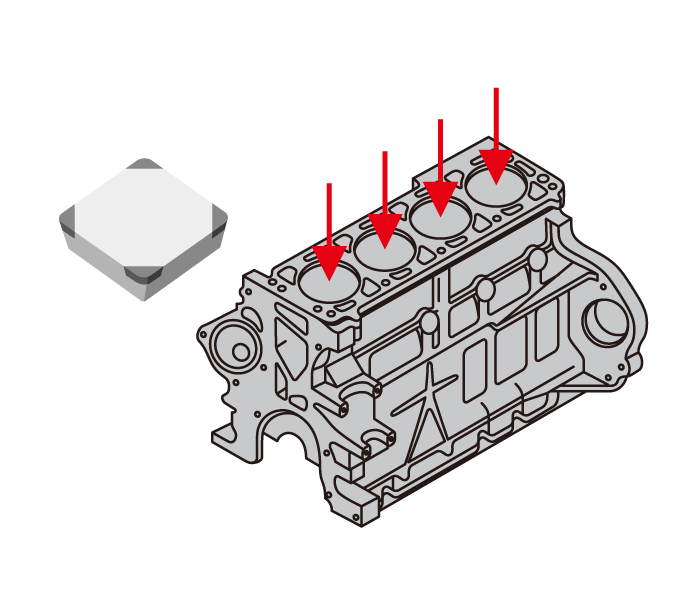

| Continuous ID bore operation on a cylinder block | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| B30 | 800 pcs / corner |

| Competitor's CBN | 500 pcs / corner |

- B30 achieved 1.6 times the tool life compared to competitor's CBN.

Tool lineup

Please check product catalog for tooling lineup

Other recommended products

-

HC1/HW2Continuous machining of gray cast iron| Alumina ceramic (White ceramics)

First recommendation for finishing gray cast iron

-

HC6For machining ductile cast iron| TiC ceramic + alumina

Specialized ceramic for finishing ductile iron

-

SP9Roughing to finishing of ductile cast iron & gray cast iron| Coated Silicon Nitride Ceramic

Covers roughing to finishing operations

-

SX6Exceptional wear resistance for rough machining of gray cast iron| Silicon nitride ceramic

First recommendation for roughing gray cast iron

Useful information

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕 Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕 Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics

Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics How to Make Ceramic Cutting Tools from Scratch

How to Make Ceramic Cutting Tools from Scratch